Railway Maintenance Machinery Market Analysis and Global Forecast 2023-2033

€ 1,230.43 – € 4,886.30Price range: € 1,230.43 through € 4,886.30

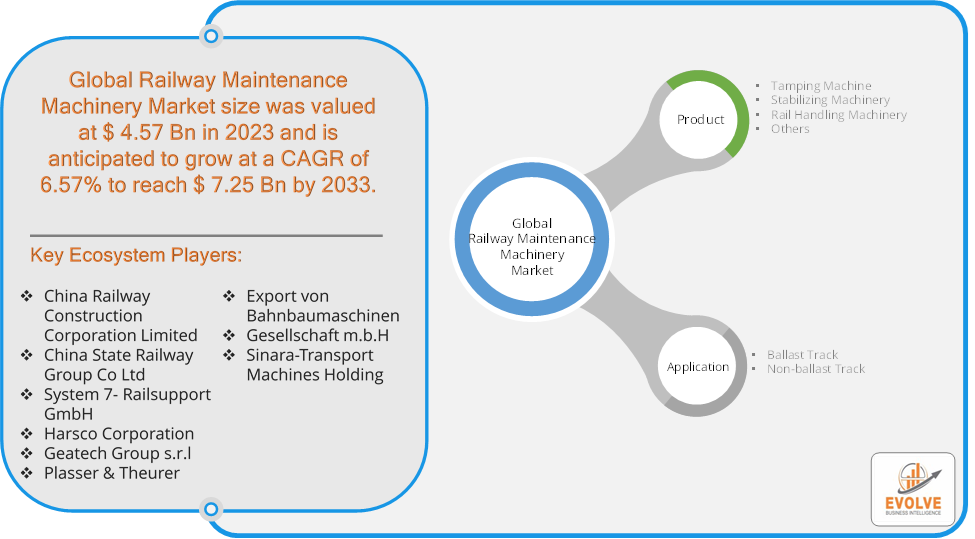

Railway Maintenance Machinery Market Research Report: Information By Product Type (Tamping Machine, Stabilizing Machinery, Rail Handling Machinery, Others), By Application (Ballast Track, Non-ballast Track), and by Region — Forecast till 2033

Page: 157

Railway Maintenance Machinery Market Overview

The Railway Maintenance Machinery Market Size is expected to reach USD 7.25 Billion by 2033. The Railway Maintenance Machinery Market industry size accounted for USD 4.57 Billion in 2023 and is expected to expand at a compound annual growth rate (CAGR) of 6.57% from 2023 to 2033. The Railway Maintenance Machinery Market refers to the global industry focused on the production, distribution, and servicing of machinery and equipment used for the maintenance and repair of railway infrastructure. This market encompasses a wide range of specialized machines designed for tasks such as track inspection, rail grinding, tamping, ballast cleaning, and more, ensuring the safe and efficient operation of rail networks.

The market is driven by factors such as the expansion of rail networks, increasing focus on safety and efficiency, technological advancements in machinery, and the growing need for automated and efficient maintenance solutions. It is also influenced by investments in high-speed rail and the modernization of existing railway infrastructure. Key players in the market include manufacturers of railway maintenance machinery, service providers, and suppliers of components and parts.

Global Railway Maintenance Machinery Market Synopsis

The COVID-19 pandemic had a significant impact on the Railway Maintenance Machinery Market. The pandemic caused widespread disruptions in global supply chains, affecting the production and delivery of railway maintenance machinery. Manufacturing facilities were forced to close or operate at reduced capacity, leading to delays in the production and shipment of machinery and components. With reduced rail traffic during the pandemic, many railway operators prioritized essential maintenance over new investments or non-essential upgrades. This led to a focus on maintaining existing infrastructure rather than expanding or modernizing, affecting the market for certain types of maintenance machinery. The pandemic slowed down research and development activities within the industry. Companies were forced to cut costs, which often meant reducing investments in innovation and the development of new technologies in railway maintenance machinery. The pandemic has led to strategic shifts in the railway industry, with increased emphasis on automation, remote monitoring, and predictive maintenance. This could drive future demand for advanced maintenance machinery, despite the initial setbacks caused by COVID-19.

