High Temperature Composite Resin Market Analysis and Global Forecast 2023-2033

$ 1,390.00 – $ 5,520.00

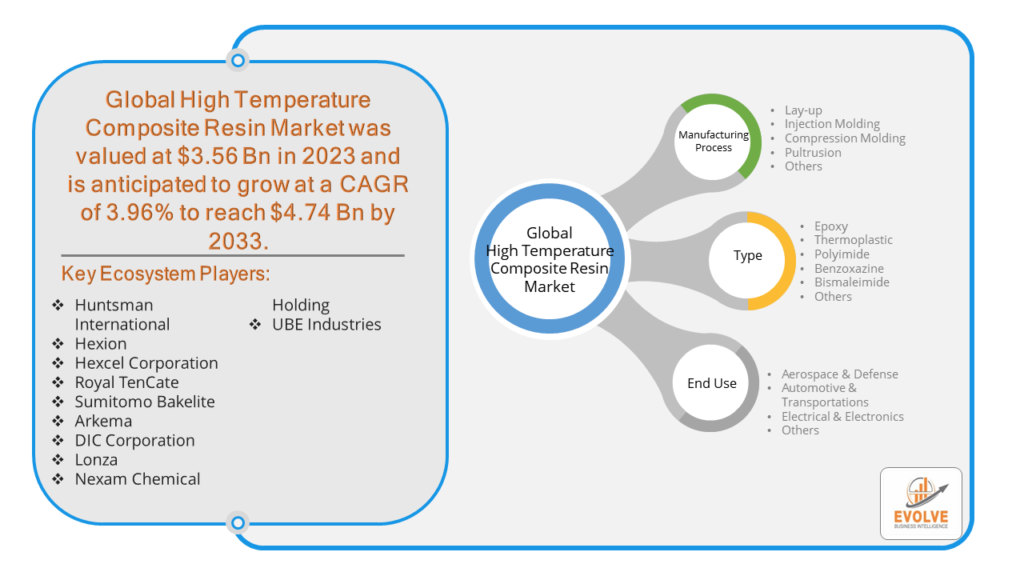

High-Temperature Composite Resin Market Research Report: By Manufacturing Process (Lay-up, Injection Molding, Compression Molding, Pultrusion, Others), By Type (Epoxy, Thermoplastic, Polyimide, Benzoxazine, Bismaleimide, Others), By End-Use (Aerospace & Defense, Automotive & Transportations, Electrical & Electronics, Others), and by Region — Forecast till 2033

Page: 141

High Temperature Composite Resin Market Overview

The High Temperature Composite Resin Market Size is expected to reach USD 4.74 Billion by 2033. The High Temperature Composite Resin industry size accounted for USD 3.56 Billion in 2023 and is expected to expand at a CAGR of 3.96% from 2023 to 2033. High Temperature Composite Resin refers to a specialized type of polymer matrix material designed to maintain its structural integrity and performance properties when exposed to elevated temperatures. Typically used as the matrix component in composite materials, these resins offer exceptional thermal stability, resistance to thermal expansion, and mechanical strength at high temperatures. They are commonly utilized in industries such as aerospace, automotive, and energy, where components are subjected to extreme heat conditions during operation. High Temperature Composite Resins are formulated using thermosetting polymers such as epoxy, phenolic, or bismaleimide (BMI), and they undergo curing processes to achieve their final properties, enabling them to withstand temperatures ranging from several hundred to over a thousand degrees Celsius while retaining their structural integrity.

Global High Temperature Composite Resin Market Synopsis

The High Temperature Composite Resin market experienced a moderate impact during the COVID-19 pandemic, characterized by disruptions in global supply chains, fluctuations in demand from key industries, and delays in project timelines. While the pandemic led to temporary slowdowns in manufacturing activities and project developments, the resilience of end-user industries such as aerospace, automotive, and energy helped mitigate the overall impact on the market. Additionally, the increased focus on lightweight and high-performance materials, coupled with ongoing research and development efforts, positioned the High Temperature Composite Resin market for recovery and future growth post-pandemic.

Global High Temperature Composite Resin Market Dynamics

The major factors that have impacted the growth of High Temperature Composite Resin are as follows:

Drivers:

⮚ Increasing demand for lightweight and high-performance materials in the aerospace and automotive industries

The aerospace and automotive industries are increasingly focusing on reducing weight and improving performance to enhance fuel efficiency, reduce emissions, and meet stringent regulatory standards. High Temperature composite Resins offer a compelling solution, as they provide a combination of lightweight properties, high strength-to-weight ratios, and excellent thermal stability, making them ideal for applications such as aircraft components, automotive engine parts, and structural components in both industries. As a result, the demand for High Temperature Composite Resins is expected to continue growing as manufacturers seek innovative materials to meet evolving industry requirements.

Restraint:

- Cost and complexity of manufacturing processes

While High Temperature Composite Resins offer numerous advantages, including high strength, heat resistance, and corrosion resistance, their manufacturing processes can be complex and costly. Producing High Temperature Composite Resins requires specialized equipment, expertise, and stringent quality control measures to ensure consistency and reliability. The initial investment in manufacturing facilities and the ongoing operational costs can be prohibitive for smaller manufacturers or companies with limited resources, thereby limiting their ability to enter or compete in the High Temperature Composite Resin market. Additionally, the complexity of the manufacturing processes may lead to longer lead times and higher production costs, further hindering market growth.

Opportunity:

⮚ Expansion into emerging industries

High Temperature Composite Resins present significant opportunities for expansion into emerging industries such as renewable energy, transportation, and construction. In the renewable energy sector, High Temperature Composite Resins can be used to manufacture components for wind turbine blades, solar panels, and geothermal systems, where they offer benefits such as durability, corrosion resistance, and thermal stability. In the transportation industry, High Temperature Composite Resins can be utilized in electric vehicles, trains, and ships to reduce weight, improve efficiency, and enhance performance. Moreover, advancements in resin formulations and manufacturing technologies are enabling the development of innovative products with enhanced properties and performance capabilities, opening up new opportunities for market growth and differentiation.

