Smart Manufacturing Market Analysis and Global Forecast 2023-2033

€ 1,230.43 – € 4,886.30Price range: € 1,230.43 through € 4,886.30

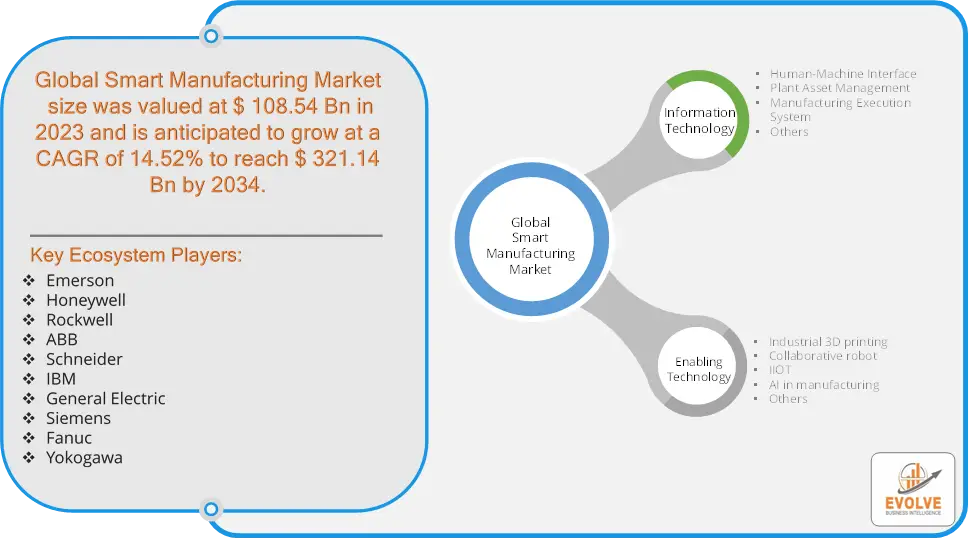

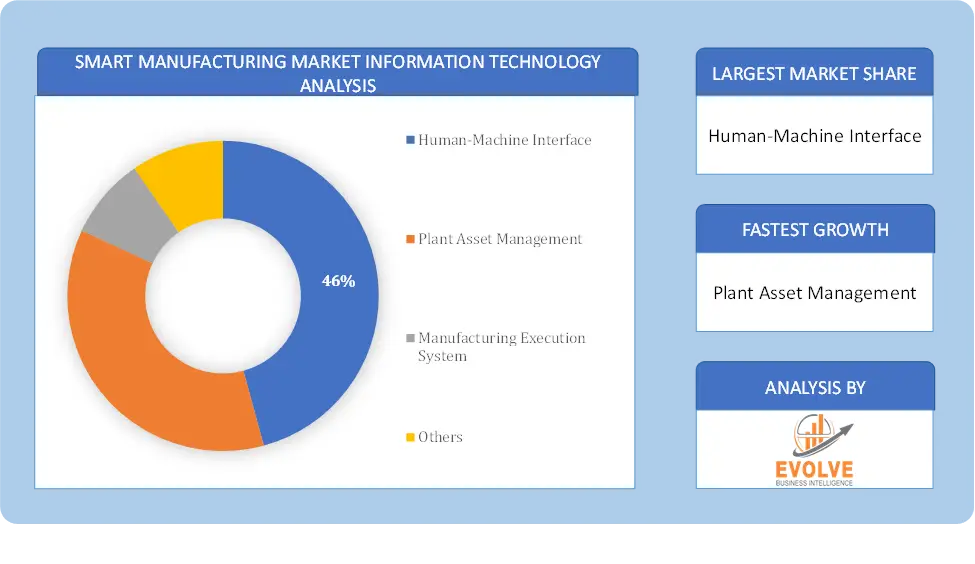

Smart Manufacturing Market Research Report: Information By Information Technology (Human-Machine Interface, Plant Asset Management, Manufacturing Execution System, Others), By Enabling Technology (Industrial 3D printing, Collaborative robot, IIOT, AI in manufacturing, Others), and by Region — Forecast till 2033

