FRP Cable Tray Market Analysis and Global Forecast 2023-2033

$ 1,390.00 – $ 5,520.00Price range: $ 1,390.00 through $ 5,520.00

FRP Cable Tray Market Research Report: Information By Type (Ladder Cable Tray, Perforated Cable Tray, Channel Cable Tray, Solid Cable Tray), By Application (Oil & Gas, Petrochemical & Refinery Plant, Chemical Plant, Power Plant, Building Construction), and by Region — Forecast till 2033

FRP Cable Tray Market Overview

The FRP Cable Tray Market Size is expected to reach USD 607.2 Billion by 2033. The FRP Cable Tray Market industry size accounted for USD 397.3Billion in 2023 and is expected to expand at a compound annual growth rate (CAGR) of 4.41% from 2023 to 2033. FRP (Fiber-Reinforced Plastic) Cable Tray Market refers to the market for cable trays made from fiber-reinforced plastic materials. Cable trays are support systems used in the construction and electrical industry to securely manage and organize cables and wires within buildings and industrial facilities. These trays are designed to provide a safe and efficient way to route and support various types of electrical and communication cables.

Fiber-reinforced plastic cable trays are constructed using a composite material made of plastic reinforced with fibers such as fiberglass. FRP offers advantages like corrosion resistance, lightweight, high strength, and durability, making it a popular choice for cable management systems, especially in corrosive or challenging environments where traditional metal trays may not be suitable.

The FRP Cable Tray Market involves the production, distribution, and sale of cable trays made from FRP materials. This market includes manufacturers, suppliers, distributors, and end-users such as construction companies, electrical contractors, industrial facilities, and infrastructure projects that require cable management solutions. The market also involves research and development to improve the design, performance, and sustainability of FRP cable trays. Factors influencing this market may include technological advancements, infrastructure development, regulations, and the demand for efficient cable management solutions.

Global FRP Cable Tray Market Synopsis

COVID-19 Impact Analysis

The COVID-19 has a specific impact on the FRP Cable Tray Market. The pandemic caused disruptions in global supply chains due to factory closures, transportation restrictions, and workforce challenges. This could have impacted the production and availability of raw materials needed to manufacture FRP cable trays, thus affecting the overall market supply. Economic uncertainties during the pandemic may have led to fluctuating demand for construction and infrastructure projects, affecting the demand for FRP cable trays. Some projects might have been delayed or put on hold, impacting the need for cable management solutions. With an increase in remote working arrangements, there might have been a shift in focus towards enhancing IT infrastructure rather than traditional infrastructure projects. This could have influenced the demand for cable management solutions like FRP cable trays. The pandemic could have impacted the cost of raw materials, labor, and transportation, influencing the overall pricing of FRP cable trays. Economic instability might have affected the budget allocations for infrastructure projects, potentially influencing purchasing decisions.

FRP Cable Tray Market Dynamics

The major factors that have impacted the growth of FRP Cable Tray Market are as follows:

Drivers:

Ø Flexibility and Customization

FRP cable trays are lightweight compared to traditional metal trays, making them easier to handle and install. This characteristic can lead to quicker installation, reduced labor costs, and increased overall efficiency of cable management projects. FRP cable trays can be easily molded into various shapes and sizes, allowing for customization to fit specific project requirements. This flexibility in design and customization options enhances their suitability for diverse applications and projects. The growing focus on renewable energy sources, such as wind and solar power, requires extensive cabling and wiring solutions. FRP cable trays, being resistant to environmental factors, are increasingly adopted in renewable energy projects. FRP cable trays are considered environmentally friendly due to their recyclability and the use of composite materials, which can reduce the demand for non-renewable resources. The focus on sustainability and eco-friendly solutions drives the adoption of FRP cable trays.

Restraint:

- Perception of High Initial Investment Costs

The initial cost of manufacturing FRP cable trays can be relatively high due to the specialized equipment, technology, and materials required for the production process. This initial investment can act as a restraint for smaller manufacturers or projects with budget constraints. FRP materials have certain limitations in terms of load-bearing capacity compared to metals like steel. This limitation restricts the application of FRP cable trays in heavy-duty industries or applications requiring extremely high load-bearing capabilities. FRP materials may have limitations in terms of high-temperature resistance compared to metals like steel. In applications where extreme heat or fire resistance is critical, alternative materials might be preferred over FRP.