High Temperature Composite Resin Market Segment Overview

By Manufacturing Process

Based on the Manufacturing Process, the market is segmented based on Lay-up, Injection Molding, Compression Molding, Pultrusion, and Others. The Lay-up segment was anticipated to lead the High Temperature Composite Resin market due to its versatility, cost-effectiveness, and suitability for manufacturing complex shapes and large components in aerospace, automotive, and marine industries, where High Temperature resistance and structural integrity are paramount. Additionally, advancements in lay-up techniques and resin formulations contribute to the segment’s dominance by enabling the production of lightweight and high-performance composite structures.

Based on the Manufacturing Process, the market is segmented based on Lay-up, Injection Molding, Compression Molding, Pultrusion, and Others. The Lay-up segment was anticipated to lead the High Temperature Composite Resin market due to its versatility, cost-effectiveness, and suitability for manufacturing complex shapes and large components in aerospace, automotive, and marine industries, where High Temperature resistance and structural integrity are paramount. Additionally, advancements in lay-up techniques and resin formulations contribute to the segment’s dominance by enabling the production of lightweight and high-performance composite structures.

By Type

Based on the Type, the market has been divided into Epoxy, Thermoplastic, Polyimide, Benzoxazine, Bismaleimide, and Others. The Epoxy segment is expected to dominate the High Temperature Composite Resin market, primarily driven by its excellent thermal stability, mechanical strength, and widespread adoption in aerospace, automotive, and electronics industries for applications requiring elevated temperature resistance and durability. Additionally, ongoing research and development efforts aimed at enhancing epoxy resin formulations to meet evolving industry demands further propel its dominance in the market.

By End Use

Based on End Use, the market has been divided into Aerospace & Defense, Automotive & Transportation, Electrical & Electronics, and Others. The Aerospace & Defense segment is positioned to capture the largest market share in the High Temperature Composite Resin market due to increasing demand for lightweight and high-performance materials for aircraft components, engine parts, and structural applications, where High Temperature resistance and mechanical strength are critical requirements. Additionally, stringent regulatory standards and the industry’s emphasis on fuel efficiency and performance drive the adoption of High Temperature Composite Resins in aerospace and defense applications.

Global High Temperature Composite Resin Market Regional Analysis

Based on region, the market has been divided into North America, Europe, Asia-Pacific, the Middle East & Africa, and Latin America. The area of North America is anticipated to dominate the market for the usage of High Temperature Composite Resin, followed by those in Asia-Pacific and Europe.

High Temperature Composite Resin North America Market

North America asserts dominance in the High Temperature Composite Resin market owing to its robust aerospace and defense industries, technological advancements, and extensive research and development efforts. The region’s leading position is further strengthened by a well-established infrastructure, strong regulatory frameworks, and a skilled workforce, facilitating the development and adoption of high-performance composite materials. Additionally, strategic partnerships between key market players and government initiatives supporting innovation and sustainability contribute to North America’s leadership in the global High Temperature Composite Resin market.

High Temperature Composite Resin Asia Pacific Market

The Asia-Pacific region has witnessed remarkable growth in the High Temperature Composite Resin market, fueled by rapid industrialization, infrastructure development, and increasing demand from key sectors such as aerospace, automotive, and electronics. Countries like China, Japan, and South Korea are leading contributors to market growth, driven by their advanced manufacturing capabilities and investments in research and development. Additionally, the region’s burgeoning aerospace and defense industries, coupled with a growing emphasis on lightweight and high-performance materials, further propel the demand for High Temperature Composite Resins. The Asia-Pacific region’s dynamic market landscape and strategic partnerships with global players position it as a key growth engine in the global High Temperature Composite Resin market.

Competitive Landscape

The competitive landscape includes key players (tier 1, tier 2, and local) having a presence across the globe. Companies such as Huntsman International, Hexion, Hexcel Corporation, Royal TenCate, and Sumitomo Bakelite are some of the leading players in the global High Temperature Composite Resin Industry. These players have adopted partnership, acquisition, expansion, and new product development, among others as their key strategies.

Key Market Players:

- Huntsman International

- Hexion

- Hexcel Corporation

- Royal TenCate

- Sumitomo Bakelite

- Arkema

- DIC Corporation

- Lonza

- Nexam Chemical Holding

- UBE Industries

Scope of the Report

Global High Temperature Composite Resin Market, by Manufacturing Process

- Lay-up

- Injection Molding

- Compression Molding

- Pultrusion

- Others

Global High Temperature Composite Resin Market, by Type

- Epoxy

- Thermoplastic

- Polyimide

- Benzoxazine

- Bismaleimide

- Others

Global High Temperature Composite Resin Market, by End Use

- Aerospace & Defense

- Automotive & Transportations

- Electrical & Electronics

- Others

Global High Temperature Composite Resin Market, by Region

- North America

- US

- Canada

- Mexico

- Europe

- UK

- Germany

- France

- Italy

- Spain

- Benelux

- Nordic

- Rest of Europe

- Asia Pacific

- China

- Japan

- South Korea

- Indonesia

- Austalia

- Malaysia

- India

- Rest of Asia Pacific

- South America

- Brazil

- Argentina

- Rest of South America

- Middle East & Africa

- Saudi Arabia

- UAE

- Egypt

- South Africa

- Rest of Middle East & Africa

| Parameters | Indicators |

|---|---|

| Market Size | 2033: $4.74 Billion |

| CAGR | 3.96% CAGR (2023-2033) |

| Base year | 2022 |

| Forecast Period | 2023-2033 |

| Historical Data | 2021 |

| Report Coverage | Revenue Forecast, Competitive Landscape, Growth Factors, and Trends |

| Key Segmentations | Manufacturing Process, Type, End-Use |

| Geographies Covered | North America, Europe, Asia-Pacific, Latin America, Middle East, Africa |

| Key Vendors | Huntsman International, Hexion, Hexcel Corporation, Royal TenCate, Sumitomo Bakelite, Arkema, DIC Corporation, Lonza, Nexam Chemical Holding, UBE Industries |

| Key Market Opportunities | • Expanding applications in emerging industries such as renewable energy, transportation, and construction. • Technological advancements have led to the development of novel resin formulations with enhanced properties and capabilities. |

| Key Market Drivers | • Increasing demand for lightweight and high-performance materials in aerospace, automotive, and electronics industries. • Growing emphasis on sustainability and energy efficiency driving the adoption of composite materials. |

REPORT CONTENT BRIEF:

- High-level analysis of the current and future High Temperature Composite Resin Industry trends and opportunities

- Detailed analysis of current market drivers, restraining factors, and opportunities analysis in the future

- Historical market size for the year 2021, and forecast from 2023 to 2033

- High Temperature Composite Resin market share analysis for each segment

- Competitor analysis with a comprehensive insight into its product segment, financial strength, and strategies adopted.

