Machine Safety Market Analysis and Global Forecast 2023-2033

$ 1,390.00 – $ 5,520.00Price range: $ 1,390.00 through $ 5,520.00

Machine Safety Market Research Report: Information By Component (Safety Sensors, On-Safety Interlock Switches, Safety Controller, and Others), By Implementation (Individual, Embedded), By Industry Vertical (Oil and Gas, Healthcare, Automotive, Metals and Mining, and Other Industry Verticals) and By Region — Forecast till 2033

Machine Safety Market Overview

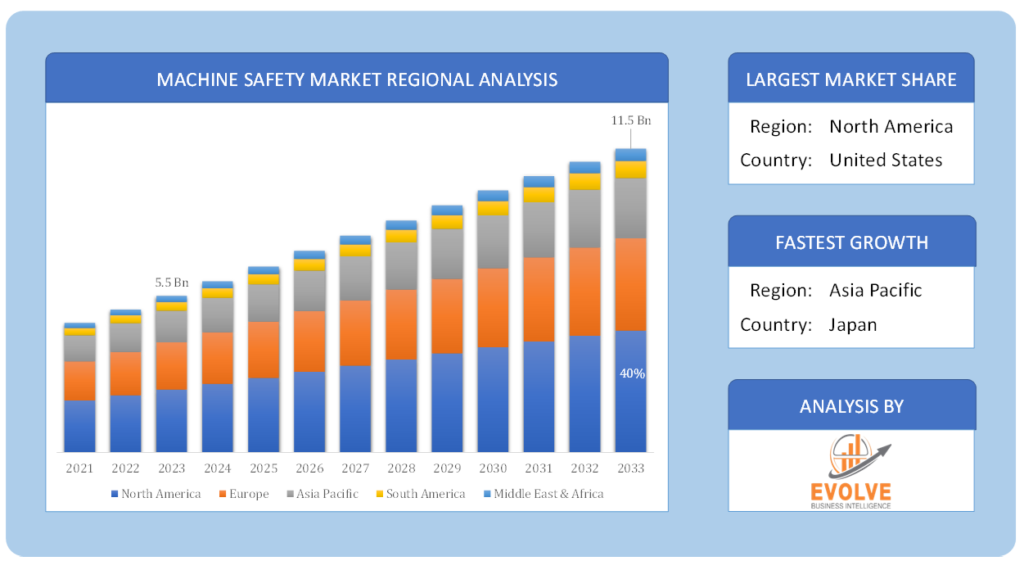

The global Machine Safety Market Size is expected to reach USD 11.5 Billion by 2033. The global Machine Safety industry size accounted for USD 5.5 billion in 2023 and is expected to expand at a compound annual growth rate (CAGR) of 6.9 % from 2023 to 2033. The machine safety market refers to the industry involved in ensuring the safety of machinery and equipment used across various sectors. Machine safety is of utmost importance to protect workers and prevent accidents in industrial settings. It involves the implementation of safety measures, technologies, and protocols to minimize the risks associated with operating machines.

Machine safety systems are widely used in industries such as manufacturing, oil and gas, automotive, healthcare, and mining, among others. These systems aim to prevent injuries, protect workers from hazardous conditions, and comply with regulatory standards. By implementing machine safety solutions, organizations can create a safe working environment, increase productivity, and reduce downtime due to accidents.

Global Machine Safety Market Synopsis

The COVID-19 pandemic had a significant impact on the machine safety market. During the initial phase of the pandemic, many industries experienced disruptions in their operations due to lockdowns and restrictions. This led to a decline in the demand for machine safety systems as industrial activities were put on hold.

However, the pandemic also highlighted the importance of worker safety and the need for robust safety measures in the workplace. As industries resumed operations post the COVID-19 lockdowns, there was an increased emphasis on implementing machine safety solutions to protect workers from potential risks and maintain a safe working environment.

Machine Safety Market Dynamics

The major factors that have impacted the growth of Machine Safety are as follows:

Drivers:

Ø Increasing Focus on Worker Safety

One of the key driving factors in the machine safety market is the increasing focus on worker safety. Employers are recognizing the importance of providing a safe working environment to their employees. The awareness of the potential risks associated with operating machinery and equipment has grown, leading to a greater demand for machine safety systems.

Safety regulations and standards imposed by regulatory bodies also play a significant role in driving the adoption of machine safety solutions. Companies are striving to comply with these regulations to avoid penalties and legal consequences. As a result, there is a growing need for advanced machine safety technologies and solutions that can effectively mitigate risks and ensure worker safety.