Page: 125

Smart Manufacturing Market Overview

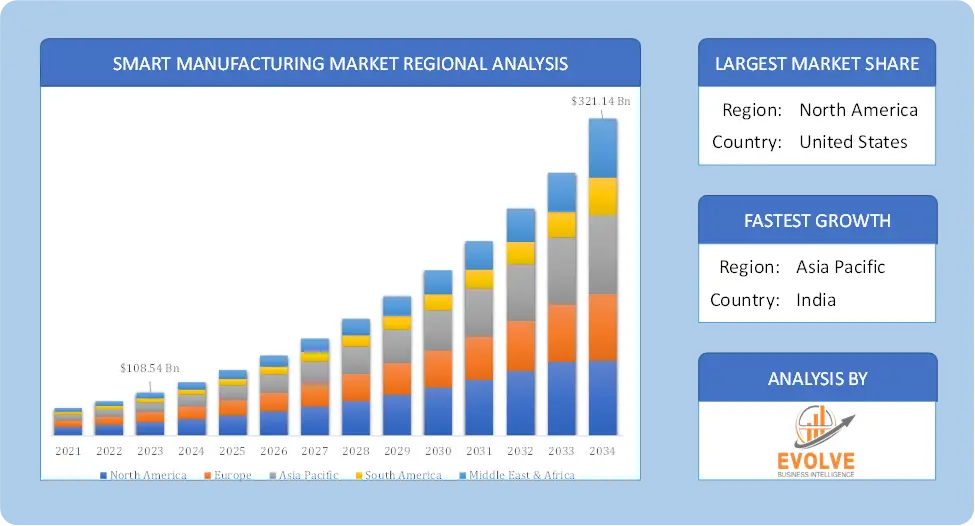

The Smart Manufacturing Market Size is expected to reach USD 321.1 Billion by 2034. The Smart Manufacturing Market industry size accounted for USD 108.54 Billion in 2023 and is expected to expand at a compound annual growth rate (CAGR) of 14.52% from 2021 to 2034. The Smart Manufacturing Market refers to the industry segment focused on the adoption and implementation of advanced technologies in manufacturing processes to improve efficiency, productivity, and flexibility. Smart manufacturing integrates various digital technologies, such as the Internet of Things (IoT), artificial intelligence (AI), machine learning, robotics, big data analytics, and cloud computing, to create a connected and automated production environment.

The Smart Manufacturing Market is driven by the need for increased operational efficiency, the growing demand for mass customization, the rise of Industry 4.0, and the push for sustainable manufacturing practices. It is widely adopted across various industries, including automotive, aerospace, electronics, healthcare, and consumer goods.

Global Smart Manufacturing Market Synopsis

Smart Manufacturing Market Dynamics

Smart Manufacturing Market Dynamics

The major factors that have impacted the growth of Smart Manufacturing Market are as follows:

Drivers:

Ø Industry 4.0 and Digital Transformation

Technological Integration: The ongoing shift towards Industry 4.0, characterized by the integration of digital technologies such as IoT, AI, big data analytics, and robotics, is a significant driver. These technologies enable smarter, more connected, and more efficient manufacturing processes. The need to automate manufacturing processes to enhance productivity, reduce human errors, and lower operational costs is a major driver. Automation also allows for greater flexibility and responsiveness to market changes. Smart manufacturing technologies help optimize energy usage, reduce waste, and improve overall resource efficiency, which leads to significant cost savings. This is particularly important as companies strive to meet sustainability goals. The use of IoT and AI for predictive maintenance reduces downtime and extends the life of machinery, leading to cost savings and increased operational efficiency.

Restraint:

- Perception of High Initial Investment and Implementation Costs

Implementing smart manufacturing technologies requires significant upfront investment in new equipment, software, and infrastructure. Small and medium-sized enterprises (SMEs), in particular, may find these costs prohibitive, limiting their ability to adopt these technologies. The long-term benefits of smart manufacturing, such as improved efficiency and reduced operational costs, may take time to materialize. This delay in realizing ROI can be a deterrent for companies hesitant to make substantial investments without immediate financial returns.