- Identifies key strategies adopted by the key players including new product development, mergers and acquisitions, joint ventures, collaborations, and partnerships.

- To identify and understand the various factors involved in the global High Temperature Composite Resin market affected by the pandemic

- To provide year-on-year growth from 2022 to 2033

- To provide short-term, long-term, and overall CAGR comparison from 2022 to 2033.

- Provide Total Addressable Market (TAM) for the Global High Temperature Composite Resin Market.

Frequently Asked Questions (FAQ)

What is the study period of the High Temperature Composite Resin Market?

The study period for the High Temperature Composite Resin Market spans from 2021 to the projected years of 2023 to 2033, providing insights into long-term trends and forecasts.

What is the growth rate of the High Temperature Composite Resin Market?

The High Temperature Composite Resin Market is expected to expand at a CAGR of 3.96% from 2023 to 2033, indicating steady growth in the market for specialized polymer matrix materials resistant to elevated temperatures.

Which region has the highest growth rate in the High Temperature Composite Resin Market?

The Asia-Pacific region is poised to experience the highest growth rate in the High Temperature Composite Resin Market, driven by rapid industrialization, infrastructure development, and increasing demand from key sectors such as aerospace, automotive, and electronics.

Which region has the largest share of the High Temperature Composite Resin Market?

North America dominates the High Temperature Composite Resin Market, particularly in the United States and Canada, fueled by robust aerospace and defense industries, technological advancements, and extensive research and development efforts.

Who are the key players in the High Temperature Composite Resin Market?

Key players in the High Temperature Composite Resin Market include Huntsman International, Hexion, Hexcel Corporation, Royal TenCate, Sumitomo Bakelite, Arkema, DIC Corporation, Lonza, Nexam Chemical Holding, and UBE Industries, contributing to a competitive landscape with a focus on innovation and market expansion.

Do you offer Post sales support?

Yes, we offer 16 hours of analyst support to solve the queries

Do you sell particular sections of a report?

Yes, we provide regional as well as country-level reports. Other than this we also provide a sectional report. Please get in contact with our sales representatives.

