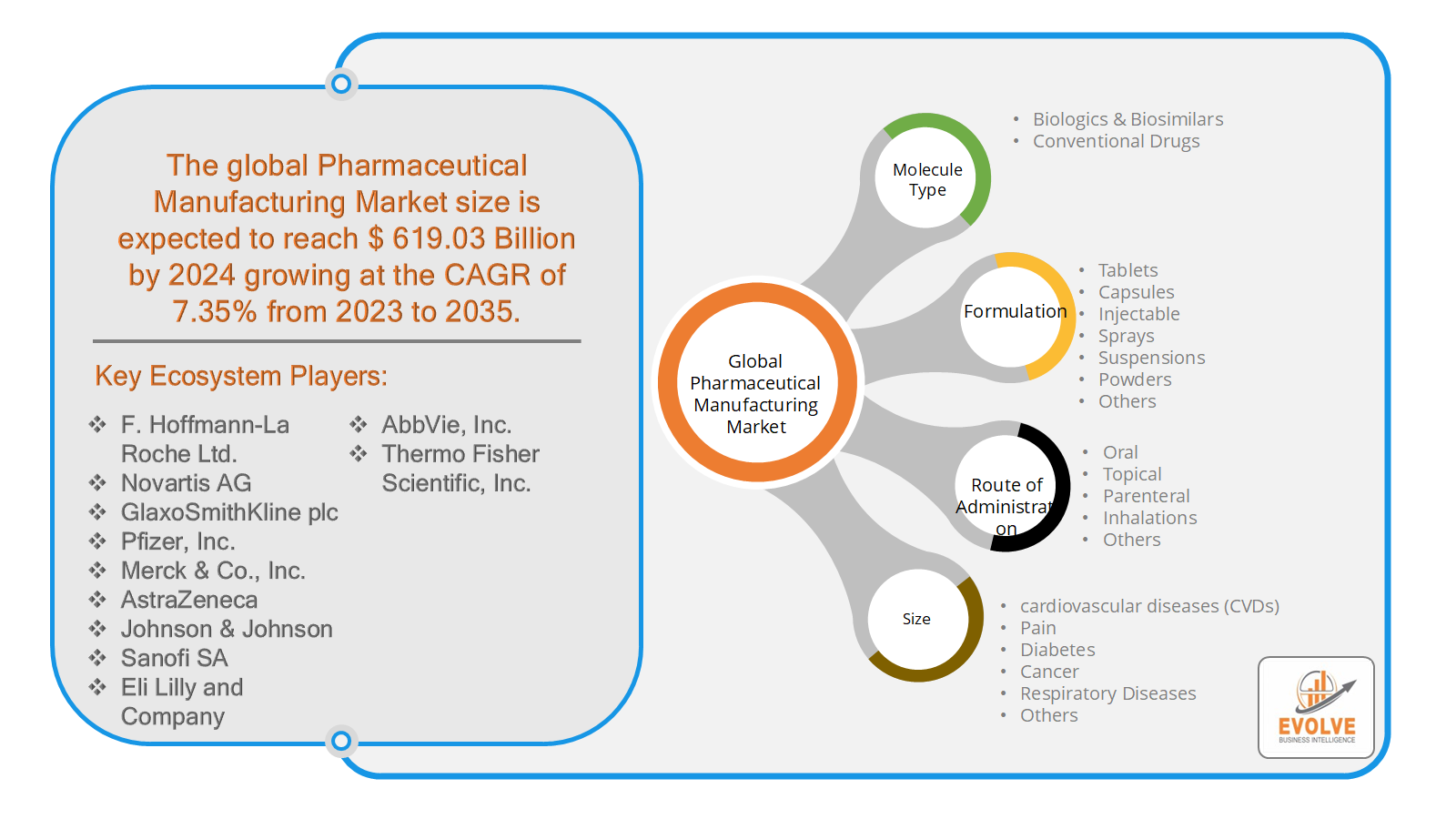

Pharmaceutical Manufacturing Market Overview

The Pharmaceutical Manufacturing Market size accounted for USD 562.35 Billion in 2023 and is estimated to account for 619.03 Billion in 2024. The Market is expected to reach USD 1379.59 Billion by 2035 growing at a compound annual growth rate (CAGR) of 31.75% from 2024 to 2035. The Pharmaceutical Manufacturing Market refers to the industry involved in the production of medications, including prescription and over-the-counter drugs, through chemical synthesis, fermentation, or biotechnological processes. This market plays a critical role in global healthcare by supplying drugs needed to prevent, treat, or manage various health conditions.