Opportunity:

⮚ Sustainable and Eco-Friendly Solutions

The increasing focus on sustainability and environmental concerns provides an opportunity for FRP cable trays as a more sustainable alternative to traditional materials. FRP is recyclable and can be manufactured using eco-friendly processes, aligning with the global push for greener solutions. The expansion of renewable energy projects, such as solar and wind farms, presents a significant opportunity for FRP cable trays. These projects require robust cable management systems, and FRP’s corrosion resistance and durability make it a suitable choice for harsh outdoor environments. The demand for corrosion-resistant cable management solutions remains high, especially in industries where exposure to corrosive substances is prevalent. Highlighting the corrosion resistance properties of FRP cable trays can open doors to various industries facing these challenges.

FRP Cable Tray Market Segment Overview

By Type

Based on Type, the market is segmented based on Ladder Cable Tray, Perforated Cable Tray, Channel Cable Tray and Solid Cable Tray. The ladder-type segment is projected to lead the market during the forecast due to its extended support in span spacings, effective heat dissipation, and easy running in & out of cables. Additionally, channel type products are also set to observe substantial growth rate owing to different factors such as economic cable management alternatives and the limited requirement for maintenance with a limited number of cables.

By Application

Based on Application, the market has been divided into Oil & Gas, Petrochemical & Refinery Plant, Chemical Plant, Power Plant and Building Construction. The oil & gas segment is anticipated to observe considerable growth opportunities owing to the increasing exploration of old and new hydrocarbon assets across the globe. Consequently, growing building activities to renovate the prevailing substructures coupled with creating the new ones to support national objectives is likely to augment the construction segment landscape.

Global FRP Cable Tray Market Regional Analysis

Based on region, the global FRP Cable Tray Market has been divided into North America, Europe, Asia-Pacific, the Middle East & Africa, and Latin America. North America is projected to dominate the use of the FRP Cable Tray Market followed by the Asia-Pacific and Europe regions.

North America Market

North America holds a dominant position in the FRP Cable Tray Market. The region’s dominance can be attributed to various factors. North America has a mature market for cable management solutions, including FRP cable trays. The region is characterized by a strong emphasis on technological advancements, sustainable practices, and regulatory compliance. Increasing investment in renewable energy projects, urbanization, modernization of infrastructure, and the demand for sustainable and corrosion-resistant cable management solutions are driving the FRP Cable Tray Market in this region.

Asia-Pacific Market

The Asia-Pacific region has indeed emerged as the fastest-growing market for the FRP Cable Tray Market industry. Asia-Pacific is a rapidly growing market for FRP cable trays due to robust industrialization, urbanization, and substantial investments in infrastructure projects. The region is a major consumer of cable management solutions. Rapid urban development, increasing power generation capacity, government initiatives for smart cities, and a focus on sustainable solutions are driving the demand for FRP cable trays in this region.

Competitive Landscape

The global FRP Cable Tray Market is highly competitive, with numerous players offering a wide range of software solutions. The competitive landscape is characterized by the presence of established companies, as well as emerging startups and niche players. To increase their market position and attract a wide consumer base, the businesses are employing various strategies, such as product launches, and strategic alliances.

Prominent Players:

- Indiana Group

- MP Husky

- Ercon

- Hebei Shengrun Glass Steel

- Hebei Longxin

- Taiyun Jiancai

- Ventura Fibre

- Aeron Composite

- Intralink Techno Sdn Bhd

- Sintex Industries Limited.

Scope of the Report

Global FRP Cable Tray Market, by Type

- Ladder Cable Tray

- Perforated Cable Tray

- Channel Cable Tray

- Solid Cable Tray

Global FRP Cable Tray Market, by Application

- Oil & Gas

- Petrochemical & Refinery Plant

- Chemical Plant

- Power Plant

- Building Construction.

