FRP Vessels Market Analysis and Global Forecast 2023-2033

$ 1,390.00 – $ 5,520.00Price range: $ 1,390.00 through $ 5,520.00

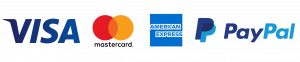

FRP Vessels Market Research Report: Information By Fiber (Glass, Carbon, Others), By Resin (Polyester, Epoxy, Others), By Application (Automotive & Transportation, Chemicals, Industrial, Oil & Gas, Water & Wastewater, Others), and by Region — Forecast till 2033

Page: 170

FRP Vessels Market Overview

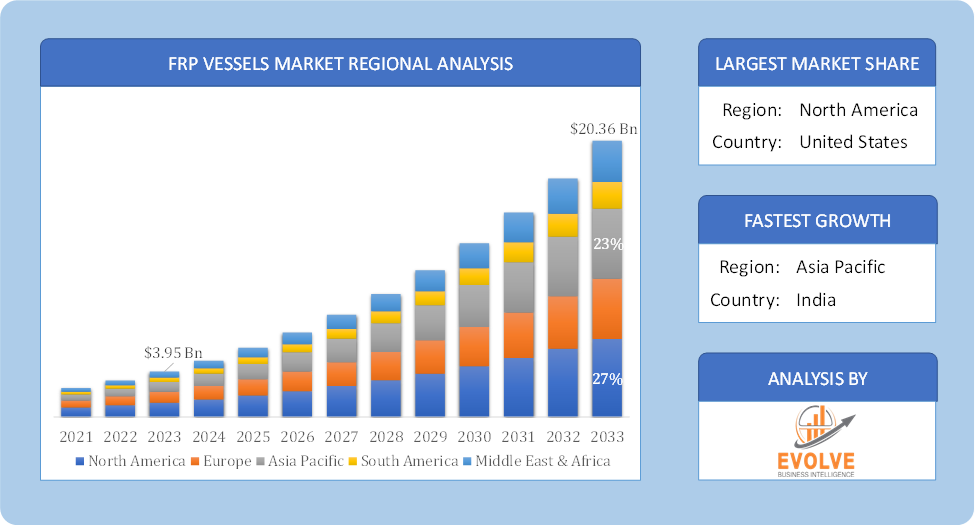

The FRP Vessels Market Size is expected to reach USD 20.36 Billion by 2033. The FRP Vessels Market industry size accounted for USD 3.95 Billion in 2023 and is expected to expand at a compound annual growth rate (CAGR) of 10.52% from 2023 to 2033. The FRP (Fiber Reinforced Plastic) Vessels Market refers to the industry involved in manufacturing and supplying vessels or tanks made from composite materials such as fiberglass reinforced with plastics. These vessels are used across various industries for storing corrosive chemicals, water, and other liquids due to their corrosion resistance, lightweight nature, and durability. The market encompasses manufacturers, suppliers, and distributors of FRP vessels, catering to sectors like water treatment, chemical processing, oil and gas, and food processing industries.

The FRP vessel market is expected to grow at a significant rate in the coming years, driven by factors such as increasing demand for water and wastewater treatment, rising investments in the chemical and oil & gas industries, and growing awareness of the benefits of FRP vessels over traditional materials such as steel and concrete.

Global FRP Vessels Market Synopsis

COVID-19 Impact Analysis

COVID-19 Impact Analysis

The COVID-19 pandemic had significant impacts on the FRP Vessels Market. Lockdowns and restrictions disrupted supply chains globally, affecting the availability of raw materials and components necessary for manufacturing FRP vessels. Many industries that use FRP vessels, such as oil and gas, chemical processing, and water treatment, experienced reduced demand due to economic slowdowns and temporary shutdowns of operations. Restrictions on movement and safety protocols led to labor shortages, affecting production capabilities in some regions. Construction and infrastructure projects that would have required FRP vessels were delayed or put on hold, impacting market growth. Economic uncertainty and reduced investments affected capital expenditure budgets, impacting the purchase of new FRP vessels.