The pharmaceutical manufacturing market is a dynamic and expanding industry driven by increasing healthcare needs, technological advancements, and a growing focus on innovative treatments. The market presents numerous opportunities for growth across various segments and regions, with a continuous evolution in manufacturing processes and therapeutic focus.

Global Pharmaceutical Manufacturing Market Synopsis

Pharmaceutical Manufacturing Market Dynamics

Pharmaceutical Manufacturing Market Dynamics

The major factors that have impacted the growth of Pharmaceutical Manufacturing Market are as follows:

Drivers:

- Rising Prevalence of Chronic Diseases and Aging Global Population

Increasing rates of conditions such as cancer, diabetes, cardiovascular diseases, and autoimmune disorders are driving demand for both generic and innovative pharmaceuticals. Older adults typically require more medications due to age-related health issues, leading to a surge in pharmaceutical consumption and manufacturing needs. Implementation of AI, IoT, continuous manufacturing, and automation improves production efficiency, reduces cost, and enhances product quality. Pharmaceutical companies are increasingly outsourcing manufacturing to Contract Development and Manufacturing Organizations (CDMOs) to reduce costs and time-to-market.

Restraint:

- High Capital Investment

Establishing pharmaceutical manufacturing facilities, especially for biologics, requires significant upfront investment in infrastructure, equipment, and skilled labor. Events like pandemics, geopolitical conflicts, and raw material shortages can severely affect drug production and distribution. The industry requires highly skilled professionals in areas like bioprocessing, GMP compliance, and quality assurance—positions that are often hard to fill and government cost-control measures, especially in public healthcare systems, and pressure from insurance providers reduce profit margins for manufacturers.

Opportunity:

⮚ Adoption of Advanced Manufacturing Technologies

Technologies such as continuous manufacturing, 3D printing, AI-driven automation, and single-use systems are transforming drug production—improving efficiency and scalability. The pandemic highlighted the importance of vaccine manufacturing. Ongoing efforts in pandemic preparedness and rising awareness of preventive care are creating long-term demand. The integration of IoT, AI, and data analytics into manufacturing operations (known as Pharma 4.0) offers opportunities for real-time monitoring, predictive maintenance, and improved compliance.