Table of Content

CHAPTER 1. Executive Summary CHAPTER 2. Scope of the Study 2.1. Market Definition 2.2. Market Scope & Segmentation 2.2.1. Objective of Report CHAPTER 3. Evolve BI Methodology 3.1. Data Collection & Validation Approach 3.2. Market Size Estimation and Forecast CHAPTER 4. Exclusive Analysis 4.1. Market Opportunity Score 4.1.1. Manufacturing Process Segement – Market Opportunity Score 4.1.2. Type Segment – Market Opportunity Score 4.1.3. End Use Segment – Market Opportunity Score 4.2. Key Market Influencing Indicators CHAPTER 5. Market Insights and Trends 5.1. Value Chain Analysis 5.1.1. Raw Material 5.1.2. Manufacturing Process 5.1.3. Distribution Channel 5.1.4. End User 5.2. Porter’s Five Forces Analysis 5.2.1. Bargaining Power of Buyers 5.2.2. Bargaining Power of Suppliers 5.2.3. Threat of New Entrant 5.2.4. Threat of Substitute 5.2.5. Industry Rivalry 5.3. COVID-19 Impact and Post COVID Scenario on High-Temperature Composite Resin Market 5.3.1. Impact of COVID-19 5.3.2. Government Support and Industry Revival Policies 5.3.3. Measures Taken by Companies to Mitigate Negative Impact 5.3.4. Post COVID Trend CHAPTER 6. MArket Dynamics 6.1. Introduction 6.2. Drivers 6.2.1. Driver 1 6.2.2. Driver 2 6.2.3. Driver 3 6.3. Restraints 6.3.1. Restraint 1 6.3.2. Restraint 2 6.4. Opportunity 6.4.1. Opportunity 1 CHAPTER 7. Global High-Temperature Composite Resin Market, By Manufacturing Process 7.1. Introduction 7.1.1. Lay-up 7.1.2. Injection Molding 7.1.3. Compression Molding 7.1.4. Pultrusion 7.1.5. Others CHAPTER 8. Global High-Temperature Composite Resin Market, By Type 8.1. Introduction 8.1.1. Epoxy 8.1.2. Thermoplastic 8.1.3. Polyimide 8.1.4. Benzoxazine 8.1.5. Bismaleimide 8.1.6. Others CHAPTER 9. Global High-Temperature Composite Resin Market, By End Use 9.1. Introduction 9.1.1. Aerospace & Defense 9.1.2. Automotive & Transportations 9.1.3. Electrical & Electronics 9.1.4. Others CHAPTER 10. Global High-Temperature Composite Resin Market, By Region 10.1. Introduction 10.2. NORTH AMERICA 10.2.1. North America: Market Size and Forecast, By Country, 2023 – 2033 ($ Million) 10.2.2. North America: Market Size and Forecast, By Manufacturing Process, 2023 – 2033 ($ Million) 10.2.3. North America: Market Size and Forecast, By Type, 2023 – 2033 ($ Million) 10.2.4. North America: Market Size and Forecast, By End Use, 2023 – 2033 ($ Million) 10.2.5. US 10.2.5.1. US: Market Size and Forecast, By Manufacturing Process, 2023 – 2033 ($ Million) 10.2.5.2. US: Market Size and Forecast, By Type, 2023 – 2033 ($ Million) 10.2.5.3. US: Market Size and Forecast, By End Use, 2023 – 2033 ($ Million) 10.2.6. CANADA 10.2.6.1. Canada: Market Size and Forecast, By Manufacturing Process, 2023 – 2033 ($ Million) 10.2.6.2. Canada: Market Size and Forecast, By Type, 2023 – 2033 ($ Million) 10.2.6.3. Canada: Market Size and Forecast, By End Use, 2023 – 2033 ($ Million) 10.2.7. MEXICO 10.2.7.1. Mexico: Market Size and Forecast, By Manufacturing Process, 2023 – 2033 ($ Million) 10.2.7.2. Mexico: Market Size and Forecast, By Type, 2023 – 2033 ($ Million) 10.2.7.3. Mexico: Market Size and Forecast, By End Use, 2023 – 2033 ($ Million) 10.3. Europe 10.3.1. Europe: Market Size and Forecast, By Country, 2023 – 2033 ($ Million) 10.3.2. Europe: Market Size and Forecast, By Manufacturing Process, 2023 – 2033 ($ Million) 10.3.3. Europe: Market Size and Forecast, By Type, 2023 – 2033 ($ Million) 10.3.4. Europe: Market Size and Forecast, By End Use, 2023 – 2033 ($ Million) 10.3.5. U.K. 10.3.5.1. U.K.: Market Size and Forecast, By Manufacturing Process, 2023 – 2033 ($ Million) 10.3.5.2. U.K.: Market Size and Forecast, By Type, 2023 – 2033 ($ Million) 10.3.5.3. U.K.: Market Size and Forecast, By End Use, 2023 – 2033 ($ Million) 10.3.6. GERMANY 10.3.6.1. Germany: Market Size and Forecast, By Manufacturing Process, 2023 – 2033 ($ Million) 10.3.6.2. Germany: Market Size and Forecast, By Type, 2023 – 2033 ($ Million) 10.3.6.3. Germany: Market Size and Forecast, By End Use, 2023 – 2033 ($ Million) 10.3.7. FRANCE 10.3.7.1. France: Market Size and Forecast, By Manufacturing Process, 2023 – 2033 ($ Million) 10.3.7.2. France: Market Size and Forecast, By Type, 2023 – 2033 ($ Million) 10.3.7.3. France: Market Size and Forecast, By End Use, 2023 – 2033 ($ Million) 10.3.8. ITALY 10.3.8.1. Italy: Market Size and Forecast, By Manufacturing Process, 2023 – 2033 ($ Million) 10.3.8.2. Italy: Market Size and Forecast, By Type, 2023 – 2033 ($ Million) 10.3.8.3. Italy: Market Size and Forecast, By End Use, 2023 – 2033 ($ Million) 10.3.9. SPAIN 10.3.9.1. Spain: Market Size and Forecast, By Manufacturing Process, 2023 – 2033 ($ Million) 10.3.9.2. Spain: Market Size and Forecast, By Type, 2023 – 2033 ($ Million) 10.3.9.3. Spain: Market Size and Forecast, By End Use, 2023 – 2033 ($ Million) 10.3.10. BENELUX 10.3.10.1. BeNeLux: Market Size and Forecast, By Manufacturing Process, 2023 – 2033 ($ Million) 10.3.10.2. BeNeLux: Market Size and Forecast, By Type, 2023 – 2033 ($ Million) 10.3.10.3. BeNeLux: Market Size and Forecast, By End Use, 2023 – 2033 ($ Million) 10.3.11. RUSSIA 10.3.11.1. Russia: Market Size and Forecast, By Manufacturing Process, 2023 – 2033 ($ Million) 10.3.11.2. Russia: Market Size and Forecast, By Type, 2023 – 2033 ($ Million) 10.3.11.3. Russia: Market Size and Forecast, By End Use, 2023 – 2033 ($ Million) 10.3.12. REST OF EUROPE 10.3.12.1. Rest of Europe: Market Size and Forecast, By Manufacturing Process, 2023 – 2033 ($ Million) 10.3.12.2. Rest of Europe: Market Size and Forecast, By Type, 2023 – 2033 ($ Million) 10.3.12.3. Rest of Europe: Market Size and Forecast, By End Use, 2023 – 2033 ($ Million) 10.4. Asia Pacific 10.4.1. Asia Pacific: Market Size and Forecast, By Country, 2023 – 2033 ($ Million) 10.4.2. Asia Pacific: Market Size and Forecast, By Manufacturing Process, 2023 – 2033 ($ Million) 10.4.3. Asia Pacific: Market Size and Forecast, By Type, 2023 – 2033 ($ Million) 10.4.4. Asia Pacific: Market Size and Forecast, By End Use, 2023 – 2033 ($ Million) 10.4.5. CHINA 10.4.5.1. China: Market Size and Forecast, By Manufacturing Process, 2023 – 2033 ($ Million) 10.4.5.2. China: Market Size and Forecast, By Type, 2023 – 2033 ($ Million) 10.4.5.3. China: Market Size and Forecast, By End Use, 2023 – 2033 ($ Million) 10.4.6. JAPAN 10.4.6.1. Japan: Market Size and Forecast, By Manufacturing Process, 2023 – 2033 ($ Million) 10.4.6.2. Japan: Market Size and Forecast, By Type, 2023 – 2033 ($ Million) 10.4.6.3. Japan: Market Size and Forecast, By End Use, 2023 – 2033 ($ Million) 10.4.7. INDIA 10.4.7.1. India: Market Size and Forecast, By Manufacturing Process, 2023 – 2033 ($ Million) 10.4.7.2. India: Market Size and Forecast, By Type, 2023 – 2033 ($ Million) 10.4.7.3. India: Market Size and Forecast, By End Use, 2023 – 2033 ($ Million) 10.4.8. SOUTH KOREA 10.4.8.1. South Korea: Market Size and Forecast, By Manufacturing Process, 2023 – 2033 ($ Million) 10.4.8.2. South Korea: Market Size and Forecast, By Type, 2023 – 2033 ($ Million) 10.4.8.3. South Korea: Market Size and Forecast, By End Use, 2023 – 2033 ($ Million) 10.4.9. THAILAND 10.4.9.1. Thailand: Market Size and Forecast, By Manufacturing Process, 2023 – 2033 ($ Million) 10.4.9.2. Thailand: Market Size and Forecast, By Type, 2023 – 2033 ($ Million) 10.4.9.3. Thailand: Market Size and Forecast, By End Use, 2023 – 2033 ($ Million) 10.4.10. INDONESIA 10.4.10.1. Indonesia: Market Size and Forecast, By Manufacturing Process, 2023 – 2033 ($ Million) 10.4.10.2. Indonesia: Market Size and Forecast, By Type, 2023 – 2033 ($ Million) 10.4.10.3. Indonesia: Market Size and Forecast, By End Use, 2023 – 2033 ($ Million) 10.4.11. MALAYSIA 10.4.11.1. Malaysia: Market Size and Forecast, By Manufacturing Process, 2023 – 2033 ($ Million) 10.4.11.2. Malaysia: Market Size and Forecast, By Type, 2023 – 2033 ($ Million) 10.4.11.3. Malaysia: Market Size and Forecast, By End Use, 2023 – 2033 ($ Million) 10.4.12. AUSTRALIA 10.4.12.1. Australia: Market Size and Forecast, By Manufacturing Process, 2023 – 2033 ($ Million) 10.4.12.2. Australia: Market Size and Forecast, By Type, 2023 – 2033 ($ Million) 10.4.12.3. Australia: Market Size and Forecast, By End Use, 2023 – 2033 ($ Million) 10.4.13. REST FO ASIA PACIFIC 10.4.13.1. Rest fo Asia Pacific: Market Size and Forecast, By Manufacturing Process, 2023 – 2033 ($ Million) 10.4.13.2. Rest fo Asia Pacific: Market Size and Forecast, By Type, 2023 – 2033 ($ Million) 10.4.13.3. Rest fo Asia Pacific: Market Size and Forecast, By End Use, 2023 – 2033 ($ Million) 10.5. South America 10.5.1. South America: Market Size and Forecast, By Country, 2023 – 2033 ($ Million) 10.5.2. South America: Market Size and Forecast, By Manufacturing Process, 2023 – 2033 ($ Million) 10.5.3. South America: Market Size and Forecast, By Type, 2023 – 2033 ($ Million) 10.5.4. South America: Market Size and Forecast, By End Use, 2023 – 2033 ($ Million) 10.5.5. BRAZIL 10.5.5.1. Brazil: Market Size and Forecast, By Manufacturing Process, 2023 – 2033 ($ Million) 10.5.5.2. Brazil: Market Size and Forecast, By Type, 2023 – 2033 ($ Million) 10.5.5.3. Brazil: Market Size and Forecast, By End Use, 2023 – 2033 ($ Million) 10.5.6. ARGENTINA 10.5.6.1. Argentina: Market Size and Forecast, By Manufacturing Process, 2023 – 2033 ($ Million) 10.5.6.2. Argentina: Market Size and Forecast, By Type, 2023 – 2033 ($ Million) 10.5.6.3. Argentina: Market Size and Forecast, By End Use, 2023 – 2033 ($ Million) 10.5.7. REST OF SOUTH AMERICA 10.5.7.1. Rest of South America: Market Size and Forecast, By Manufacturing Process, 2023 – 2033 ($ Million) 10.5.7.2. Rest of South America: Market Size and Forecast, By Type, 2023 – 2033 ($ Million) 10.5.7.3. Rest of South America: Market Size and Forecast, By End Use, 2023 – 2033 ($ Million) 10.6. Middle East & Africa 10.6.1. Middle East & Africa: Market Size and Forecast, By Country, 2023 – 2033 ($ Million) 10.6.2. Middle East & Africa: Market Size and Forecast, By Manufacturing Process, 2023 – 2033 ($ Million) 10.6.3. Middle East & Africa: Market Size and Forecast, By Type, 2023 – 2033 ($ Million) 10.6.4. Middle East & Africa: Market Size and Forecast, By End Use, 2023 – 2033 ($ Million) 10.6.5. SAUDI ARABIA 10.6.5.1. Saudi Arabia: Market Size and Forecast, By Manufacturing Process, 2023 – 2033 ($ Million) 10.6.5.2. Saudi Arabia: Market Size and Forecast, By Type, 2023 – 2033 ($ Million) 10.6.5.3. Saudi Arabia: Market Size and Forecast, By End Use, 2023 – 2033 ($ Million) 10.6.6. UAE 10.6.6.1. UAE: Market Size and Forecast, By Manufacturing Process, 2023 – 2033 ($ Million) 10.6.6.2. UAE: Market Size and Forecast, By Type, 2023 – 2033 ($ Million) 10.6.6.3. UAE: Market Size and Forecast, By End Use, 2023 – 2033 ($ Million) 10.6.7. EGYPT 10.6.7.1. Egypt: Market Size and Forecast, By Manufacturing Process, 2023 – 2033 ($ Million) 10.6.7.2. Egypt: Market Size and Forecast, By Type, 2023 – 2033 ($ Million) 10.6.7.3. Egypt: Market Size and Forecast, By End Use, 2023 – 2033 ($ Million) 10.6.8. SOUTH AFRICA 10.6.8.1. South Africa: Market Size and Forecast, By Manufacturing Process, 2023 – 2033 ($ Million) 10.6.8.2. South Africa: Market Size and Forecast, By Type, 2023 – 2033 ($ Million) 10.6.8.3. South Africa: Market Size and Forecast, By End Use, 2023 – 2033 ($ Million) 10.6.9. REST OF MIDDLE EAST & AFRICA 10.6.9.1. Rest of Middle East & Africa: Market Size and Forecast, By Manufacturing Process, 2023 – 2033 ($ Million) 10.6.9.2. Rest of Middle East & Africa: Market Size and Forecast, By Type, 2023 – 2033 ($ Million) 10.6.9.3. Rest of Middle East & Africa: Market Size and Forecast, By End Use, 2023 – 2033 ($ Million) CHAPTER 12. Competitive Landscape 12.1. Competitior Benchmarking 2023 12.2. Market Share Analysis 12.3. Key Developments Analysis By Top 5 Companies 12.4. Market Share Acquisition Strategies: Analysis of Key Approaches Employed by Top Players CHAPTER 13. Company Profiles 13.1. Huntsman International 13.1.1. Business Overview 13.1.2. Financial Analysis 13.1.2.1. Business Segment Revenue, 2020, 2021, 2022, $ Million 13.1.2.2. Geographic Revenue Mix, 2022 (% Share) 13.1.3. Product Portfolio 13.1.4. Recent Development and Strategies Adopted 13.1.5. SWOT Analysis 13.2. Hexion 13.3. Hexcel Corporation 13.4. Royal TenCate 13.5. Sumitomo Bakelite 13.6. Arkema 13.7. DIC Corporation 13.8. Lonza 13.9. Nexam Chemical Holding 13.10. UBE Industries