Railway Maintenance Machinery Market Dynamics

The major factors that have impacted the growth of Railway Maintenance Machinery Market are as follows:

Drivers:

Ø Technological Advancements

The adoption of new technologies, such as automation, AI, and IoT, in railway maintenance machinery is transforming the industry. These advancements allow for more precise, efficient, and predictive maintenance, which reduces downtime and enhances the longevity of railway infrastructure. Rapid urbanization and the increasing reliance on public transportation systems are driving the expansion and maintenance of urban rail networks, such as subways, trams, and light rail. This trend is contributing to the growing demand for maintenance machinery in urban settings. The expansion of high-speed rail networks requires specialized maintenance to ensure the tracks and infrastructure can handle the high speeds safely. The growth of high-speed rail projects globally is driving demand for advanced maintenance machinery tailored to these needs.

Restraint:

- Perception of High Initial Costs

Railway maintenance machinery is typically expensive to purchase and install. The high upfront costs can be a significant barrier for railway operators, particularly in regions with limited budgets or smaller rail networks, making it challenging to justify the investment. The railway industry is often conservative in adopting new technologies due to concerns about reliability, safety, and the integration of new systems with existing infrastructure. This slow adoption can restrain market growth, particularly for advanced or automated machinery.

Opportunity:

⮚ Expansion of High-Speed Rail Networks

The global push towards high-speed rail networks is creating a demand for specialized maintenance machinery that can support the unique requirements of high-speed trains. Companies that develop advanced machinery for high-speed rail maintenance can capitalize on this growing market. The digital transformation of the railway industry opens up opportunities for smart maintenance solutions. By leveraging data analytics, machine learning, and real-time monitoring, companies can offer predictive maintenance services, reducing downtime and improving operational efficiency.

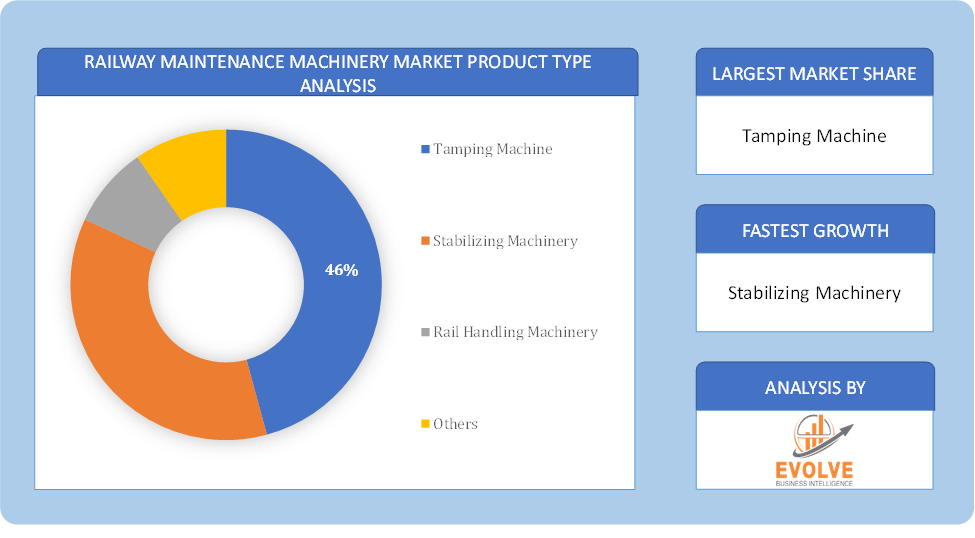

Railway Maintenance Machinery Market Segment Overview

Based on Product Type, the market is segmented based on Tamping Machine, Stabilizing Machinery, Rail Handling Machinery and Others. The tamping machine segment dominant the market. Tamping machines are cost-effective railway maintenance machinery that lessens track maintenance costs and improves the performance of railway tracks. Huge government spending on railway infrastructure projects globally is expected to drive the growth of this segment. Besides, the demand for tamping machines is anticipated to grow throughout the study period, owing to efforts to enhance safety, renovate the quality of current railway lines, and avoid railway accidents globally.

By Application

Based on Application, the market segment has been divided into Ballast Track and Non-ballast Track. The ballast track segment dominant the market. Ballast tracks are laid under railway sleepers to reduce the stress on the ground. Ballast track is generally adopted in the railway maintenance industry owing to features such as quick water drainage and chances of vegetation. Ballast tracks can be installed horizontally or vertically. The growth in several railways in addition to government initiatives to cut carbon emissions caters to the growth of the railway maintenance machinery market for ballast tracks.