FRP Vessels Market Dynamics

The major factors that have impacted the growth of FRP Vessels Market are as follows:

Drivers:

Ø Corrosion Resistance

FRP vessels are highly resistant to corrosion, making them suitable for storing corrosive chemicals and liquids in industries such as chemical processing, water treatment, and oil and gas. FRP vessels often have lower lifecycle costs compared to alternatives due to their longevity, reduced maintenance requirements, and lower installation costs. Compared to traditional materials like steel, FRP vessels are lightweight yet durable, offering ease of installation, transportation, and maintenance. FRP can be molded into various shapes and sizes, providing flexibility in design and customization according to specific industry needs and space constraints. Innovations in composite materials and manufacturing processes improve the performance, reliability, and cost-effectiveness of FRP vessels, enhancing their appeal in various applications.

Restraint:

- Perception of Initial Cost and Quality Concerns

Despite their long-term cost-effectiveness, FRP vessels can have a higher initial cost compared to traditional materials like steel. This upfront investment may deter potential buyers who prioritize immediate cost savings over long-term benefits. There may be concerns about the quality and reliability of FRP vessels, especially if they are not manufactured to stringent standards or if there are issues with resin quality, curing processes, or structural integrity. Such concerns can affect trust and adoption among potential customers.

Opportunity:

⮚ Growing Demand in Water Treatment

Increasing global focus on water conservation and wastewater treatment drives the demand for durable and corrosion-resistant storage solutions like FRP vessels. The chemical processing industry continues to adopt FRP vessels due to their resistance to corrosion from chemicals, acids, and bases, presenting significant market opportunities. As renewable energy sectors expand, such as solar and wind power, there is a need for storage solutions that can withstand environmental elements and harsh conditions, where FRP vessels can play a role. Ongoing research and development in composite materials technology can lead to lighter, stronger, and more cost-effective FRP vessels, enhancing their attractiveness across various industries.

FRP Vessels Market Segment Overview

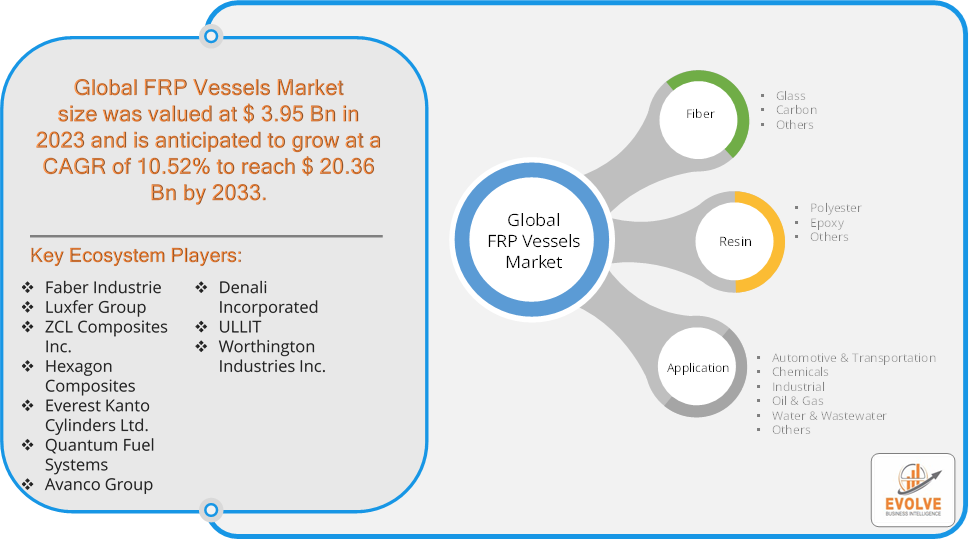

By Fiber

By Fiber

Based on Fiber, the market is segmented based on Glass, Carbon and Others. Glass fibers segment dominant the market. FRP vessel composed of glass fiber is also known as a glass-reinforced plastic vessel (GRP). Glass-reinforced plastic (GRP) is a plastic composite material incorporating glass fiber to increase strength and rigidity. It is commonly employed in fabricating vessels utilized in chemical and wastewater treatment plants. This fiber provides corrosion resistance and tensile solid and hydrostatic strength in an FRP vessel.

By Resin

Based on Resin, the market segment has been divided into Polyester, Epoxy and Others. Polyester-resin-fabricated FRP containers offer adaptability, dimensional stability, mechanical properties, and chemical resistance, among other advantages. Due to mechanical impacts, salt, starch, dairy residues, and other harsh environmental conditions, hygienic walls and ceilings in the food sector are typically vulnerable to wear and tear. Thus, sheets and panels made of fiberglass-reinforced polyester are commonly used in the food business to construct walls.