Connect to Analyst

Research Methodology

CHAPTER 1. Executive Summary

CHAPTER 2. Scope of the Study

2.1. Market Definition

2.2. Market Scope & Segmentation

2.2.1. Objective of Report

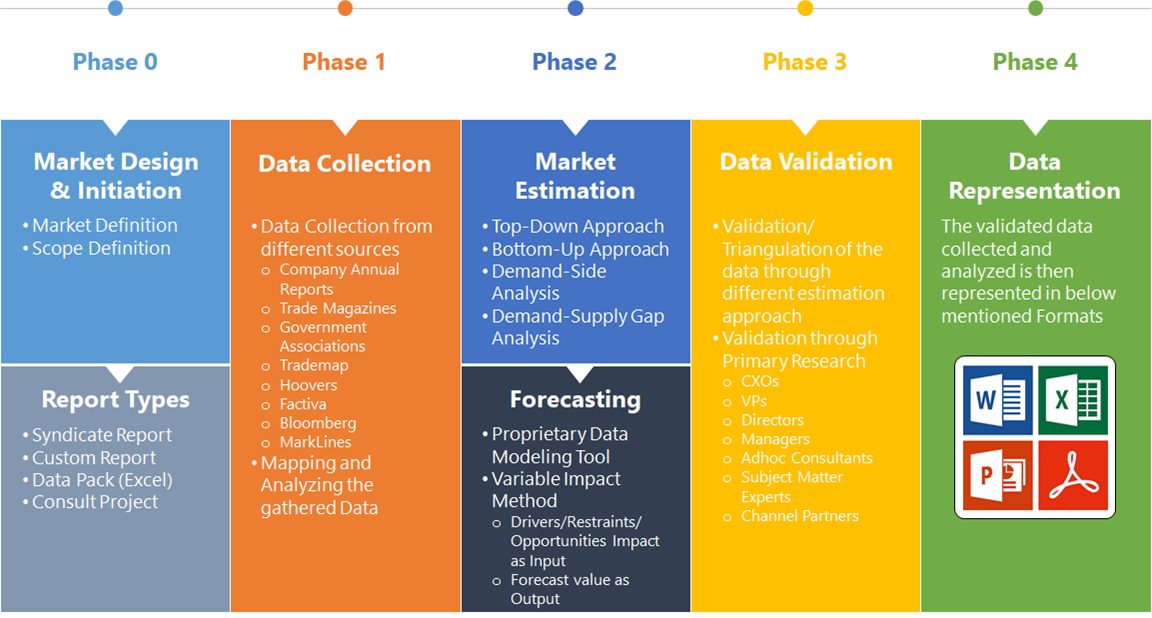

CHAPTER 3. Evolve BI Methodology

3.1. Data Collection & Validation Approach

3.2. Market Size Estimation and Forecast

CHAPTER 4. Exclusive Analysis

4.1. Market Opportunity Score

4.1.1. Manufacturing Process Segement – Market Opportunity Score

4.1.2. Type Segment – Market Opportunity Score

4.1.3. End Use Segment – Market Opportunity Score

4.2. Key Market Influencing Indicators

CHAPTER 5. Market Insights and Trends

5.1. Value Chain Analysis

5.1.1. Raw Material

5.1.2. Manufacturing Process

5.1.3. Distribution Channel

5.1.4. End User

5.2. Porter’s Five Forces Analysis

5.2.1. Bargaining Power of Buyers

5.2.2. Bargaining Power of Suppliers

5.2.3. Threat of New Entrant

5.2.4. Threat of Substitute

5.2.5. Industry Rivalry

5.3. COVID-19 Impact and Post COVID Scenario on High-Temperature Composite Resin Market

5.3.1. Impact of COVID-19

5.3.2. Government Support and Industry Revival Policies

5.3.3. Measures Taken by Companies to Mitigate Negative Impact

5.3.4. Post COVID Trend

CHAPTER 6. MArket Dynamics

6.1. Introduction

6.2. Drivers

6.2.1. Driver 1

6.2.2. Driver 2

6.2.3. Driver 3

6.3. Restraints

6.3.1. Restraint 1

6.3.2. Restraint 2

6.4. Opportunity

6.4.1. Opportunity 1

CHAPTER 7. Global High-Temperature Composite Resin Market, By Manufacturing Process