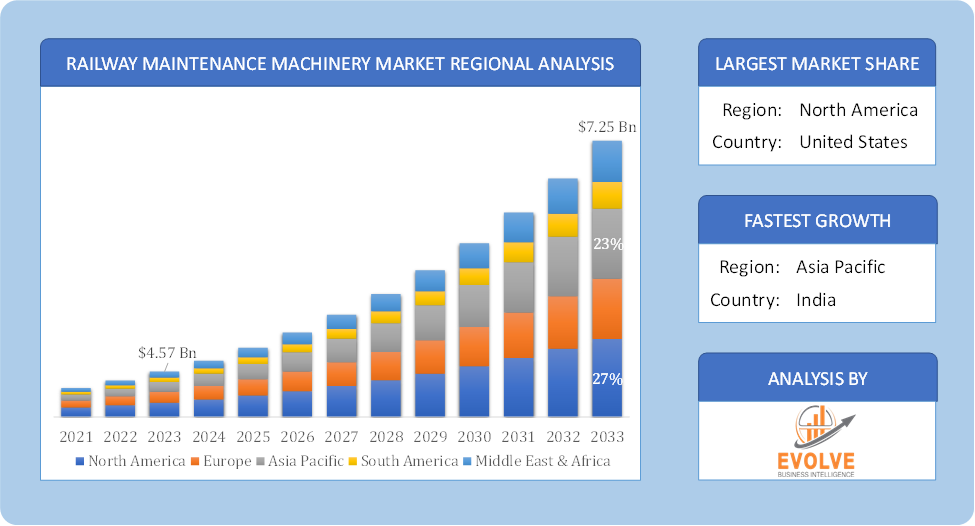

Global Railway Maintenance Machinery Market Regional Analysis

Based on region, the global Railway Maintenance Machinery Market has been divided into North America, Europe, Asia-Pacific, the Middle East & Africa, and Latin America. North America is projected to dominate the use of the Railway Maintenance Machinery Market followed by the Asia-Pacific and Europe regions.

Railway Maintenance Machinery North America Market

Railway Maintenance Machinery North America Market

North America holds a dominant position in the Railway Maintenance Machinery Market. North America has a well-established railway infrastructure, particularly in the U.S. and Canada. The region is focused on maintaining and upgrading its extensive freight rail network, which is one of the most advanced in the world and the focus on enhancing rail safety, increasing freight transportation, and government investments in infrastructure are key drivers in this region. The adoption of advanced technologies and automation in railway maintenance machinery is also growing.

Railway Maintenance Machinery Asia-Pacific Market

The Asia-Pacific region has indeed emerged as the fastest-growing market for the Railway Maintenance Machinery Market industry. Asia-Pacific is the fastest-growing region in the Railway Maintenance Machinery Market, driven by rapid urbanization, economic growth, and significant investments in rail infrastructure, particularly in China, India, and Southeast Asia and the region presents vast opportunities for new machinery sales, particularly in emerging economies investing in rail infrastructure. There’s also potential in automation and advanced maintenance technologies, as well as in meeting the growing demand for rail transport in densely populated urban areas.

Competitive Landscape

The global Railway Maintenance Machinery Market is highly competitive, with numerous players offering a wide range of software solutions. The competitive landscape is characterized by the presence of established companies, as well as emerging startups and niche players. To increase their market position and attract a wide consumer base, the businesses are employing various strategies, such as product launches, and strategic alliances.

Prominent Players:

- China Railway Construction Corporation Limited

- China State Railway Group Co Ltd

- System 7- Railsupport GmbH

- Harsco Corporation

- Geatech Group s.r.l

- Plasser & Theurer

- Export von Bahnbaumaschinen

- Gesellschaft m.b.H

- Sinara-Transport Machines Holding

Key Development

In May 2021, Jinzhou Tiegong Railway Maintenance Machinery Co., Ltd. launched DG550 electric rail tamper which is apt for tamping ballast bed in railway line maintenance and overhaul.

In January 2021, Sinara Transport Machines Holding introduced a new RTM-32 track tamper machine for railway projects in India. This machine is operated on both electrical and mechanical components. This tamping machine is used in IR (Indian railway) industry. It uses components such as cranes, ballast regulating machines, and tampers.