By Application

Based on Application, the market segment has been divided into Automotive & Transportation, Chemicals, Industrial, Oil & Gas, Water & Wastewater and Others. The automotive & transportation segment dominant the market, FRPs is known as precious metal alternatives mainly in the frames of lavish automobiles and also in trailer body sidings. In addition, rapid growth in the number of automobiles sales especially electric vehicles across the globe, that results in higher integration of FRP vessels into automotive sector and furling the segment market exponentially.

Global FRP Vessels Market Regional Analysis

Based on region, the global FRP Vessels Market has been divided into North America, Europe, Asia-Pacific, the Middle East & Africa, and Latin America. North America is projected to dominate the use of the FRP Vessels Market followed by the Asia-Pacific and Europe regions.

FRP Vessels North America Market

FRP Vessels North America Market

North America holds a dominant position in the FRP Vessels Market. The U.S. has a significant chemical manufacturing sector, which drives the demand for FRP vessels due to their corrosion resistance and durability. The Gulf Coast region, particularly Texas and Louisiana, is a major hub for chemical and petrochemical industries, boosting the market for FRP vessels. Similar to the U.S., Canada has a strong presence in the chemical and petrochemical sectors, particularly in Alberta. The demand for corrosion-resistant storage solutions like FRP vessels is strong in these regions.

FRP Vessels Asia-Pacific Market

The Asia-Pacific region has indeed emerged as the fastest-growing market for the FRP Vessels Market industry. China’s rapid industrialization, particularly in the chemical, oil and gas, and water treatment sectors, fuels the demand for FRP vessels. The country’s focus on expanding its industrial capacity supports the widespread use of FRP vessels for their corrosion resistance and durability. Also, India’s growing population and urbanization necessitate investments in water and wastewater treatment facilities, leading to increased demand for FRP vessels that can withstand corrosive environments and provide long-lasting performance.

Competitive Landscape

The global FRP Vessels Market is highly competitive, with numerous players offering a wide range of software solutions. The competitive landscape is characterized by the presence of established companies, as well as emerging startups and niche players. To increase their market position and attract a wide consumer base, the businesses are employing various strategies, such as product launches, and strategic alliances.

Prominent Players:

- Faber Industrie

- Luxfer Group

- ZCL Composites Inc.

- Hexagon Composites

- Everest Kanto Cylinders Ltd.

- Quantum Fuel Systems

- Avanco Group

- Denali Incorporated

- ULLIT

- Worthington Industries Inc.

Key Development

In July 2022, Rev1 Ventures entered into a strategic partnership with Worthington Industries Inc. to boost the innovations in IoT, smart manufacturing, sustainability, and data & analytics. Under this agreement, the Worthington will invest around USD 10 million into the innovative technologies that would enhance company market range and enable them to serve better to current and as well as future market.

In April 2021, Bedford Reinforced Plastics announced the launch of its new ReadySeries, a very quick-ship easy to install modular solution that meets the need of safety structures effectively. The new system includes industrial platforms, walkaways, catwalks, handrails, guardrails, pedestrian bridges and many more configurations that can be handled quickly and affordably. Scope of the Report

Global FRP Vessels Market, by Fiber

- Glass

- Carbon

- Others

Global FRP Vessels Market, by Resin

- Polyester

- Epoxy

- Others

Global FRP Vessels Market, by Application

- Automotive & Transportation

- Chemicals

- Industrial

- Oil & Gas

- Water & Wastewater

- Others

Global FRP Vessels Market, by Region

- North America

- US

- Canada

- Mexico

- Europe

- UK

- Germany

- France

- Italy

- Spain

- Benelux

- Nordic

- Rest of Europe

- Asia Pacific

- China

- Japan

- South Korea

- Indonesia

- Austalia

- Malaysia

- India

- Rest of Asia Pacific

- South America

- Brazil

- Argentina

- Rest of South America

- Middle East & Africa

- Saudi Arabia

- UAE

- Egypt

- South Africa

- Rest of Middle East & Africa

| Parameters | Indicators |

|---|---|

| Market Size | 2033: USD 20.36 Billion |

| CAGR (2023-2033) | 10.52% |

| Base year | 2022 |

| Forecast Period | 2023-2033 |

| Historical Data | 2021 (2017 to 2020 On Demand) |

| Report Coverage | Revenue Forecast, Competitive Landscape, Growth Factors, and Trends |