Global FRP Cable Tray Market, by Region

- North America

- US

- Canada

- Mexico

- Europe

- UK

- Germany

- France

- Italy

- Spain

- Benelux

- Nordic

- Rest of Europe

- Asia Pacific

- China

- Japan

- South Korea

- Indonesia

- Austalia

- Malaysia

- India

- Rest of Asia Pacific

- South America

- Brazil

- Argentina

- Rest of SouthAmerica

- Middle East &Africa

- Saudi Arabia

- UAE

- Egypt

- SouthAfrica

- Rest of Middle East & Africa

| Parameters | Indicators |

|---|---|

| Market Size | 2033: $USD607.2Billion |

| CAGR | 4.41% CAGR (2023-2033) |

| Base year | 2022 |

| Forecast Period | 2023-2033 |

| Historical Data | 2021 |

| Report Coverage | Revenue Forecast, Competitive Landscape, Growth Factors, and Trends |

| Key Segmentations | Type, Application |

| Geographies Covered | North America, Europe, Asia-Pacific, Latin America, Middle East, Africa |

| Key Vendors | Indiana Group, MP Husky, Ercon, Hebei Shengrun Glass Steel, Hebei Longxin, Taiyun Jiancai, Ventura Fibre, Aeron Composite, Intralink Techno Sdn Bhd and Sintex Industries Limited. |

| Key Market Opportunities | • Sustainable and Eco-Friendly Solutions |

| Key Market Drivers | • Technological Advancements • Flexibility and Customization |

REPORT CONTENT BRIEF:

- High-level analysis of the current and future FRP Cable Tray Market trends and opportunities

- Detailed analysis of current market drivers, restraining factors, and opportunities in the future

- FRP Cable Tray Market historical market size for the year 2021, and forecast from 2023 to 2033

- FRP Cable Tray Market share analysis at each product level

- Competitor analysis with detailed insight into its product segment, Government & Defense strength, and strategies adopted.

- Identifies key strategies adopted including product launches and developments, mergers and acquisitions, joint ventures, collaborations, and partnerships as well as funding taken and investment done, among others.

- To identify and understand the various factors involved in the global FRP Cable Tray Market affected by the pandemic

- To provide a detailed insight into the major companies operating in the market. The profiling will include the Government & Defense health of the company’s past 2-3 years with segmental and regional revenue breakup, product offering, recent developments, SWOT analysis, and key strategies.

Frequently Asked Questions (FAQ)

Press Release

Global Pharmaceutical Manufacturing Market to Reach $1.38 Trillion by 2035 with 7.35% CAGR, New Research Shows

The Global Mammography Market Is Estimated To Record a CAGR of Around 10.29% During The Forecast Period

Glue Stick Market to Reach USD 2.35 Billion by 2034

Podiatry Service Market to Reach USD 11.88 Billion by 2034

Microfluidics Technology Market to Reach USD 32.58 Billion by 2034

Ferric Chloride Market to Reach USD 10.65 Billion by 2034

Family Practice EMR Software Market to Reach USD 21.52 Billion by 2034

Electric Hairbrush Market to Reach USD 15.95 Billion by 2034

Daily Bamboo Products Market to Reach USD 143.52 Billion by 2034

Cross-border E-commerce Logistics Market to Reach USD 112.65 Billion by 2034

1. What is the study period of this market?

- The study period of the global FRP Cable Tray Market is 2021- 2033

2. What is the growth rate of the global FRP Cable Tray Market?

- The global FRP Cable Tray Market is growing at a CAGR of 4.41% over the next 10 years

3. Which region has the highest growth rate in the market of FRP Cable Tray Market?

- Asia Pacific is expected to register the highest CAGR during 2023-2033

4. Which region has the largest share of the global FRP Cable Tray Market?

- North Americaholds the largest share in 2022

5. Who are the key players in the global FRP Cable Tray Market?

- Indiana Group, MP Husky, Ercon, Hebei Shengrun Glass Steel, Hebei Longxin, Taiyun Jiancai, Ventura Fibre, Aeron Composite, Intralink Techno Sdn Bhd and Sintex Industries Limited. are the major companies operating in the market.

6. Do you offer Post Sale Support?

- Yes, we offer 16 hours of analyst support to solve the queries

7. Do you sell particular sections of a report?

Yes, we provide regional as well as country-level reports. Other than this we also provide a sectional report. Please get in contact with our sales representatives.