Scope of the Report

Global Railway Maintenance Machinery Market, by Product Type

- Tamping Machine

- Stabilizing Machinery

- Rail Handling Machinery

- Others

Global Railway Maintenance Machinery Market, by Application

- Ballast Track

- Non-ballast Track

Global Railway Maintenance Machinery Market, by Region

- North America

- US

- Canada

- Mexico

- Europe

- UK

- Germany

- France

- Italy

- Spain

- Benelux

- Nordic

- Rest of Europe

- Asia Pacific

- China

- Japan

- South Korea

- Indonesia

- Austalia

- Malaysia

- India

- Rest of Asia Pacific

- South America

- Brazil

- Argentina

- Rest of South America

- Middle East & Africa

- Saudi Arabia

- UAE

- Egypt

- South Africa

- Rest of Middle East & Africa

| Parameters | Indicators |

|---|---|

| Market Size | 2033: USD 7.25 Billion |

| CAGR (2023-2033) | 6.57% |

| Base year | 2022 |

| Forecast Period | 2023-2033 |

| Historical Data | 2021 (2017 to 2020 On Demand) |

| Report Coverage | Revenue Forecast, Competitive Landscape, Growth Factors, and Trends |

| Key Segmentations | Product Type, Application |

| Geographies Covered | North America, Europe, Asia-Pacific, South America, Middle East, Africa |

| Key Vendors | China Railway Construction Corporation Limited, China State Railway Group Co Ltd, System 7- Railsupport GmbH, Harsco Corporation, Geatech Group s.r.l, Plasser & Theurer, Export von Bahnbaumaschinen, Gesellschaft m.b.H and Sinara-Transport Machines Holding. |

| Key Market Opportunities | · Expansion of High-Speed Rail Networks · Digitalization and Smart Maintenance |

| Key Market Drivers | · Technological Advancements · Urbanization and Public Transportation Growth |

REPORT CONTENT BRIEF:

- High-level analysis of the current and future Railway Maintenance Machinery Market trends and opportunities

- Detailed analysis of current market drivers, restraining factors, and opportunities in the future

- Railway Maintenance Machinery Market historical market size for the year 2021, and forecast from 2023 to 2033

- Railway Maintenance Machinery Market share analysis at each product level

- Competitor analysis with detailed insight into its product segment, Government & Defense strength, and strategies adopted.

- Identifies key strategies adopted including product launches and developments, mergers and acquisitions, joint ventures, collaborations, and partnerships as well as funding taken and investment done, among others.

- To identify and understand the various factors involved in the global Railway Maintenance Machinery Market affected by the pandemic

- To provide a detailed insight into the major companies operating in the market. The profiling will include the Government & Defense health of the company’s past 2-3 years with segmental and regional revenue breakup, product offering, recent developments, SWOT analysis, and key strategies.

Frequently Asked Questions (FAQ)

What is the study period of this market?

The study period of the global Railway Maintenance Machinery Market is 2021- 2033

What is the growth rate of the global Railway Maintenance Machinery Market?

The global Railway Maintenance Machinery Market is growing at a CAGR of 6.57% over the next 10 years

Which region has the highest growth rate in the market of Railway Maintenance Machinery Market?

Asia Pacific is expected to register the highest CAGR during 2023-2033

Which region has the largest share of the global Railway Maintenance Machinery Market?

North America holds the largest share in 2022

Who are the key players in the global Railway Maintenance Machinery Market?

China Railway Construction Corporation Limited, China State Railway Group Co Ltd, System 7- Railsupport GmbH, Harsco Corporation, Geatech Group s.r.l, Plasser & Theurer, Export von Bahnbaumaschinen, Gesellschaft m.b.H and Sinara-Transport Machines Holding are the major companies operating in the market.

Do you offer Post Sale Support?

Yes, we offer 16 hours of analyst support to solve the queries

Do you sell particular sections of a report?

Yes, we provide regional as well as country-level reports. Other than this we also provide a sectional report. Please get in contact with our sales representatives.