| Key Segmentations | Fiber, Resin, Application |

| Geographies Covered | North America, Europe, Asia-Pacific, South America, Middle East, Africa |

| Key Vendors | Faber Industries, Luxfer Group, ZCL Composites Inc., Hexagon Composites, Everest Kanto Cylinders Ltd., Quantum Fuel Systems, Avanco Group, Denali Incorporated, ULLIT and Worthington Industries Inc. |

| Key Market Opportunities | · Growing Demand in Water Treatment · Renewable Energy Projects |

| Key Market Drivers | · Corrosion Resistance and Cost-effectiveness · Lightweight and Durable |

REPORT CONTENT BRIEF:

- High-level analysis of the current and future FRP Vessels Market trends and opportunities

- Detailed analysis of current market drivers, restraining factors, and opportunities in the future

- FRP Vessels Market historical market size for the year 2021, and forecast from 2023 to 2033

- FRP Vessels Market share analysis at each product level

- Competitor analysis with detailed insight into its product segment, Government & Defense strength, and strategies adopted.

- Identifies key strategies adopted including product launches and developments, mergers and acquisitions, joint ventures, collaborations, and partnerships as well as funding taken and investment done, among others.

- To identify and understand the various factors involved in the global FRP Vessels Market affected by the pandemic

- To provide a detailed insight into the major companies operating in the market. The profiling will include the Government & Defense health of the company’s past 2-3 years with segmental and regional revenue breakup, product offering, recent developments, SWOT analysis, and key strategies.

Frequently Asked Questions (FAQ)

What is the study period of this market?

The study period of the global FRP Vessels Market is 2021- 2033

What is the growth rate of the global FRP Vessels Market?

The global FRP Vessels Market is growing at a CAGR of 10.52% over the next 10 years

Which region has the highest growth rate in the market of FRP Vessels Market?

Asia Pacific is expected to register the highest CAGR during 2023-2033

Which region has the largest share of the global FRP Vessels Market?

North America holds the largest share in 2022

Who are the key players in the global FRP Vessels Market?

Faber Industries, Luxfer Group, ZCL Composites Inc., Hexagon Composites, Everest Kanto Cylinders Ltd., Quantum Fuel Systems, Avanco Group, Denali Incorporated, ULLIT and Worthington Industries Inc are the major companies operating in the market.

Do you offer Post Sale Support?

Yes, we offer 16 hours of analyst support to solve the queries

Do you sell particular sections of a report?

Yes, we provide regional as well as country-level reports. Other than this we also provide a sectional report. Please get in contact with our sales representatives.

Press Release

Global Pharmaceutical Manufacturing Market to Reach $1.38 Trillion by 2035 with 7.35% CAGR, New Research Shows

The Global Mammography Market Is Estimated To Record a CAGR of Around 10.29% During The Forecast Period