Opportunity:

⮚ Adoption of Advanced Technologies

AI and machine learning are increasingly being integrated into manufacturing processes for predictive maintenance, quality control, and process optimization. Companies that invest in these technologies can gain a competitive advantage by improving efficiency, reducing downtime, and enhancing product quality. The use of digital twins—virtual replicas of physical systems—enables manufacturers to simulate, analyze, and optimize production processes in real-time. This technology offers significant opportunities for reducing costs, improving product design, and enhancing operational efficiency.

Smart Manufacturing Market Segment Overview

By Information Technology

Based on Information technology, the market is segmented based on Human-Machine Interface, Plant Asset Management, Manufacturing Execution System and Others. The Manufacturing Execution System segment dominant the market. MES systems gather real-time data from machines, operators, and other production resources, providing a comprehensive view of the manufacturing process. MES helps in dynamic production scheduling, ensuring that resources are allocated efficiently and production goals are met. It allows manufacturers to adjust schedules in real-time based on changes in demand, availability of resources, or other factors.

Based on Information technology, the market is segmented based on Human-Machine Interface, Plant Asset Management, Manufacturing Execution System and Others. The Manufacturing Execution System segment dominant the market. MES systems gather real-time data from machines, operators, and other production resources, providing a comprehensive view of the manufacturing process. MES helps in dynamic production scheduling, ensuring that resources are allocated efficiently and production goals are met. It allows manufacturers to adjust schedules in real-time based on changes in demand, availability of resources, or other factors.

By Enabling Technology

Based on Enabling Technology, the market segment has been divided into Industrial 3D printing, Collaborative robot, IIOT, AI in manufacturing and Others. The AI in manufacturing segment dominant the market. AI-driven predictive maintenance helps manufacturers anticipate equipment failures before they occur, reducing downtime and maintenance costs. By analyzing data from sensors and machinery, AI can predict when maintenance is needed, allowing for proactive rather than reactive maintenance strategies. AI algorithms analyze production data to identify inefficiencies and optimize manufacturing processes. This includes real-time adjustments to production parameters, optimizing energy consumption, reducing waste, and improving overall throughput.

Global Smart Manufacturing Market Regional Analysis

Based on region, the global Smart Manufacturing Market has been divided into North America, Europe, Asia-Pacific, the Middle East & Africa, and Latin America. North America is projected to dominate the use of the Smart Manufacturing Market followed by the Asia-Pacific and Europe regions.

Smart Manufacturing North America Market

Smart Manufacturing North America Market

North America holds a dominant position in the Smart Manufacturing Market. The U.S. is a leader in the adoption of smart manufacturing technologies, driven by strong industrial infrastructure, significant R&D investments, and government initiatives like the Advanced Manufacturing Partnership. The country is a hub for innovation in automation, IoT, and AI, with many companies adopting these technologies to enhance productivity and competitiveness.

Smart Manufacturing Asia-Pacific Market

The Asia-Pacific region has indeed emerged as the fastest-growing market for the Smart Manufacturing Market industry. The Asia-Pacific region holds the largest market share, driven by factors such as rapid industrialization, a large manufacturing base, and significant investments in technology. China is a rapidly growing market for smart manufacturing, driven by the government’s Made in China 2025 initiative, which aims to upgrade its manufacturing capabilities through the adoption of advanced technologies. Chinese manufacturers are increasingly investing in automation, robotics, and AI to improve efficiency and product quality and India’s smart manufacturing market is in a growth phase, supported by government initiatives like Make in India. The country is focusing on digitalization and automation to improve its manufacturing sector’s efficiency and global competitiveness, particularly in industries like automotive, textiles, and electronics.

Competitive Landscape

The global Smart Manufacturing Market is highly competitive, with numerous players offering a wide range of software solutions. The competitive landscape is characterized by the presence of established companies, as well as emerging startups and niche players. To increase their market position and attract a wide consumer base, the businesses are employing various strategies, such as product launches, and strategic alliances.