7.1. Introduction

7.1.1. Lay-up

7.1.2. Injection Molding

7.1.3. Compression Molding

7.1.4. Pultrusion

7.1.5. Others

CHAPTER 8. Global High-Temperature Composite Resin Market, By Type

8.1. Introduction

8.1.1. Epoxy

8.1.2. Thermoplastic

8.1.3. Polyimide

8.1.4. Benzoxazine

8.1.5. Bismaleimide

8.1.6. Others

CHAPTER 9. Global High-Temperature Composite Resin Market, By End Use

9.1. Introduction

9.1.1. Aerospace & Defense

9.1.2. Automotive & Transportations

9.1.3. Electrical & Electronics

9.1.4. Others

CHAPTER 10. Global High-Temperature Composite Resin Market, By Region

10.1. Introduction

10.2. NORTH AMERICA

10.2.1. North America: Market Size and Forecast, By Country, 2023 – 2033 ($ Million)

10.2.2. North America: Market Size and Forecast, By Manufacturing Process, 2023 – 2033 ($ Million)

10.2.3. North America: Market Size and Forecast, By Type, 2023 – 2033 ($ Million)

10.2.4. North America: Market Size and Forecast, By End Use, 2023 – 2033 ($ Million)

10.2.5. US

10.2.5.1. US: Market Size and Forecast, By Manufacturing Process, 2023 – 2033 ($ Million)

10.2.5.2. US: Market Size and Forecast, By Type, 2023 – 2033 ($ Million)

10.2.5.3. US: Market Size and Forecast, By End Use, 2023 – 2033 ($ Million)

10.2.6. CANADA

10.2.6.1. Canada: Market Size and Forecast, By Manufacturing Process, 2023 – 2033 ($ Million)

10.2.6.2. Canada: Market Size and Forecast, By Type, 2023 – 2033 ($ Million)

10.2.6.3. Canada: Market Size and Forecast, By End Use, 2023 – 2033 ($ Million)

10.2.7. MEXICO

10.2.7.1. Mexico: Market Size and Forecast, By Manufacturing Process, 2023 – 2033 ($ Million)

10.2.7.2. Mexico: Market Size and Forecast, By Type, 2023 – 2033 ($ Million)

10.2.7.3. Mexico: Market Size and Forecast, By End Use, 2023 – 2033 ($ Million)

10.3. Europe

10.3.1. Europe: Market Size and Forecast, By Country, 2023 – 2033 ($ Million)

10.3.2. Europe: Market Size and Forecast, By Manufacturing Process, 2023 – 2033 ($ Million)

10.3.3. Europe: Market Size and Forecast, By Type, 2023 – 2033 ($ Million)

10.3.4. Europe: Market Size and Forecast, By End Use, 2023 – 2033 ($ Million)

10.3.5. U.K.

10.3.5.1. U.K.: Market Size and Forecast, By Manufacturing Process, 2023 – 2033 ($ Million)

10.3.5.2. U.K.: Market Size and Forecast, By Type, 2023 – 2033 ($ Million)

10.3.5.3. U.K.: Market Size and Forecast, By End Use, 2023 – 2033 ($ Million)

10.3.6. GERMANY

10.3.6.1. Germany: Market Size and Forecast, By Manufacturing Process, 2023 – 2033 ($ Million)

10.3.6.2. Germany: Market Size and Forecast, By Type, 2023 – 2033 ($ Million)

10.3.6.3. Germany: Market Size and Forecast, By End Use, 2023 – 2033 ($ Million)

10.3.7. FRANCE

10.3.7.1. France: Market Size and Forecast, By Manufacturing Process, 2023 – 2033 ($ Million)

10.3.7.2. France: Market Size and Forecast, By Type, 2023 – 2033 ($ Million)

10.3.7.3. France: Market Size and Forecast, By End Use, 2023 – 2033 ($ Million)

10.3.8. ITALY

10.3.8.1. Italy: Market Size and Forecast, By Manufacturing Process, 2023 – 2033 ($ Million)

10.3.8.2. Italy: Market Size and Forecast, By Type, 2023 – 2033 ($ Million)

10.3.8.3. Italy: Market Size and Forecast, By End Use, 2023 – 2033 ($ Million)

10.3.9. SPAIN

10.3.9.1. Spain: Market Size and Forecast, By Manufacturing Process, 2023 – 2033 ($ Million)

10.3.9.2. Spain: Market Size and Forecast, By Type, 2023 – 2033 ($ Million)

10.3.9.3. Spain: Market Size and Forecast, By End Use, 2023 – 2033 ($ Million)

10.3.10. BENELUX

10.3.10.1. BeNeLux: Market Size and Forecast, By Manufacturing Process, 2023 – 2033 ($ Million)

10.3.10.2. BeNeLux: Market Size and Forecast, By Type, 2023 – 2033 ($ Million)

10.3.10.3. BeNeLux: Market Size and Forecast, By End Use, 2023 – 2033 ($ Million)

10.3.11. RUSSIA

10.3.11.1. Russia: Market Size and Forecast, By Manufacturing Process, 2023 – 2033 ($ Million)

10.3.11.2. Russia: Market Size and Forecast, By Type, 2023 – 2033 ($ Million)

10.3.11.3. Russia: Market Size and Forecast, By End Use, 2023 – 2033 ($ Million)

10.3.12. REST OF EUROPE

10.3.12.1. Rest of Europe: Market Size and Forecast, By Manufacturing Process, 2023 – 2033 ($ Million)

10.3.12.2. Rest of Europe: Market Size and Forecast, By Type, 2023 – 2033 ($ Million)

10.3.12.3. Rest of Europe: Market Size and Forecast, By End Use, 2023 – 2033 ($ Million)

10.4. Asia Pacific

10.4.1. Asia Pacific: Market Size and Forecast, By Country, 2023 – 2033 ($ Million)

10.4.2. Asia Pacific: Market Size and Forecast, By Manufacturing Process, 2023 – 2033 ($ Million)

10.4.3. Asia Pacific: Market Size and Forecast, By Type, 2023 – 2033 ($ Million)

10.4.4. Asia Pacific: Market Size and Forecast, By End Use, 2023 – 2033 ($ Million)

10.4.5. CHINA

10.4.5.1. China: Market Size and Forecast, By Manufacturing Process, 2023 – 2033 ($ Million)

10.4.5.2. China: Market Size and Forecast, By Type, 2023 – 2033 ($ Million)

10.4.5.3. China: Market Size and Forecast, By End Use, 2023 – 2033 ($ Million)

10.4.6. JAPAN

10.4.6.1. Japan: Market Size and Forecast, By Manufacturing Process, 2023 – 2033 ($ Million)

10.4.6.2. Japan: Market Size and Forecast, By Type, 2023 – 2033 ($ Million)

10.4.6.3. Japan: Market Size and Forecast, By End Use, 2023 – 2033 ($ Million)

10.4.7. INDIA

10.4.7.1. India: Market Size and Forecast, By Manufacturing Process, 2023 – 2033 ($ Million)

10.4.7.2. India: Market Size and Forecast, By Type, 2023 – 2033 ($ Million)

10.4.7.3. India: Market Size and Forecast, By End Use, 2023 – 2033 ($ Million)

10.4.8. SOUTH KOREA

10.4.8.1. South Korea: Market Size and Forecast, By Manufacturing Process, 2023 – 2033 ($ Million)