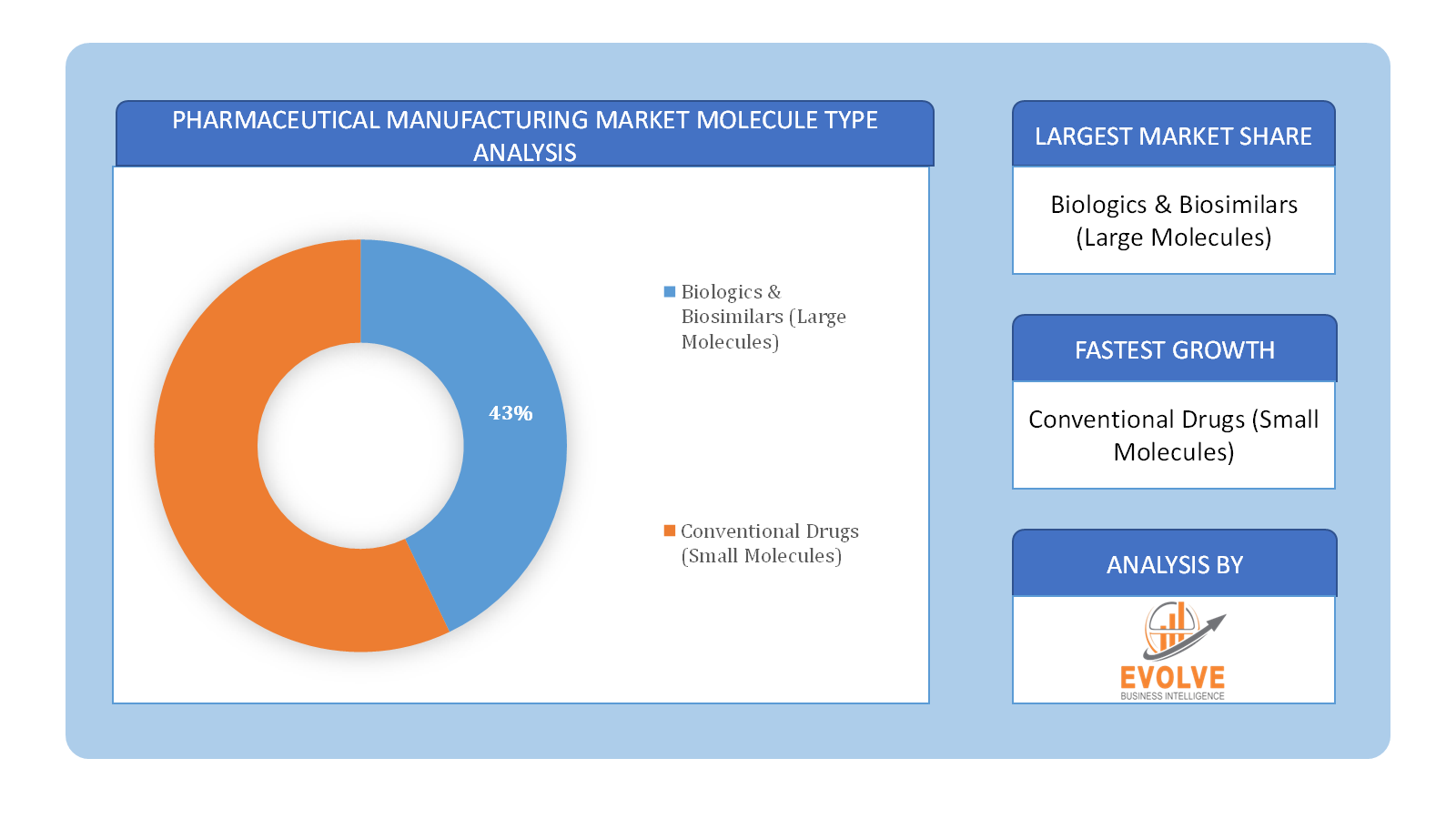

Pharmaceutical Manufacturing Market Segment Overview

Based on Molecule Type, the market is segmented based on Biologics & Biosimilars and Conventional Drugs. The Conventional Drugs segment dominant the market. The Conventional Drugs segment in pharmaceutical manufacturing refers to small-molecule medications that are chemically synthesized and widely used for treating a broad range of diseases. These drugs include tablets, capsules, injectables, and topical formulations, covering therapeutic areas such as cardiovascular diseases, infections, pain management, and neurological disorders.

By Formulation

Based on Formulation, the market segment has been divided into Tablets, Capsules, Injectable, Sprays, Suspensions, Powders, Others. The Tablets segment dominant the market. The Tablets segment refers to a solid dosage form in which active pharmaceutical ingredients (APIs) and excipients are compressed into a defined shape, typically for oral administration. Tablets are one of the most common and widely used drug formulations due to their stability, precise dosing, ease of storage, and patient convenience. They can be manufactured in various types, including immediate-release, extended-release, chewable, sublingual, and effervescent tablets, depending on the intended drug delivery mechanism.

By Route Of Administration

Based on Route Of Administration, the market segment has been divided into Oral, Topical, Parenteral, Inhalations, Others. The Oral segment dominant the market. The oral route of administration refers to the process of delivering medication through the mouth. This is the most common and convenient method of drug delivery, where the drug is formulated in forms such as tablets, capsules, liquids, suspensions, or powders that are ingested by the patient. Once consumed, the drug is absorbed through the gastrointestinal (GI) tract and enters the bloodstream to exert its therapeutic effect. Oral medications are typically preferred for their ease of use, non-invasive nature, and ability to be self-administered by patients.