Prominent Players:

- Emerson

- Honeywell

- Rockwell

- ABB

- Schneider

- IBM

- General Electric

- Siemens

- Fanuc

- Yokogawa

Scope of the Report

Global Smart Manufacturing Market, by Information Technology

- Human-Machine Interface

- Plant Asset Management

- Manufacturing Execution System

- Others

Global Smart Manufacturing Market, by Enabling Technology

- Industrial 3D printing

- Collaborative robot

- IIOT

- AI in manufacturing

- Others

Global Smart Manufacturing Market, by Region

- North America

- US

- Canada

- Mexico

- Europe

- UK

- Germany

- France

- Italy

- Spain

- Benelux

- Nordic

- Rest of Europe

- Asia Pacific

- China

- Japan

- South Korea

- Indonesia

- Austalia

- Malaysia

- India

- Rest of Asia Pacific

- South America

- Brazil

- Argentina

- Rest of South America

- Middle East & Africa

- Saudi Arabia

- UAE

- Egypt

- South Africa

- Rest of Middle East & Africa

| Parameters | Indicators |

|---|---|

| Market Size | 2033: $321.14 Billion |

| CAGR | 14.52% CAGR (2023-2033) |

| Base year | 2022 |

| Forecast Period | 2023-2033 |

| Historical Data | 2021 |

| Report Coverage | Revenue Forecast, Competitive Landscape, Growth Factors, and Trends |

| Key Segmentations | Information Technology, Enabling Technology |

| Geographies Covered | North America, Europe, Asia-Pacific, Latin America, Middle East, Africa |

| Key Vendors | Emerson, Honeywell, Rockwell, ABB, Schneider, IBM, General Electric, Siemens, Fanuc and Yokogawa |

| Key Market Opportunities | • Adoption of Advanced Technologies |

| Key Market Drivers | • Industry 4.0 and Digital Transformation • Operational Efficiency and Cost Reduction |

REPORT CONTENT BRIEF:

- High-level analysis of the current and future Smart Manufacturing Market trends and opportunities

- Detailed analysis of current market drivers, restraining factors, and opportunities in the future

- Smart Manufacturing Market historical market size for the year 2021, and forecast from 2023 to 2033

- Smart Manufacturing Market share analysis at each product level

- Competitor analysis with detailed insight into its product segment, Government & Defense strength, and strategies adopted.

- Identifies key strategies adopted including product launches and developments, mergers and acquisitions, joint ventures, collaborations, and partnerships as well as funding taken and investment done, among others.

- To identify and understand the various factors involved in the global Smart Manufacturing Market affected by the pandemic

- To provide a detailed insight into the major companies operating in the market. The profiling will include the Government & Defense health of the company’s past 2-3 years with segmental and regional revenue breakup, product offering, recent developments, SWOT analysis, and key strategies.

Press Release

Global Pharmaceutical Manufacturing Market to Reach $1.38 Trillion by 2035 with 7.35% CAGR, New Research Shows

The Global Mammography Market Is Estimated To Record a CAGR of Around 10.29% During The Forecast Period

Glue Stick Market to Reach USD 2.35 Billion by 2034

Podiatry Service Market to Reach USD 11.88 Billion by 2034

Microfluidics Technology Market to Reach USD 32.58 Billion by 2034

Ferric Chloride Market to Reach USD 10.65 Billion by 2034

Family Practice EMR Software Market to Reach USD 21.52 Billion by 2034

Electric Hairbrush Market to Reach USD 15.95 Billion by 2034

Daily Bamboo Products Market to Reach USD 143.52 Billion by 2034

Cross-border E-commerce Logistics Market to Reach USD 112.65 Billion by 2034

Frequently Asked Questions (FAQ)

What is the study period of this market?

The study period of the global Smart Manufacturing Market is 2021- 2033

What is the growth rate of the global Smart Manufacturing Market?

The global Smart Manufacturing Market is growing at a CAGR of 14.52% over the next 10 years

Which region has the highest growth rate in the market of Smart Manufacturing Market?

Asia Pacific is expected to register the highest CAGR during 2023-2033

Which region has the largest share of the global Smart Manufacturing Market?

North America holds the largest share in 2022

Who are the key players in the global Smart Manufacturing Market?

Emerson, Honeywell, Rockwell, ABB, Schneider, IBM, General Electric, Siemens, Fanuc and Yokogawa are the major companies operating in the market

Do you offer Post Sale Support?

Yes, we offer 16 hours of analyst support to solve the queries

Do you sell particular sections of a report?