Press Release

Global Pharmaceutical Manufacturing Market to Reach $1.38 Trillion by 2035 with 7.35% CAGR, New Research Shows

The Global Mammography Market Is Estimated To Record a CAGR of Around 10.29% During The Forecast Period

Glue Stick Market to Reach USD 2.35 Billion by 2034

Podiatry Service Market to Reach USD 11.88 Billion by 2034

Microfluidics Technology Market to Reach USD 32.58 Billion by 2034

Ferric Chloride Market to Reach USD 10.65 Billion by 2034

Family Practice EMR Software Market to Reach USD 21.52 Billion by 2034

Electric Hairbrush Market to Reach USD 15.95 Billion by 2034

Daily Bamboo Products Market to Reach USD 143.52 Billion by 2034

Cross-border E-commerce Logistics Market to Reach USD 112.65 Billion by 2034

Table of Content

Chapter 1. Executive Summary Chapter 2. Scope Of The Study 2.1. Market Definition 2.2. Scope Of The Study 2.2.1. Objectives of Report 2.2.2. Limitations 2.3. Market Structure Chapter 3. Evolve BI Methodology Chapter 4. Market Insights and Trends 4.1. Supply/ Value Chain Analysis 4.1.1. Raw End Users Providers 4.1.2. Manufacturing Process 4.1.3. Distributors/Retailers 4.1.4. End-Use Industry 4.2. Porter’s Five Forces Analysis 4.2.1. Threat Of New Entrants 4.2.2. Bargaining Power Of Buyers 4.2.3. Bargaining Power Of Suppliers 4.2.4. Threat Of Substitutes 4.2.5. Industry Rivalry 4.3. Impact Of COVID-19 on the Railway Maintenance Machinery Market 4.3.1. Impact on Market Size 4.3.2. End-Use Industry Trend, Preferences, and Budget Impact 4.3.3. Regulatory Framework/Government Policies 4.3.4. Key Players' Strategy to Tackle Negative Impact 4.3.5. Opportunity Window 4.4. Technology Overview 12.28. Macro factor 4.6. Micro Factor 4.7. Demand Supply Gap Analysis of the Railway Maintenance Machinery Market 4.8. Import Analysis of the Railway Maintenance Machinery Market 4.9. Export Analysis of the Railway Maintenance Machinery Market Chapter 5. Market Dynamics 5.1. Introduction 5.2. DROC Analysis 5.2.1. Drivers 5.2.2. Restraints 5.2.3. Opportunities 5.2.4. Challenges 5.3. Patent Analysis 5.4. Industry Roadmap 5.5. Parent/Peer Market Analysis Chapter 6. Global Railway Maintenance Machinery Market, By Product Type 6.1. Introduction 6.2. Tamping Machine 6.3. Stabilizing Machinery 6.4. Rail Handling Machinery 6.5. Others Chapter 7. Global Railway Maintenance Machinery Market, By Application 7.1. Introduction 7.2. Ballast Track 7.3. Non-ballast Track Chapter 8. Global Railway Maintenance Machinery Market, By Region 8.1. Introduction 8.2. North America 8.2.1. Introduction 8.2.2. Driving Factors, Opportunity Analyzed, and Key Trends 8.2.3. Market Size and Forecast, By Country, 2023-2033 8.2.4. Market Size and Forecast, By Product Type, 2023-2033 8.2.5. Market Size and Forecast, By End User, 2023-2033 8.2.6. US 8.2.6.1. Introduction 8.2.6.2. Driving Factors, Opportunity Analyzed, and Key Trends 8.2.6.3. Market Size and Forecast, By Product Type, 2023-2033 8.2.6.4. Market Size and Forecast, By End User, 2023-2033 8.2.7. Canada 8.2.7.1. Introduction 8.2.7.2. Driving Factors, Opportunity Analyzed, and Key Trends 8.2.7.4. Market Size and Forecast, By Product Type, 2023-2033 8.2.7.5. Market Size and Forecast, By End User, 2023-2033 8.3. Europe 8.3.1. Introduction 8.3.2. Driving Factors, Opportunity Analyzed, and Key Trends 8.3.3. Market Size and Forecast, By Country, 2023-2033 8.3.4. Market Size and Forecast, By Product Type, 2023-2033 8.3.5. Market Size and Forecast, By End User, 2023-2033 8.3.6. Germany 8.3.6.1. Introduction 8.3.6.2. Driving Factors, Opportunity Analyzed, and Key Trends 8.3.6.3. Market Size and Forecast, By Product Type, 2023-2033 8.3.6.4. Market Size and Forecast, By End User, 2023-2033 8.3.7. France 8.3.7.1. Introduction 8.3.7.2. Driving Factors, Opportunity Analyzed, and Key Trends 8.3.7.3. Market Size and Forecast, By Product Type, 2023-2033 8.3.7.4. Market Size and Forecast, By End User, 2023-2033 8.3.8. UK 8.3.8.1. Introduction 8.3.8.2. Driving Factors, Opportunity Analyzed, and Key Trends 8.3.8.3. Market Size and Forecast, By Product Type, 2023-2033 8.3.8.4. Market Size and Forecast, By End User, 2023-2033 8.3.9. Italy 8.3.9.1. Introduction 8.3.9.2. Driving Factors, Opportunity Analyzed, and Key Trends 8.3.9.3. Market Size and Forecast, By Product