Glue Stick Market to Reach USD 2.35 Billion by 2034

Podiatry Service Market to Reach USD 11.88 Billion by 2034

Microfluidics Technology Market to Reach USD 32.58 Billion by 2034

Ferric Chloride Market to Reach USD 10.65 Billion by 2034

Family Practice EMR Software Market to Reach USD 21.52 Billion by 2034

Electric Hairbrush Market to Reach USD 15.95 Billion by 2034

Daily Bamboo Products Market to Reach USD 143.52 Billion by 2034

Cross-border E-commerce Logistics Market to Reach USD 112.65 Billion by 2034

Table of Content

CHAPTER 1. Executive Summary CHAPTER 2. Scope of the Study 2.1. Market Definition 2.2. Market Scope & Segmentation 2.2.1. Objective of Report CHAPTER 3. Evolve BI Methodology 3.1. Data Collection & Validation Approach 3.2. Market Size Estimation and Forecast CHAPTER 4. Exclusive Analysis 4.1. Market Opportunity Score 4.1.1. Fiber Segement – Market Opportunity Score 4.1.2. Application Segment – Market Opportunity Score 4.1.3. Resin Segment – Market Opportunity Score 4.2. Key Market Influencing Indicators CHAPTER 5. Market Insights and Trends 5.1. Value Chain Analysis 5.1.1. Raw Material 5.1.2. Manufacturing Process 5.1.3. Distribution Channel 5.1.4. End User 5.2. Porter’s Five Forces Analysis 5.2.1. Bargaining Power of Buyers 5.2.2. Bargaining Power of Suppliers 5.2.3. Threat of New Entrant 5.2.4. Threat of Substitute 5.2.5. Industry Rivalry 5.3. COVID-19 Impact and Post COVID Scenario on FRP Vessels Market 5.3.1. Impact of COVID-19 5.3.2. Government Support and Industry Revival Policies 5.3.3. Measures Taken by Companies to Mitigate Negative Impact 5.3.4. Post COVID Trend CHAPTER 6. Market Dynamics 6.1. Introduction 6.2. Drivers 6.2.1. Driver 1 6.2.2. Driver 2 6.2.3. Driver 3 6.3. Restraints 6.3.1. Restraint 1 6.3.2. Restraint 2 6.4. Opportunity 6.4.1. Opportunity 1 CHAPTER 7. FRP Vessels Market, By Fiber 7.1. Introduction 7.1.1. Glass 7.1.2. Carbon 7.1.3. Others CHAPTER 8 FRP Vessels Market, By Application 8.1. Introduction 8.1.1. Automotive & Transportation 8.1.2. Chemicals 8.1.3. Industrial 8.1.4. Oil & Gas 8.1.5. Water & Wastewater 8.1.6. Others CHAPTER 9. FRP Vessels Market, By Resin 9.1. Introduction 9.1.1. Polyester 9.1.2 Epoxy 9.1.3. Others CHAPTER 10. FRP Vessels Market, By Region 10.1. Introduction 10.2. NORTH AMERICA 10.2.1. North America: Market Size and Forecast, By Country, 2023 – 2033 ($ Million) 10.2.2. North America: Market Size and Forecast, By Fiber, 2023 – 2033 ($ Million) 10.2.3. North America: Market Size and Forecast, By Application, 2023 – 2033 ($ Million) 10.2.4. North America: Market Size and Forecast, By Resin, 2023 – 2033 ($ Million) 10.2.5. US 10.2.5.1. US: Market Size and Forecast, By Fiber, 2023 – 2033 ($ Million) 10.2.5.2. US: Market Size and Forecast, By Application, 2023 – 2033 ($ Million) 10.2.5.3. US: Market Size and Forecast, By Resin, 2023 – 2033 ($ Million) 10.2.6. CANADA 10.2.6.1. Canada: Market Size and Forecast, By Fiber, 2023 – 2033 ($ Million) 10.2.6.2. Canada: Market Size and Forecast, By Application, 2023 – 2033 ($ Million) 10.2.6.3. Canada: Market Size and Forecast, By Resin, 2023 – 2033 ($ Million) 10.2.7. MEXICO 10.2.7.1. Mexico: Market Size and Forecast, By Fiber, 2023 – 2033 ($ Million) 10.2.7.2. Mexico: Market Size and Forecast, By Application, 2023 – 2033 ($ Million) 10.2.7.3. Mexico: Market Size and Forecast, By Resin, 2023 – 2033 ($ Million) 10.3. Europe 10.3.1. Europe: Market Size and Forecast, By Country, 2023 – 2033 ($ Million) 10.3.2. Europe: Market Size and Forecast, By Fiber, 2023 – 2033 ($ Million) 10.3.3. Europe: Market Size and Forecast, By Application, 2023 – 2033 ($ Million) 10.3.4. Europe: Market Size and Forecast, By Resin, 2023 – 2033 ($ Million) 10.3.5. U.K. 10.3.5.1. U.K.: Market Size and Forecast, By Fiber, 2023 – 2033 ($ Million) 10.3.5.2. U.K.: Market Size and Forecast, By Application, 2023 – 2033 ($ Million) 10.3.5.3. U.K.: Market Size and Forecast, By Resin, 2023 – 2033 ($ Million) 10.3.6. GERMANY 10.3.6.1. Germany: Market Size and Forecast, By Fiber, 2023 – 2033 ($ Million) 10.3.6.2. Germany: Market Size and Forecast, By Application, 