Yes, we provide regional as well as country-level reports. Other than this we also provide a sectional report. Please get in contact with our sales representatives

Table of Content

Chapter 1. Executive Summary Chapter 2. Scope Of The Study 2.1. Market Definition 2.2. Scope Of The Study 2.2.1. Objectives of Report Chapter 3. Evolve BI Methodology Chapter 4. Market Insights and Trends 4.1. Supply/ Value Chain Analysis 4.2. Porter’s Five Forces Analysis 4.2.1. Threat Of New Entrants 4.2.2. Bargaining Power Of Buyers 4.2.3. Bargaining Power Of Suppliers 4.2.4. Threat Of Substitutes 4.2.5. Industry Rivalry 4.3. Impact of COVID-19 on Smart Manufacturing Market 4.3.1. Impact on Market Size 4.3.2. End User Trend, Preferences and Budget Impact 4.3.3. Regulatory Framework/Government Policies 4.3.4. Key Players Strategy to Tackle Negative Impact 4.3.5. Opportunity Window Chapter 5. Market Dynamics 5.1. Introduction 5.2. DRO Analysis 5.2.1. Drivers 5.2.2. Restraints 5.2.3. Opportunities Chapter 6. Global Smart Manufacturing Market, By Information Technology 6.1. Introduction 6.2. Human-Machine Interface 6.3. Plant Asset Management 6.3. Manufacturing Execution System 6.4. Others Chapter 7. Global Smart Manufacturing Market, By Enabling Technology 7.1. Introduction 7.2. Industrial 3D printing 7.3. Collaborative robot 7.4. IIOT 7.5. AI in manufacturing 7.6. Others Chapter 8. Global Smart Manufacturing Market, By Region 8.1. Introduction 8.2. North America 8.2.1. Introduction 8.2.2. Driving Factors, Opportunity Analyzed and Key Trends 8.2.3. Market Size and Forecast, By Country, 2020 - 2028 8.2.4. Market Size and Forecast, By Information Technology, 2020 - 2028 8.2.5. Market Size and Forecast, By Enabling Technology, 2020 – 2028 8.2.6. US 8.2.6.1. Introduction 8.2.6.2. Driving Factors, Opportunity Analyzed and Key Trends 8.2.6.3. Market Size and Forecast, By Information Technology, 2020 - 2028 8.2.6.4. Market Size and Forecast, By Enabling Technology, 2020 - 2028 8.2.7. Canada 8.2.7.1. Introduction 8.2.7.2. Driving Factors, Opportunity Analyzed and Key Trends 8.2.7.3. Market Size and Forecast, By Information Technology, 2020 - 2028 8.2.7.4. Market Size and Forecast, By Enabling Technology, 2020 - 2028 8.3. Europe 8.3.1. Introduction 8.3.2. Driving Factors, Opportunity Analyzed and Key Trends 8.3.3. Market Size and Forecast, By Country, 2020 - 2028 8.3.4. Market Size and Forecast, By Information Technology, 2020 - 2028 8.3.5. Market Size and Forecast, By Enabling Technology, 2020 – 2028 8.3.6. Germany 8.3.6.1. Introduction 8.3.6.2. Driving Factors, Opportunity Analyzed and Key Trends 8.3.6.3. Market Size and Forecast, By Information Technology, 2020 - 2028 8.3.6.4. Market Size and Forecast, By Enabling Technology, 2020 - 2028 8.3.7. France 8.3.7.1. Introduction 8.3.7.2. Driving Factors, Opportunity Analyzed and Key Trends 8.3.7.3. Market Size and Forecast, By Information Technology, 2020 - 2028 8.3.7.4. Market Size and Forecast, By Enabling Technology, 2020 - 2028 8.3.8. UK 8.3.8.1. Introduction 8.3.8.2. Driving Factors, Opportunity Analyzed and Key Trends 8.3.8.3. Market Size and Forecast, By Information Technology, 2020 - 2028 8.3.8.4. Market Size and Forecast, By Enabling Technology, 2020 - 2028 8.3.9. Italy 8.3.9.1. Introduction 8.3.9.2. Driving Factors, Opportunity Analyzed and Key Trends 8.3.9.3. Market Size and Forecast, By Information Technology, 2020 - 2028 8.3.9.4. Market Size and Forecast, By Enabling Technology, 2020 - 2028 8.3.10. Rest Of Europe 8.3.10.1. Introduction 8.3.10.2. Driving Factors, Opportunity Analyzed and Key Trends 8.3.10.3. Market Size and Forecast, By Information Technology, 2020 - 2028 8.3.10.4. Market Size and Forecast, By Enabling Technology, 2020 - 2028 8.4. Asia-Pacific 8.4.1. Introduction 8.4.2. Driving Factors, Opportunity Analyzed and Key Trends 8.4.3. Market Size and Forecast, By Country, 2020 - 2028 8.4.4. Market Size and Forecast, By Information Technology, 2020 - 2028 8.4.5. Market Size and Forecast, By Enabling Technology, 2020 - 2028 8.4.6. China 8.4.6.1. Introduction 8.4.6.2. Driving Factors, Opportunity Analyzed and Key Trends 8.4.6.3. Market Size and Forecast, By Information Technology, 2020 - 2028 8.4.6.4. Market Size and Forecast, By Enabling Technology, 2020 - 2028 8.4.7. India 8.4.7.1. Introduction 8.4.7.2. Driving Factors, Opportunity Analyzed and Key Trends 8.4.7.3. Market Size and Forecast, By Information Technology, 2020 - 2028 8.4.7.4. Market Size and Forecast, By Enabling Technology, 2020 - 2028 8.4.8. Japan 8.4.8.1. Introduction 8.4.8.2. Driving Factors, Opportunity Analyzed and Key Trends 8.4.8.3. Market Size and Forecast, By Information Technology, 2020 - 2028 8.4.8.4. Market Size and Forecast, By Enabling Technology, 2020 - 2028 8.4.9. South Korea 8.4.9.1. Introduction 8.4.9.2. Driving Factors, Opportunity Analyzed and Key Trends 8.4.9.3. Market Size and Forecast, By Information Technology, 2020 - 2028 8.4.9.4. Market Size and Forecast, By Enabling Technology, 2020 - 2028 8.4.10. Rest Of Asia-Pacific 8.4.10.1. Introduction 8.4.10.2. Driving Factors, Opportunity Analyzed and Key Trends 8.4.10.3. Market Size and Forecast, By Information Technology, 2020 - 2028 8.4.10.4. Market Size and Forecast, By Enabling Technology, 2020 - 2028 8.5. Rest Of The World (RoW) 8.5.1. Introduction 8.5.2. Driving Factors, Opportunity Analyzed and Key Trends 8.5.3. Market Size and Forecast, By Information Technology, 2020 - 2028 8.5.4. Market Size and Forecast, By Enabling Technology, 2020 - 2028 8.5.5. Market Size and Forecast, By Region, 2020 - 2028 8.5.6. South America 8.5.6.1. Introduction 8.5.6.2. Driving Factors, Opportunity Analyzed and Key Trends 8.5.6.3. Market Size and Forecast, By Information Technology, 2020 - 2028 8.5.6.4. Market Size and Forecast, By Enabling Technology, 2020 - 2028 8.5.7. Middle East and Africa 8.5.7.1. Introduction 8.5.7.2. Driving Factors, Opportunity Analyzed and Key Trends 8.5.7.3. Market Size and Forecast, By Information Technology, 2020 - 2028 8.5.7.4. Market Size and Forecast, By Enabling Technology, 2020 - 2028 Chapter 9. Competitive Landscape 9.1. Introduction 9.2. Vendor Share Analysis, 2020/Key Players Positioning, 2020 Chapter 10. Company Profiles 10.1. Emerson 10.1.1. Business Overview 10.1.2. Financial Analysis 10.1.3. Product Portfolio 10.1.4. Recent Development and Strategies Adopted 10.1.5. SWOT Analysis 10.2. Honeywell 10.2.1. Business Overview 10.2.2. Financial Analysis 10.2.3. Product Portfolio 10.2.4. Recent Development and Strategies Adopted 10.2.5. SWOT Analysis 10.3. Rockwell 10.3.1. Business Overview 10.3.2. Financial Analysis 10.3.3. Product Portfolio 10.3.4. Recent Development and Strategies Adopted 10.3.5. SWOT Analysis 10.4. ABB 10.4.1. Business Overview 10.4.2. Financial Analysis 10.4.3. Product Portfolio 10.4.4. Recent Development and Strategies Adopted 10.4.5. SWOT Analysis 10.5. Schneider 10.5.1. Business Overview 10.5.2. Financial Analysis 10.5.3. Product Portfolio 10.5.4. Recent Development and Strategies Adopted 10.5.5. SWOT Analysis 10.6. IBM 10.6.1. Business Overview 10.6.2. Financial Analysis 10.6.3. Product Portfolio 10.6.4. Recent Development and Strategies Adopted 10.6.5. SWOT Analysis 10.7. General Electric 10.7.1. Business Overview 10.7.2. Financial Analysis 10.7.3. Product Portfolio 10.7.4. Recent Development and Strategies Adopted 10.7.5. SWOT Analysis 10.8. Siemens 10.8.1. Business Overview 10.8.2. Financial Analysis 10.8.3. Product Portfolio 10.8.4. Recent Development and Strategies Adopted 10.8.5. SWOT Analysis 10.9. Fanuc 10.9.1. Business Overview 10.9.2. Financial Analysis 10.9.3. Product Portfolio 10.9.4. Recent Development and Strategies Adopted 10.9.5. SWOT Analysis 10.10. Yokogawa 10.10.1. Business Overview 10.10.2. Financial Analysis 10.10.3. Product Portfolio 10.10.4. Recent Development and Strategies Adopted 10.10.5. SWOT Analysis Chapter 11. Key Takeaways