Restraint:

- Cost and Implementation Challenges

While the demand for machine safety systems is increasing, there are certain restraining factors that hinder market growth. One of the primary challenges is the cost associated with implementing machine safety measures. Upgrading existing machinery or installing new safety systems can be a significant investment for organizations, especially for small and medium-sized enterprises (SMEs). The cost factor often acts as a barrier, preventing some companies from fully embracing machine safety solutions.

Another restraining factor is the complexity of implementing machine safety systems. Integrating safety features into existing machinery requires expertise and careful planning. This process can be time-consuming and may disrupt production, leading to downtime. Organizations face challenges in retrofitting older machines with safety technologies or ensuring the compatibility of safety systems with different types of machinery.

Opportunity:

⮚ Technological Advancements and Automation

One of the significant opportunities in the machine safety market lies in technological advancements and automation. With the advent of Industry 4.0 and the Industrial Internet of Things (IIoT), machine safety is evolving to become more intelligent and interconnected. Advanced technologies such as machine learning, artificial intelligence, and real-time monitoring systems are being integrated into machine safety solutions.

These technological advancements enable predictive maintenance, remote monitoring, and enhanced safety protocols. Machine safety systems equipped with smart sensors and interconnected devices can provide real-time data on equipment performance, identify potential safety hazards, and initiate preventive measures. This opportunity allows organizations to optimize their machine safety strategies, improve productivity, and reduce accidents.

Machine Safety Segment Overview

By Component

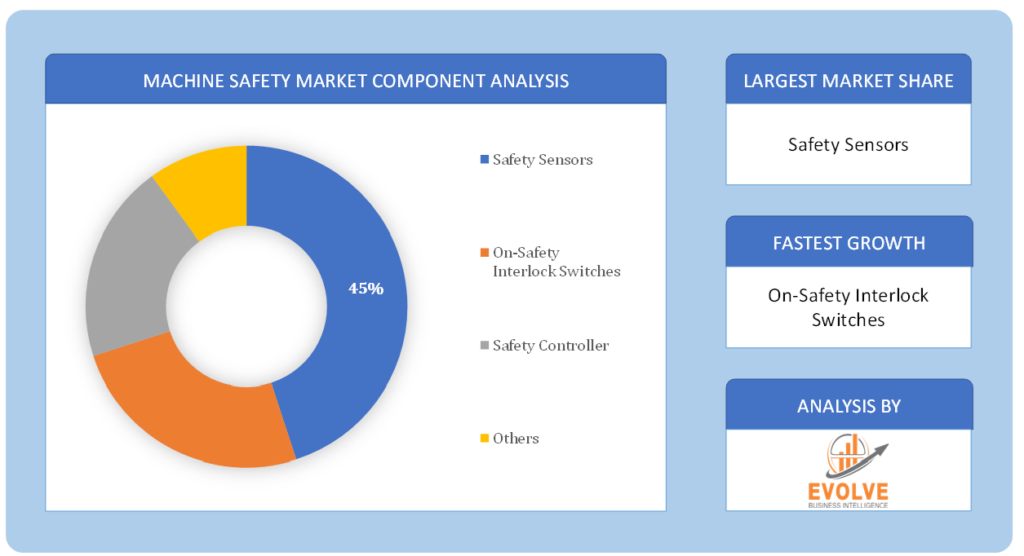

Based on the Component, the market is segmented based on Safety Sensors, and On-Safety Interlock Switches, Safety Controller, and Others. the Safety Sensors Component segment holds the largest share of the Machine Safety market. Safety sensors play a crucial role in detecting potential hazards and triggering safety mechanisms. On-safety interlock switches ensure that machines are properly shut down during maintenance or repair. Safety controllers provide the intelligence and control necessary for machine safety systems to function effectively.

Based on the Component, the market is segmented based on Safety Sensors, and On-Safety Interlock Switches, Safety Controller, and Others. the Safety Sensors Component segment holds the largest share of the Machine Safety market. Safety sensors play a crucial role in detecting potential hazards and triggering safety mechanisms. On-safety interlock switches ensure that machines are properly shut down during maintenance or repair. Safety controllers provide the intelligence and control necessary for machine safety systems to function effectively.

By Implementation

Based on Implementation, the market has been divided into Individual, and Embedded. The Individual segment holds the largest share of the market in terms of end-users. Individual solutions are standalone safety systems that can be retrofitted onto existing machinery. Embedded solutions, on the other hand, are integrated directly into the design of new machines or equipment. Embedded systems offer seamless integration and enhanced safety features, while individual solutions provide flexibility for retrofitting purposes.