10.4.8.2. South Korea: Market Size and Forecast, By Type, 2023 – 2033 ($ Million)

10.4.8.3. South Korea: Market Size and Forecast, By End Use, 2023 – 2033 ($ Million)

10.4.9. THAILAND

10.4.9.1. Thailand: Market Size and Forecast, By Manufacturing Process, 2023 – 2033 ($ Million)

10.4.9.2. Thailand: Market Size and Forecast, By Type, 2023 – 2033 ($ Million)

10.4.9.3. Thailand: Market Size and Forecast, By End Use, 2023 – 2033 ($ Million)

10.4.10. INDONESIA

10.4.10.1. Indonesia: Market Size and Forecast, By Manufacturing Process, 2023 – 2033 ($ Million)

10.4.10.2. Indonesia: Market Size and Forecast, By Type, 2023 – 2033 ($ Million)

10.4.10.3. Indonesia: Market Size and Forecast, By End Use, 2023 – 2033 ($ Million)

10.4.11. MALAYSIA

10.4.11.1. Malaysia: Market Size and Forecast, By Manufacturing Process, 2023 – 2033 ($ Million)

10.4.11.2. Malaysia: Market Size and Forecast, By Type, 2023 – 2033 ($ Million)

10.4.11.3. Malaysia: Market Size and Forecast, By End Use, 2023 – 2033 ($ Million)

10.4.12. AUSTRALIA

10.4.12.1. Australia: Market Size and Forecast, By Manufacturing Process, 2023 – 2033 ($ Million)

10.4.12.2. Australia: Market Size and Forecast, By Type, 2023 – 2033 ($ Million)

10.4.12.3. Australia: Market Size and Forecast, By End Use, 2023 – 2033 ($ Million)

10.4.13. REST FO ASIA PACIFIC

10.4.13.1. Rest fo Asia Pacific: Market Size and Forecast, By Manufacturing Process, 2023 – 2033 ($ Million)

10.4.13.2. Rest fo Asia Pacific: Market Size and Forecast, By Type, 2023 – 2033 ($ Million)

10.4.13.3. Rest fo Asia Pacific: Market Size and Forecast, By End Use, 2023 – 2033 ($ Million)

10.5. South America

10.5.1. South America: Market Size and Forecast, By Country, 2023 – 2033 ($ Million)

10.5.2. South America: Market Size and Forecast, By Manufacturing Process, 2023 – 2033 ($ Million)

10.5.3. South America: Market Size and Forecast, By Type, 2023 – 2033 ($ Million)

10.5.4. South America: Market Size and Forecast, By End Use, 2023 – 2033 ($ Million)

10.5.5. BRAZIL

10.5.5.1. Brazil: Market Size and Forecast, By Manufacturing Process, 2023 – 2033 ($ Million)

10.5.5.2. Brazil: Market Size and Forecast, By Type, 2023 – 2033 ($ Million)

10.5.5.3. Brazil: Market Size and Forecast, By End Use, 2023 – 2033 ($ Million)

10.5.6. ARGENTINA

10.5.6.1. Argentina: Market Size and Forecast, By Manufacturing Process, 2023 – 2033 ($ Million)

10.5.6.2. Argentina: Market Size and Forecast, By Type, 2023 – 2033 ($ Million)

10.5.6.3. Argentina: Market Size and Forecast, By End Use, 2023 – 2033 ($ Million)

10.5.7. REST OF SOUTH AMERICA

10.5.7.1. Rest of South America: Market Size and Forecast, By Manufacturing Process, 2023 – 2033 ($ Million)

10.5.7.2. Rest of South America: Market Size and Forecast, By Type, 2023 – 2033 ($ Million)

10.5.7.3. Rest of South America: Market Size and Forecast, By End Use, 2023 – 2033 ($ Million)

10.6. Middle East & Africa

10.6.1. Middle East & Africa: Market Size and Forecast, By Country, 2023 – 2033 ($ Million)

10.6.2. Middle East & Africa: Market Size and Forecast, By Manufacturing Process, 2023 – 2033 ($ Million)

10.6.3. Middle East & Africa: Market Size and Forecast, By Type, 2023 – 2033 ($ Million)

10.6.4. Middle East & Africa: Market Size and Forecast, By End Use, 2023 – 2033 ($ Million)

10.6.5. SAUDI ARABIA

10.6.5.1. Saudi Arabia: Market Size and Forecast, By Manufacturing Process, 2023 – 2033 ($ Million)

10.6.5.2. Saudi Arabia: Market Size and Forecast, By Type, 2023 – 2033 ($ Million)

10.6.5.3. Saudi Arabia: Market Size and Forecast, By End Use, 2023 – 2033 ($ Million)

10.6.6. UAE

10.6.6.1. UAE: Market Size and Forecast, By Manufacturing Process, 2023 – 2033 ($ Million)

10.6.6.2. UAE: Market Size and Forecast, By Type, 2023 – 2033 ($ Million)

10.6.6.3. UAE: Market Size and Forecast, By End Use, 2023 – 2033 ($ Million)

10.6.7. EGYPT

10.6.7.1. Egypt: Market Size and Forecast, By Manufacturing Process, 2023 – 2033 ($ Million)

10.6.7.2. Egypt: Market Size and Forecast, By Type, 2023 – 2033 ($ Million)

10.6.7.3. Egypt: Market Size and Forecast, By End Use, 2023 – 2033 ($ Million)

10.6.8. SOUTH AFRICA

10.6.8.1. South Africa: Market Size and Forecast, By Manufacturing Process, 2023 – 2033 ($ Million)

10.6.8.2. South Africa: Market Size and Forecast, By Type, 2023 – 2033 ($ Million)

10.6.8.3. South Africa: Market Size and Forecast, By End Use, 2023 – 2033 ($ Million)

10.6.9. REST OF MIDDLE EAST & AFRICA

10.6.9.1. Rest of Middle East & Africa: Market Size and Forecast, By Manufacturing Process, 2023 – 2033 ($ Million)

10.6.9.2. Rest of Middle East & Africa: Market Size and Forecast, By Type, 2023 – 2033 ($ Million)

10.6.9.3. Rest of Middle East & Africa: Market Size and Forecast, By End Use, 2023 – 2033 ($ Million)

CHAPTER 12. Competitive Landscape

12.1. Competitior Benchmarking 2023

12.2. Market Share Analysis

12.3. Key Developments Analysis By Top 5 Companies

12.4. Market Share Acquisition Strategies: Analysis of Key Approaches Employed by Top Players

CHAPTER 13. Company Profiles

13.1. Huntsman International

13.1.1. Business Overview

13.1.2. Financial Analysis

13.1.2.1. Business Segment Revenue, 2020, 2021, 2022, $ Million

13.1.2.2. Geographic Revenue Mix, 2022 (% Share)

13.1.3. Product Portfolio

13.1.4. Recent Development and Strategies Adopted

13.1.5. SWOT Analysis

13.2. Hexion

13.3. Hexcel Corporation

13.4. Royal TenCate

13.5. Sumitomo Bakelite

13.6. Arkema

13.7. DIC Corporation

13.8. Lonza

13.9. Nexam Chemical Holding

13.10. UBE Industries