Connect to Analyst

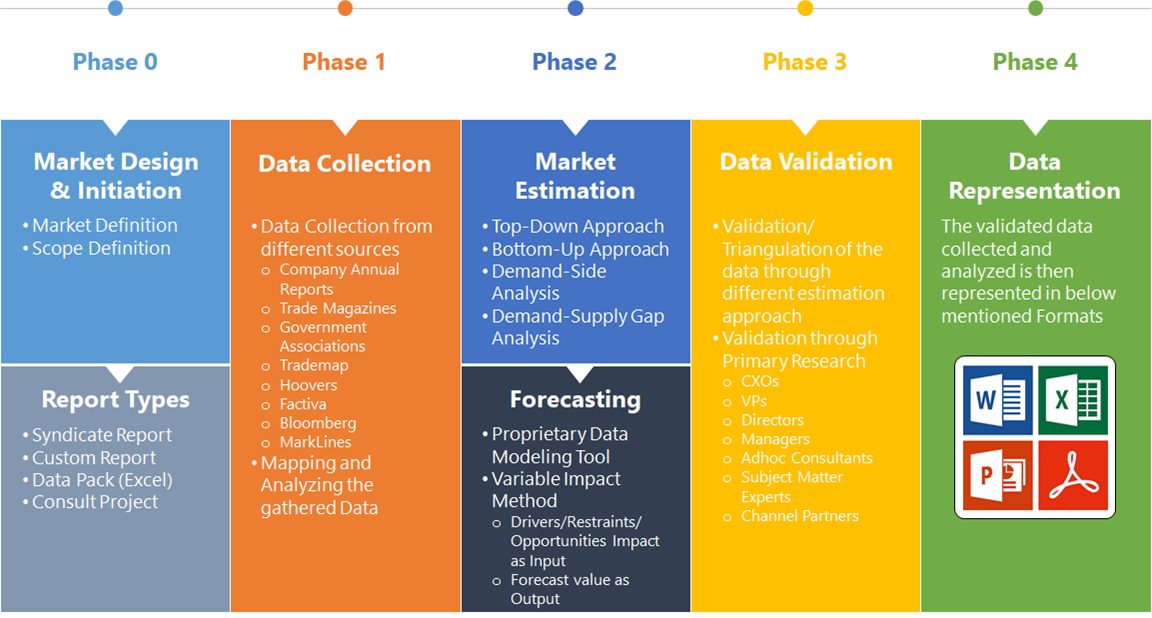

Research Methodology