2023 – 2033 ($ Million) 10.3.6.3. Germany: Market Size and Forecast, By Resin, 2023 – 2033 ($ Million) 10.3.7. FRANCE 10.3.7.1. France: Market Size and Forecast, By Fiber, 2023 – 2033 ($ Million) 10.3.7.2. France: Market Size and Forecast, By Application, 2023 – 2033 ($ Million) 10.3.7.3. France: Market Size and Forecast, By Resin, 2023 – 2033 ($ Million) 10.3.8. ITALY 10.3.8.1. Italy: Market Size and Forecast, By Fiber, 2023 – 2033 ($ Million) 10.3.8.2. Italy: Market Size and Forecast, By Application, 2023 – 2033 ($ Million) 10.3.8.3. Italy: Market Size and Forecast, By Resin, 2023 – 2033 ($ Million) 10.3.9. SPAIN 10.3.9.1. Spain: Market Size and Forecast, By Fiber, 2023 – 2033 ($ Million) 10.3.9.2. Spain: Market Size and Forecast, By Application, 2023 – 2033 ($ Million) 10.3.9.3. Spain: Market Size and Forecast, By Resin, 2023 – 2033 ($ Million) 10.3.10. BENELUX 10.3.10.1. BeNeLux: Market Size and Forecast, By Fiber, 2023 – 2033 ($ Million) 10.3.10.2. BeNeLux: Market Size and Forecast, By Application, 2023 – 2033 ($ Million) 10.3.10.3. BeNeLux: Market Size and Forecast, By Resin, 2023 – 2033 ($ Million) 10.3.11. RUSSIA 10.3.11.1. Russia: Market Size and Forecast, By Fiber, 2023 – 2033 ($ Million) 10.3.11.2. Russia: Market Size and Forecast, By Application, 2023 – 2033 ($ Million) 10.3.11.3. Russia: Market Size and Forecast, By Resin, 2023 – 2033 ($ Million) 10.3.12. REST OF EUROPE 10.3.12.1. Rest of Europe: Market Size and Forecast, By Fiber, 2023 – 2033 ($ Million) 10.3.12.2. Rest of Europe: Market Size and Forecast, By Application, 2023 – 2033 ($ Million) 10.3.12.3. Rest of Europe: Market Size and Forecast, By Resin, 2023 – 2033 ($ Million) 10.4. Asia Pacific 10.4.1. Asia Pacific: Market Size and Forecast, By Country, 2023 – 2033 ($ Million) 10.4.2. Asia Pacific: Market Size and Forecast, By Fiber, 2023 – 2033 ($ Million) 10.4.3. Asia Pacific: Market Size and Forecast, By Application, 2023 – 2033 ($ Million) 10.4.4. Asia Pacific: Market Size and Forecast, By Resin, 2023 – 2033 ($ Million) 10.4.5. CHINA 10.4.5.1. China: Market Size and Forecast, By Fiber, 2023 – 2033 ($ Million) 10.4.5.2. China: Market Size and Forecast, By Application, 2023 – 2033 ($ Million) 10.4.5.3. China: Market Size and Forecast, By Resin, 2023 – 2033 ($ Million) 10.4.6. JAPAN 10.4.6.1. Japan: Market Size and Forecast, By Fiber, 2023 – 2033 ($ Million) 10.4.6.2. Japan: Market Size and Forecast, By Application, 2023 – 2033 ($ Million) 10.4.6.3. Japan: Market Size and Forecast, By Resin, 2023 – 2033 ($ Million) 10.4.7. INDIA 10.4.7.1. India: Market Size and Forecast, By Fiber, 2023 – 2033 ($ Million) 10.4.7.2. India: Market Size and Forecast, By Application, 2023 – 2033 ($ Million) 10.4.7.3. India: Market Size and Forecast, By Resin, 2023 – 2033 ($ Million) 10.4.8. SOUTH KOREA 10.4.8.1. South Korea: Market Size and Forecast, By Fiber, 2023 – 2033 ($ Million) 10.4.8.2. South Korea: Market Size and Forecast, By Application, 2023 – 2033 ($ Million) 10.4.8.3. South Korea: Market Size and Forecast, By Resin, 2023 – 2033 ($ Million) 10.4.9. THAILAND 10.4.9.1. Thailand: Market Size and Forecast, By Fiber, 2023 – 2033 ($ Million) 10.4.9.2. Thailand: Market Size and Forecast, By Application, 2023 – 2033 ($ Million) 10.4.9.3. Thailand: Market Size and Forecast, By Resin, 2023 – 2033 ($ Million) 10.4.10. INDONESIA 10.4.10.1. Indonesia: Market Size and Forecast, By Fiber, 2023 – 2033 ($ Million) 10.4.10.2. Indonesia: Market Size and Forecast, By Application, 2023 – 2033 ($ Million) 10.4.10.3. Indonesia: Market Size and Forecast, By Resin, 2023 – 2033 ($ Million) 10.4.11. MALAYSIA 10.4.11.1. Malaysia: Market Size and Forecast, By Fiber, 2023 – 2033 ($ Million) 10.4.11.2. Malaysia: Market Size and Forecast, By Application, 2023 – 2033 ($ Million) 10.4.11.3. Malaysia: Market Size and Forecast, By Resin, 2023 – 2033 ($ Million) 10.4.12. AUSTRALIA 10.4.12.1. Australia: Market Size and Forecast, By Fiber, 2023 – 2033 ($ Million) 10.4.12.2. Australia: Market Size and Forecast, By Application, 2023 – 2033 ($ Million) 10.4.12.3. Australia: Market Size and Forecast, By Resin, 