Table of Content

Chapter 1. Executive Summary Chapter 2. Scope Of The Study 2.1. Market Definition 2.2. Scope Of The Study 2.2.1. Objectives of Report 2.2.2. Limitations 2.3. Market Structure Chapter 3. Evolve BI Methodology Chapter 4. Market Insights and Trends 4.1. Supply/ Value Chain Analysis 4.1.1. Raw End Users Providers 4.1.2. Manufacturing Process 4.1.3. Distributors/Retailers 4.1.4. End-Use Industry 4.2. Porter’s Five Forces Analysis 4.2.1. Threat Of New Entrants 4.2.2. Bargaining Power Of Buyers 4.2.3. Bargaining Power Of Suppliers 4.2.4. Threat Of Substitutes 4.2.5. Industry Rivalry 4.3. Impact Of COVID-19 on the FRP Cable Tray Market 4.3.1. Impact on Market Size 4.3.2. End-Use Industry Trend, Preferences, and Budget Impact 4.3.3. Regulatory Framework/Government Policies 4.3.4. Key Players' Strategy to Tackle Negative Impact 4.3.5. Opportunity Window 4.4. Technology Overview 12.28. Macro factor 4.6. Micro Factor 4.7.Demand Supply Gap Analysis of the FRP Cable Tray Market 4.8.Import Analysis of the FRP Cable Tray Market 4.9.Export Analysis of the FRP Cable Tray Market Chapter 5. Market Dynamics 5.1. Introduction 5.2. DROC Analysis 5.2.1. Drivers 5.2.2. Restraints 5.2.3. Opportunities 5.2.4. Challenges 5.3. Patent Analysis 5.4. Industry Roadmap 5.5. Parent/Peer Market Analysis Chapter 6. Global FRP Cable Tray Market, By Type 6.1. Introduction 6.2. Ladder Cable Tray 6.3. Perforated Cable Tray 6.4. Channel Cable Tray 6.5. Solid Cable Tray. Chapter 7. Global FRP Cable Tray Market, By Application 7.1. Introduction 7.2. Oil & Gas 7.3. Petrochemical & Refinery Plant 7.4 Chemical Plant 7.5 Power Plant 7.6 Building Construction Chapter 8. Global FRP Cable Tray Market, By Region 8.1. Introduction 8.2. North America 8.2.1. Introduction 8.2.2. Driving Factors, Opportunity Analyzed, and Key Trends 8.2.3. Market Size and Forecast, By Country, 2023-2033 8.2.4. Market Size and Forecast, By Product Type, 2023-2033 8.2.5. Market Size and Forecast, By End User, 2023-2033 8.2.6. US 8.2.6.1. Introduction 8.2.6.2. Driving Factors, Opportunity Analyzed, and Key Trends 8.2.6.3. Market Size and Forecast, By Product Type, 2023-2033 8.2.6.4. Market Size and Forecast, By End User, 2023-2033 8.2.7. Canada 8.2.7.1. Introduction 8.2.7.2. Driving Factors, Opportunity Analyzed, and Key Trends 8.2.7.4. Market Size and Forecast, By Product Type, 2023-2033 8.2.7.5. Market Size and Forecast, By End User, 2023-2033 8.3. Europe 8.3.1. Introduction 8.3.2. Driving Factors, Opportunity Analyzed, and Key Trends 8.3.3. Market Size and Forecast, By Country, 2023-2033 8.3.4. Market Size and Forecast, By Product Type, 2023-2033 8.3.5. Market Size and Forecast, By End User, 2023-2033 8.3.6. Germany 8.3.6.1. Introduction 8.3.6.2. Driving Factors, Opportunity Analyzed, and Key Trends 8.3.6.3. Market Size and Forecast, By Product Type, 2023-2033 8.3.6.4. Market Size and Forecast, By End User, 2023-2033 8.3.7. France 8.3.7.1. Introduction 8.3.7.2. Driving Factors, Opportunity Analyzed, and Key Trends 8.3.7.3. Market Size and Forecast, By Product Type, 2023-2033 8.3.7.4. Market Size and Forecast, By End User, 2023-2033 8.3.8. UK 8.3.8.1. Introduction 8.3.8.2. Driving Factors, Opportunity Analyzed, and Key Trends 8.3.8.3. Market Size and Forecast, By Product Type, 2023-2033 8.3.8.4. Market Size and Forecast, By End User, 2023-2033 8.3.9. Italy 8.3.9.1. Introduction 8.3.9.2. Driving Factors, Opportunity Analyzed, and Key Trends 8.3.9.3. Market Size and Forecast, By Product Type, 2023-2033 8.3.9.4. Market Size and Forecast, By End User, 2023-2033 8.3.11. Rest Of Europe 8.3.11.1. Introduction 8.3.11.2. Driving Factors, Opportunity Analyzed, and Key Trends 8.3.11.3. Market Size and Forecast, By Product Type, 2023-2033 8.3.11.4. Market Size and Forecast, By End User, 2023-2033 8.4. Asia-Pacific 8.4.1. Introduction 8.4.2. Driving Factors, Opportunity Analyzed, and Key Trends 8.4.3. Market Size and Forecast, By Country, 2023-2033 8.4.4. Market