Type, 2023-2033 8.3.9.4. Market Size and Forecast, By End User, 2023-2033 8.3.11. Rest Of Europe 8.3.11.1. Introduction 8.3.11.2. Driving Factors, Opportunity Analyzed, and Key Trends 8.3.11.3. Market Size and Forecast, By Product Type, 2023-2033 8.3.11.4. Market Size and Forecast, By End User, 2023-2033 8.4. Asia-Pacific 8.4.1. Introduction 8.4.2. Driving Factors, Opportunity Analyzed, and Key Trends 8.4.3. Market Size and Forecast, By Country, 2023-2033 8.4.4. Market Size and Forecast, By Product Type, 2023-2033 8.12.28. Market Size and Forecast, By End User, 2023-2033 8.4.6. China 8.4.6.1. Introduction 8.4.6.2. Driving Factors, Opportunity Analyzed, and Key Trends 8.4.6.3. Market Size and Forecast, By Product Type, 2023-2033 8.4.6.4. Market Size and Forecast, By End User, 2023-2033 8.4.7. India 8.4.7.1. Introduction 8.4.7.2. Driving Factors, Opportunity Analyzed, and Key Trends 8.4.7.3. Market Size and Forecast, By Product Type, 2023-2033 8.4.7.4. Market Size and Forecast, By End User, 2023-2033 8.4.8. Japan 8.4.8.1. Introduction 8.4.8.2. Driving Factors, Opportunity Analyzed, and Key Trends 8.4.8.3. Market Size and Forecast, By Product Type, 2023-2033 8.4.8.4. Market Size and Forecast, By End User, 2023-2033 8.4.9. South Korea 8.4.9.1. Introduction 8.4.9.2. Driving Factors, Opportunity Analyzed, and Key Trends 8.4.9.3. Market Size and Forecast, By Product Type, 2023-2033 8.4.9.4. Market Size and Forecast, By End User, 2023-2033 8.4.10. Rest Of Asia-Pacific 8.4.10.1. Introduction 8.4.10.2. Driving Factors, Opportunity Analyzed, and Key Trends 8.4.10.3. Market Size and Forecast, By Product Type, 2023-2033 8.4.10.4. Market Size and Forecast, By End User, 2023-2033 8.5. Rest Of The World (RoW) 8.5.1. Introduction 8.5.2. Driving Factors, Opportunity Analyzed, and Key Trends 8.5.3. Market Size and Forecast, By Product Type, 2023-2033 8.5.4. Market Size and Forecast, By End User, 2023-2033 Chapter 9. Company Landscape 9.1. Introduction 9.2. Vendor Share Analysis 9.3. Key Development Analysis 9.4. Competitor Dashboard Chapter 10. Company Profiles 10.1. China Railway Construction Corporation Limited 10.1.1. Business Overview 10.1.2. Government & Defense Analysis 10.1.2.1. Government & Defense – Existing/Funding 10.1.3. Product Portfolio 10.1.4. Recent Development and Strategies Adopted 10.1.5. SWOT Analysis 10.2. China State Railway Group Co Ltd 10.2.1. Business Overview 10.2.2. Government & Defense Analysis 10.2.2.1. Government & Defense – Existing/Funding 10.2.3. Product Portfolio 10.2.4. Recent Development and Strategies Adopted 10.2.5. SWOT Analysis 10.3. System 7- Railsupport GmbH 10.3.1. Business Overview 10.3.2. Government & Defense Analysis 10.3.2.1. Government & Defense – Existing/Funding 10.3.3. Product Portfolio 10.3.4. Recent Development and Strategies Adopted 10.3.5. SWOT Analysis 10.4. Harsco Corporation 10.4.1. Business Overview 10.4.2. Government & Defense Analysis 10.4.2.1. Government & Defense – Existing/Funding 10.4.3. Product Portfolio 10.4.4. Recent Development and Strategies Adopted 10.12.28. SWOT Analysis 10.5. Geatech Group s.r.l 10.5.1. Business Overview 10.5.2. Government & Defense Analysis 10.5.2.1. Government & Defense – Existing/Funding 10.5.3. Product Portfolio 10.5.4. Recent Development and Strategies Adopted 10.5.5. SWOT Analysis 10.6. Plasser & Theurer 10.6.1. Business Overview 10.6.2. Government & Defense Analysis 10.6.2.1. Government & Defense – Existing/Funding 10.6.3. Product Portfolio 10.6.4. Recent Development and Strategies Adopted 10.6.5. SWOT Analysis 10.7. Export von Bahnbaumaschinen 10.7.1. Business Overview 10.7.2. Government & Defense Analysis 10.7.2.1. Government & Defense – Existing/Funding 10.7.3. Product Portfolio 10.7.4. Recent Development and Strategies Adopted 10.7.5. SWOT Analysis 10.8 Gesellschaft m.b.H 10.8.1. Business Overview 10.8.2. Government & Defense Analysis 10.8.2.1. Government & Defense – Existing/Funding 10.8.3. Product Portfolio 10.8.4. Recent Development and Strategies Adopted 10.8.5. SWOT Analysis 10.9 Sinara-Transport Machines Holding 10.9.1. Business Overview 10.9.2. Government & Defense Analysis 10.9.2.1. Government & Defense – Existing/Funding 10.9.3. Product Portfolio 10.9.4. Recent Development and Strategies Adopted 10.9.5. SWOT Analysis