2023 – 2033 ($ Million) 10.4.13. REST FO ASIA PACIFIC 10.4.13.1. Rest fo Asia Pacific: Market Size and Forecast, By Fiber, 2023 – 2033 ($ Million) 10.4.13.2. Rest fo Asia Pacific: Market Size and Forecast, By Application, 2023 – 2033 ($ Million) 10.4.13.3. Rest fo Asia Pacific: Market Size and Forecast, By Resin, 2023 – 2033 ($ Million) 10.5. South America 10.5.1. South America: Market Size and Forecast, By Country, 2023 – 2033 ($ Million) 10.5.2. South America: Market Size and Forecast, By Fiber, 2023 – 2033 ($ Million) 10.5.3. South America: Market Size and Forecast, By Application, 2023 – 2033 ($ Million) 10.5.4. South America: Market Size and Forecast, By Resin, 2023 – 2033 ($ Million) 10.5.5. BRAZIL 10.5.5.1. Brazil: Market Size and Forecast, By Fiber, 2023 – 2033 ($ Million) 10.5.5.2. Brazil: Market Size and Forecast, By Application, 2023 – 2033 ($ Million) 10.5.5.3. Brazil: Market Size and Forecast, By Resin, 2023 – 2033 ($ Million) 10.5.6. ARGENTINA 10.5.6.1. Argentina: Market Size and Forecast, By Fiber, 2023 – 2033 ($ Million) 10.5.6.2. Argentina: Market Size and Forecast, By Application, 2023 – 2033 ($ Million) 10.5.6.3. Argentina: Market Size and Forecast, By Resin, 2023 – 2033 ($ Million) 10.5.7. REST OF SOUTH AMERICA 10.5.7.1. Rest of South America: Market Size and Forecast, By Fiber, 2023 – 2033 ($ Million) 10.5.7.2. Rest of South America: Market Size and Forecast, By Application, 2023 – 2033 ($ Million) 10.5.7.3. Rest of South America: Market Size and Forecast, By Resin, 2023 – 2033 ($ Million) 10.6. Middle East & Africa 10.6.1. Middle East & Africa: Market Size and Forecast, By Country, 2023 – 2033 ($ Million) 10.6.2. Middle East & Africa: Market Size and Forecast, By Fiber, 2023 – 2033 ($ Million) 10.6.3. Middle East & Africa: Market Size and Forecast, By Application, 2023 – 2033 ($ Million) 10.6.4. Middle East & Africa: Market Size and Forecast, By Resin, 2023 – 2033 ($ Million) 10.6.5. SAUDI ARABIA 10.6.5.1. Saudi Arabia: Market Size and Forecast, By Fiber, 2023 – 2033 ($ Million) 10.6.5.2. Saudi Arabia: Market Size and Forecast, By Application, 2023 – 2033 ($ Million) 10.6.5.3. Saudi Arabia: Market Size and Forecast, By Resin, 2023 – 2033 ($ Million) 10.6.6. UAE 10.6.6.1. UAE: Market Size and Forecast, By Fiber, 2023 – 2033 ($ Million) 10.6.6.2. UAE: Market Size and Forecast, By Application, 2023 – 2033 ($ Million) 10.6.6.3. UAE: Market Size and Forecast, By Resin, 2023 – 2033 ($ Million) 10.6.7. EGYPT 10.6.7.1. Egypt: Market Size and Forecast, By Fiber, 2023 – 2033 ($ Million) 10.6.7.2. Egypt: Market Size and Forecast, By Application, 2023 – 2033 ($ Million) 10.6.7.3. Egypt: Market Size and Forecast, By Resin, 2023 – 2033 ($ Million) 10.6.8. SOUTH AFRICA 10.6.8.1. South Africa: Market Size and Forecast, By Fiber, 2023 – 2033 ($ Million) 10.6.8.2. South Africa: Market Size and Forecast, By Application, 2023 – 2033 ($ Million) 10.6.8.3. South Africa: Market Size and Forecast, By Resin, 2023 – 2033 ($ Million) 10.6.9. REST OF MIDDLE EAST & AFRICA 10.6.9.1. Rest of Middle East & Africa: Market Size and Forecast, By Fiberss, 2023 – 2033 ($ Million) 10.6.9.2. Rest of Middle East & Africa: Market Size and Forecast, By Application, 2023 – 2033 ($ Million) 10.6.9.3. Rest of Middle East & Africa: Market Size and Forecast, By Resin, 2023 – 2033 ($ Million) CHAPTER 12. Competitive Landscape 12.1. Competitior Benchmarking 2023 12.2. Market Share Analysis 12.3. Key Developments Analysis By Top 5 Companies 12.4. Market Share Acquisition Strategies: Analysis of Key Approaches Employed by Top Players CHAPTER 13. Company Profiles 13.1. Faber Industries 13.1.1. Hanon Systems 13.1.2. Financial Analysis 13.1.2.1. Business Segment Revenue, 2020, 2021, 2022, $ Million 13.1.2.2. Geographic Revenue Mix, 2022 (% Share) 13.1.3. Product Portfolio 13.1.4. Recent Development and Strategies Adopted 13.1.5. SWOT Analysis 13.2. Luxfer Group 13.3. ZCL Composites Inc. 13.4. Hexagon Composites 13.5. Everest Kanto Cylinders Ltd. 13.6. Quantum Fuel Systems 13.7. Avanco Group 13.8. Denali Incorporated 13.9 ULLIT 13.10 Worthington Industries Inc