Size and Forecast, By Product Type, 2023-2033 8.12.28. Market Size and Forecast, By End User, 2023-2033 8.4.6. China 8.4.6.1. Introduction 8.4.6.2. Driving Factors, Opportunity Analyzed, and Key Trends 8.4.6.3. Market Size and Forecast, By Product Type, 2023-2033 8.4.6.4. Market Size and Forecast, By End User, 2023-2033 8.4.7. India 8.4.7.1. Introduction 8.4.7.2. Driving Factors, Opportunity Analyzed, and Key Trends 8.4.7.3. Market Size and Forecast, By Product Type, 2023-2033 8.4.7.4. Market Size and Forecast, By End User, 2023-2033 8.4.8. Japan 8.4.8.1. Introduction 8.4.8.2. Driving Factors, Opportunity Analyzed, and Key Trends 8.4.8.3. Market Size and Forecast, By Product Type, 2023-2033 8.4.8.4. Market Size and Forecast, By End User, 2023-2033 8.4.9. South Korea 8.4.9.1. Introduction 8.4.9.2. Driving Factors, Opportunity Analyzed, and Key Trends 8.4.9.3. Market Size and Forecast, By Product Type, 2023-2033 8.4.9.4. Market Size and Forecast, By End User, 2023-2033 8.4.10. Rest Of Asia-Pacific 8.4.10.1. Introduction 8.4.10.2. Driving Factors, Opportunity Analyzed, and Key Trends 8.4.10.3. Market Size and Forecast, By Product Type, 2023-2033 8.4.10.4. Market Size and Forecast, By End User, 2023-2033 8.5. Rest Of The World (RoW) 8.5.1. Introduction 8.5.2. Driving Factors, Opportunity Analyzed, and Key Trends 8.5.3. Market Size and Forecast, By Product Type, 2023-2033 8.5.4. Market Size and Forecast, By End User, 2023-2033 Chapter 9. Company Landscape 9.1. Introduction 9.2. Vendor Share Analysis 9.3. Key Development Analysis 9.4. Competitor Dashboard Chapter 10. Company Profiles 10.1. Indiana Group 10.1.1. Business Overview 10.1.2. Government & Defense Analysis 10.1.2.1. Government & Defense – Existing/Funding 10.1.3. Product Portfolio 10.1.4. Recent Development and Strategies Adopted 10.1.5. SWOT Analysis 10.2. MP Husky 10.2.1. Business Overview 10.2.2. Government & Defense Analysis 10.2.2.1. Government & Defense – Existing/Funding 10.2.3. Product Portfolio 10.2.4. Recent Development and Strategies Adopted 10.2.5. SWOT Analysis 10.3. Ercon 10.3.1. Business Overview 10.3.2. Government & Defense Analysis 10.3.2.1. Government & Defense – Existing/Funding 10.3.3. Product Portfolio 10.3.4. Recent Development and Strategies Adopted 10.3.5. SWOT Analysis 10.4. Hebei Shengrun Glass Steel 10.4.1. Business Overview 10.4.2. Government & Defense Analysis 10.4.2.1. Government & Defense – Existing/Funding 10.4.3. Product Portfolio 10.4.4. Recent Development and Strategies Adopted 10.12.28. SWOT Analysis 10.5. Hebei Longxin 10.5.1. Business Overview 10.5.2. Government & Defense Analysis 10.5.2.1. Government & Defense – Existing/Funding 10.5.3. Product Portfolio 10.5.4. Recent Development and Strategies Adopted 10.5.5. SWOT Analysis 10.6. Taiyun Jiancai 10.6.1. Business Overview 10.6.2. Government & Defense Analysis 10.6.2.1. Government & Defense – Existing/Funding 10.6.3. Product Portfolio 10.6.4. Recent Development and Strategies Adopted 10.6.5. SWOT Analysis 10.7. Ventura Fibre 10.7.1. Business Overview 10.7.2. Government & Defense Analysis 10.7.2.1. Government & Defense – Existing/Funding 10.7.3. Product Portfolio 10.7.4. Recent Development and Strategies Adopted 10.7.5. SWOT Analysis 10.8 Aeron Composite 10.8.1. Business Overview 10.8.2. Government & Defense Analysis 10.8.2.1. Government & Defense – Existing/Funding 10.8.3. Product Portfolio 10.8.4. Recent Development and Strategies Adopted 10.8.5. SWOT Analysis 10.9 Intralink Techno Sdn Bhd 10.9.1. Business Overview 10.9.2. Government & Defense Analysis 10.9.2.1. Government & Defense – Existing/Funding 10.9.3. Product Portfolio 10.9.4. Recent Development and Strategies Adopted 10.9.5. SWOT Analysis 10.10. Sintex Industries Limited. 10.10.1. Business Overview 10.10.2. Government & Defense Analysis 10.10.2.1. Government & Defense – Existing/Funding 10.10.3. Product Portfolio 10.10.4. Recent Development and Strategies Adopted 10.10.5. SWOT Analysis