By Therapy Area

Based on Therapy Area, the market segment has been divided into cardiovascular diseases (CVDs), Pain, Diabetes, Cancer, Respiratory Diseases, Others. The Respiratory Diseases segment dominant the market. Respiratory Diseases as a therapy area involves the development of medications to treat conditions affecting the lungs and airways, such as asthma, chronic obstructive pulmonary disease (COPD), chronic bronchitis, emphysema, and pulmonary infections. Medications in this category include bronchodilators, anti-inflammatory drugs, steroids, leukotriene modifiers, and antibiotics for infections. Inhalers (metered-dose inhalers (MDIs), dry powder inhalers (DPIs)), and nebulizers are commonly used for the direct delivery of drugs to the lungs, providing quick relief for conditions like asthma.

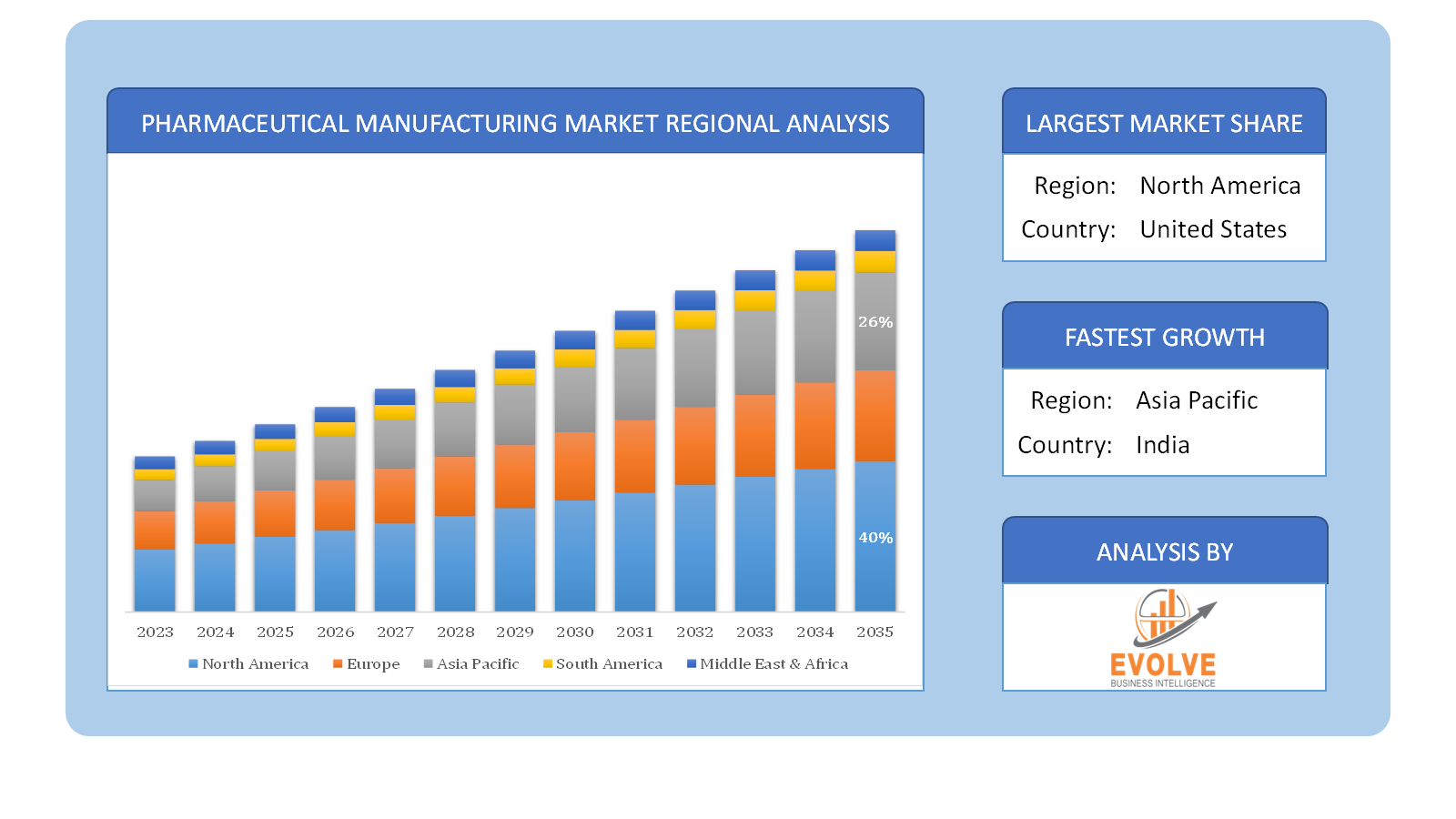

Global Pharmaceutical Manufacturing Market Regional Analysis

Based on region, the global Pharmaceutical Manufacturing Market has been divided into North America, Europe, Asia-Pacific, the Middle East & Africa, and Latin America. North America is projected to dominate the use of the Pharmaceutical Manufacturing Market followed by the Asia-Pacific and Europe regions.

North America Market

North America Market

North America is a key region in the Pharmaceutical Manufacturing Market. The pharmaceutical manufacturing market in North America is a highly advanced and competitive sector, driven by strong R&D investments, a well-established regulatory framework, and the presence of major global pharmaceutical companies. The United States dominates the regional market, accounting for the largest share due to its extensive biotech and pharmaceutical ecosystem, supported by the FDA’s stringent approval processes. Canada also contributes significantly, benefiting from favorable government policies and growing investments in drug production.

Asia-Pacific Market

The Asia-Pacific region has indeed emerged as the fastest-growing market for the Pharmaceutical Manufacturing Market industry. The pharmaceutical manufacturing market in the Asia-Pacific region is experiencing rapid growth, driven by increasing healthcare demand, government support, and expanding production capabilities. Countries such as China, India, and Japan are key players, with China and India emerging as global pharmaceutical manufacturing hubs due to their cost-effective production, skilled workforce, and strong generic drug industries. Japan, on the other hand, focuses on high-quality drug innovation and advanced biopharmaceuticals.