Connect to Analyst

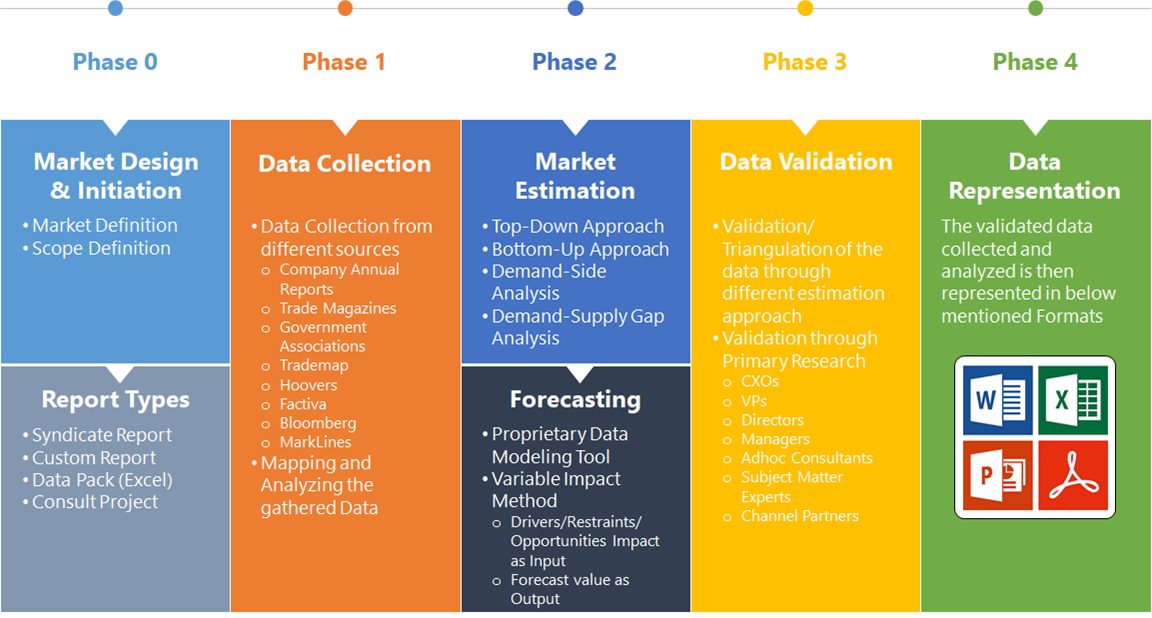

Research Methodology