Connect to Analyst

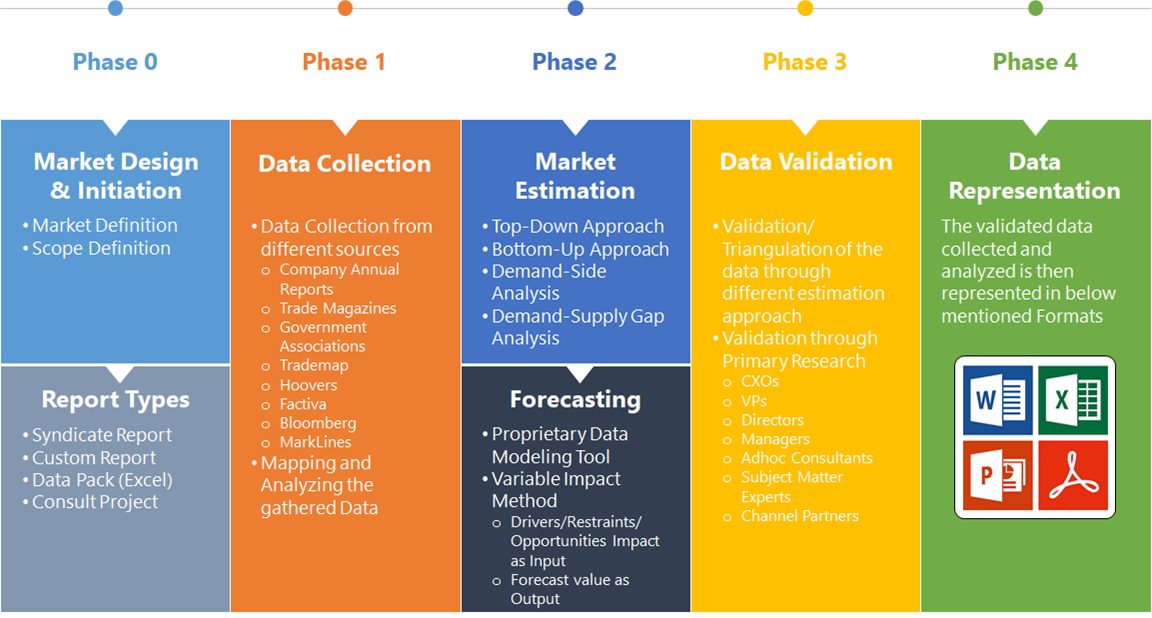

Research Methodology