Competitive Landscape

The global Pharmaceutical Manufacturing Market is highly competitive, with numerous players offering a wide range of software solutions. The competitive landscape is characterized by the presence of established companies, as well as emerging startups and niche players. To increase their market position and attract a wide consumer base, the businesses are employing various strategies, such as product launches, and strategic alliances.

Prominent Players:

- Hoffmann-La Roche Ltd.

- Novartis AG

- GlaxoSmithKline plc

- Pfizer Inc.

- Merck & Co. Inc.

- AstraZeneca

- Johnson & Johnson

- Sanofi SA

- Eli Lilly and Company

- Thermo Fisher Scientific Inc.

Scope of the Report

Global Pharmaceutical Manufacturing Market, by Molecule Type

- Biologics & Biosimilars

- Conventional Drugs

Global Pharmaceutical Manufacturing Market, by Formulation

- Tablets

- Capsules

- Injectable

- Sprays

- Suspensions

- Powders

- Others

Global Pharmaceutical Manufacturing Market, by Route Of Administration

- Oral

- Topical

- Parenteral

- Inhalations

- Others

Global Pharmaceutical Manufacturing Market, by Therapy Area

- cardiovascular diseases (CVDs)

- Pain

- Diabetes

- Cancer

- Respiratory Diseases

- Others

Global Pharmaceutical Manufacturing Market, by Region

- North America

- US

- Canada

- Mexico

- Europe

- UK

- Germany

- France

- Italy

- Spain

- Benelux

- Nordic

- Rest of Europe

- Asia Pacific

- China

- Japan

- South Korea

- Indonesia

- Austalia

- Malaysia

- India

- Rest of Asia Pacific

- South America

- Brazil

- Argentina

- Rest of South America

- Middle East & Africa

- Saudi Arabia

- UAE

- Egypt

- South Africa

- Rest of Middle East & Africa

| Parameters | Indicators |

|---|---|

| Market Size | 2035: USD 1379.59 Billion |

| CAGR (2024-2034) | 7.35% |

| Base year | 2022 |

| Forecast Period | 2024-2035 |

| Historical Data | 2021 (2017 to 2020 On Demand) |

| Re-port Coverage | Revenue Forecast, Competitive Landscape, Growth Factors, and Trends |