Connect to Analyst

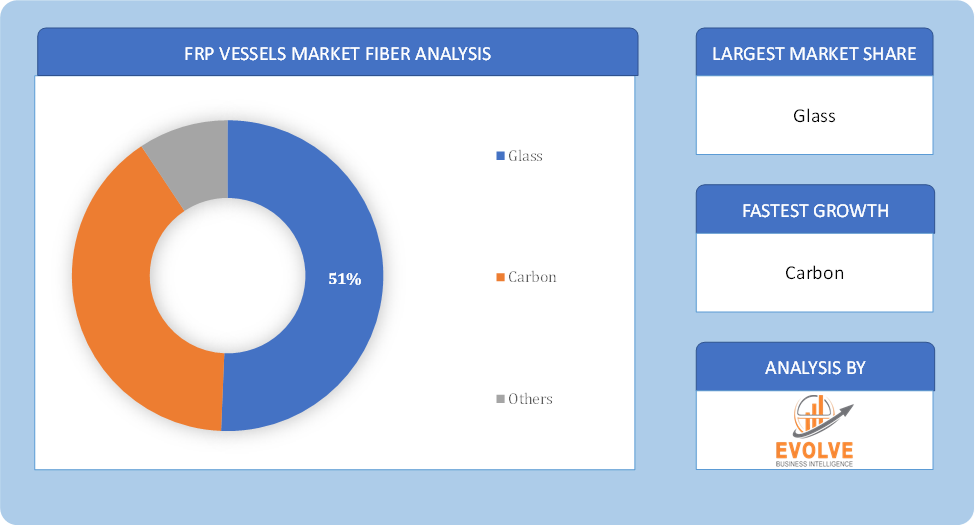

Research Methodology

FRP Vessels North America Market

FRP Vessels North America Market