| Key Segmentations | Molecule Type, Formulation, Route Of Administration, Therapy Area |

| Geographies Covered | North America, Europe, Asia-Pacific, South America, Middle East, Africa |

| Key Vendors | BASF SE, Akzo Nobel N.V., Axalta Coating Systems, Jotun, PPG Industries Inc, The Sherwin-Williams Company, Nippon Paint Holdings Co. Ltd., Hempel A/S, RPM International Inc., Diamond Paints and Kansai Paints. |

| Key Market Opportunities |

· Adoption of Advanced Manufacturing Technologies · Growth in Preventive Healthcare and Vaccines |

| Key Market Drivers |

· Rising Prevalence of Chronic Diseases and Aging Global Population · Advancements in Technology |

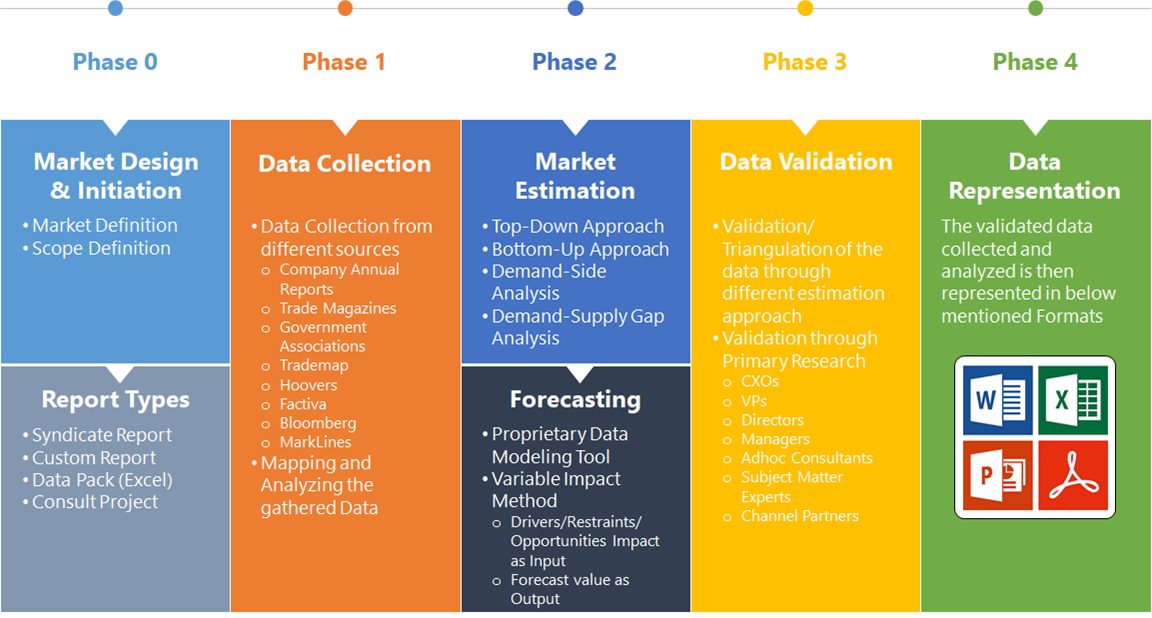

REPORT CONTENT BRIEF:

- High-level analysis of the current and future Pharmaceutical Manufacturing Market trends and opportunities

- Detailed analysis of current market drivers, restraining factors, and opportunities in the future

- Pharmaceutical Manufacturing Market historical market size for the year 2021, and forecast from 2023 to 2033

- Pharmaceutical Manufacturing Market share analysis at each product level

- Competitor analysis with detailed insight into its product segment, Government & Defense strength, and strategies adopted.

- Identifies key strategies adopted including product launches and developments, mergers and acquisitions, joint ventures, collaborations, and partnerships as well as funding taken and investment done, among others.

- To identify and understand the various factors involved in the global Pharmaceutical Manufacturing Market affected by the pandemic

- To provide a detailed insight into the major companies operating in the market. The profiling will include the Government & Defense health of the company’s past 2-3 years with segmental and regional revenue breakup, product offering, recent developments, SWOT analysis, and key strategies.