Based on Industry Vertical, the market has been divided into Oil and Gas, Healthcare, Automotive, Metals and Mining, and Other Industry Verticals. the automotive industry is characterized by high production volumes and complex manufacturing processes. As a result, ensuring the safety of workers operating in such environments is of paramount importance. Machine safety systems play a crucial role in mitigating risks and preventing accidents in automotive assembly lines and manufacturing facilities. These systems are implemented to safeguard workers from hazards posed by heavy machinery, robotic systems, and automated equipment.

Global Machine Safety Market Regional Analysis

Based on region, the global Logistics Intelligence Software market has been divided into North America, Europe, Asia-Pacific, South America and Middle East & Africa. North America is projected to dominate the use of the market followed by the Europe and Asia-Pacific regions.

Machine Safety North America Market

Machine Safety North America Market

North America is a prominent region in the machine safety market. The region is characterized by stringent safety regulations, high industrial automation, and a strong focus on worker safety. Countries like the United States and Canada have well-established safety standards and regulatory frameworks that drive the demand for machine safety systems. The presence of key industry players, technological advancements, and a high emphasis on workplace safety contribute to the growth of the machine safety market in North America. The automotive, manufacturing, and oil and gas sectors are major contributors to the demand for machine safety solutions in the region.

Machine Safety Europe Market

Europe is another major region in the machine safety market. The region boasts a robust industrial base and a strong focus on worker safety. European countries such as Germany, France, and the United Kingdom have well-developed manufacturing sectors, including automotive, machinery, and chemicals, which drive the adoption of machine safety systems. The European Union (EU) has established comprehensive safety regulations and directives to ensure worker protection and product compliance. The presence of stringent safety standards, along with a growing emphasis on automation and Industry 4.0 initiatives, fuels the demand for machine safety solutions in Europe.

Competitive Landscape

The global logistics intelligence software market is highly competitive, with numerous players offering a wide range of software solutions. The competitive landscape is characterized by the presence of established companies, as well as emerging startups and niche players. To increase their market position and attract a wide consumer base, the businesses are employing various strategies, such as product launches, and strategic alliances.

Prominent Players:

- Rockwell Automation

- Schneider Electric SE

- Mitsubishi Electric Corporation

- Omron Corporation

- Pilz GmbH & Co. KG

- ABB Limited

- Honeywell International Inc.

- Siemens AG

- Keyence Corporation

- IDEC Corporation.

Key Development:

June 2022: Rockwell Automation, a leading player in the machine safety market, made a significant development. The company announced the launch of its new safety controller, the GuardLogix 5580, aimed at enhancing machine safety in industrial settings. The GuardLogix 5580 is designed to provide advanced safety functions, improved performance, and increased flexibility. With this development, Rockwell Automation aims to address the growing demand for robust and innovative machine safety solutions in the industry.

Scope of the Report

Global Machine Safety Market, by Component

- Safety Sensors

- On-Safety Interlock Switches

- Safety Controller

- Others

Global Machine Safety Market, by Implementation

- Individual

- Embedded

Global Machine Safety Market, by Industry Vertical

- Oil and Gas

- Healthcare

- Automotive

- Metals and Mining

- Other Industry Verticals

Global Machine Safety Market, by Region

- North America

- US

- Canada

- Mexico

- Europe

- UK

- Germany

- France

- Italy

- Spain

- Benelux

- Nordic

- Rest of Europe

- Asia Pacific

- China

- Japan

- South Korea

- Indonesia

- Austalia

- Malaysia

- India

- Rest of Asia Pacific

- South America

- Brazil

- Argentina

- Rest of South America

- Middle East & Africa

- Saudi Arabia

- UAE

- Egypt

- South Africa

- Rest of Middle East & Africa

| Parameters | Indicators |

|---|---|

| Market Size | 2033: $11.5 Billion |

| CAGR | 6.9% CAGR (2023-2033) |

| Base year | 2022 |

| Forecast Period | 2023-2033 |

| Historical Data | 2021 |

| Report Coverage | Revenue Forecast, Competitive Landscape, Growth Factors, and Trends |

| Key Segmentations | Component, Implementation, Industry Vertical |

| Geographies Covered | North America, Europe, Asia-Pacific, Latin America, Middle East, Africa |

| Key Vendors | Rockwell Automation, Schneider Electric SE, Mitsubishi Electric Corporation, Omron Corporation, Pilz GmbH & Co. KG, ABB Limited, Honeywell International Inc., Siemens AG, Keyence Corporation, and IDEC Corporation |

| Key Market Opportunities | Technological Advancements and Automation |

| Key Market Drivers | Increasing Focus on Worker Safety |

REPORT CONTENT BRIEF:

- High-level analysis of the current and future Machine Safety market trends and opportunities

- Detailed analysis of current market drivers, restraining factors, and opportunities in the future

- Machine Safety market historical market size for the year 2021, and forecast from 2023 to 2033

- Machine Safety market share analysis at each product level

- Competitor analysis with a detailed insight into its product segment, Embedded strength, and strategies adopted.

- Identifies key strategies adopted including product launches and developments, mergers and acquisitions, joint ventures, collaborations, and partnerships as well as funding taken and investment done, among others.

- To identify and understand the various factors involved in the global Machine Safety market affected by the pandemic

- To provide a detailed insight into the major companies operating in the market. The profiling will include the Embedded health of the company’s past 2-3 years with segmental and regional revenue breakup, product offering, recent developments, SWOT analysis, and key strategies.

Press Release

Global Pharmaceutical Manufacturing Market to Reach $1.38 Trillion by 2035 with 7.35% CAGR, New Research Shows

The Global Mammography Market Is Estimated To Record a CAGR of Around 10.29% During The Forecast Period

Glue Stick Market to Reach USD 2.35 Billion by 2034

Podiatry Service Market to Reach USD 11.88 Billion by 2034

Microfluidics Technology Market to Reach USD 32.58 Billion by 2034

Ferric Chloride Market to Reach USD 10.65 Billion by 2034

Family Practice EMR Software Market to Reach USD 21.52 Billion by 2034

Electric Hairbrush Market to Reach USD 15.95 Billion by 2034

Daily Bamboo Products Market to Reach USD 143.52 Billion by 2034

Cross-border E-commerce Logistics Market to Reach USD 112.65 Billion by 2034

Frequently Asked Questions (FAQ)

The study period of the global Machine Safety market is 2021- 2033

The global Machine Safety market is growing at a CAGR of 6.9% over the next 10 years

North America is expected to register the highest CAGR during 2023-2033

Europe holds the largest share in 2022

Rockwell Automation, Schneider Electric SE, Mitsubishi Electric Corporation, Omron Corporation, Pilz GmbH & Co. KG, ABB Limited, Honeywell International Inc., Siemens AG, Keyence Corporation, and IDEC Corporation. are the major companies operating in the market.

Yes, we offer 16 hours of analyst support to solve the queries

Yes, we provide regional as well as country-level reports. Other than this we also provide a sectional report. Please get in contact with our sales representatives.

Table of Content

Chapter 1. Executive Summary Chapter 2. Scope Of The Study 2.1. Market Definition 2.2. Scope Of The Study 2.2.1. Objectives of Report 2.2.2. Limitations 2.3. Market Structure Chapter 3. Evolve BI Methodology Chapter 4. Market Insights and Trends 4.1. Supply/ Value Chain Analysis 4.1.1. Raw Implementation Providers 4.1.2. Manufacturing Process 4.1.3. Distributors/Healthcareers 4.1.4. End-Use Industry 4.2. Porter’s Five Forces Analysis 4.2.1. Threat Of New Entrants 4.2.2. Bargaining Power Of Buyers 4.2.3. Bargaining Power Of Suppliers 4.2.4. Threat Of Substitutes 4.2.5. Industry Rivalry 4.3. Impact Of COVID-19 on the Machine Safety Market 4.3.1. Impact on Market Size 4.3.2. End-Use Industry Trend, Preferences, and Budget Impact 4.3.3. Regulatory Framework/Government Policies 4.3.4. Key Players' Strategy to Tackle Negative Impact 4.3.5. Opportunity Window 4.4. Technology Overview 4.5. Macro factor 4.6. Micro Factor 4.7. Demand Supply Gap Analysis of the Machine Safety Market 4.8. Import Analysis of the Machine Safety Market 4.9. Export Analysis of the Machine Safety Market Chapter 5. Market Dynamics 5.1. Introduction 5.2. DROC Analysis 5.2.1. Drivers 5.2.2. Restraints 5.2.3. Opportunities 5.2.4. Challenges 5.3. Patent Analysis 5.4. Industry Roadmap 5.5. Parent/Peer Market Analysis Chapter 6. Global Machine Safety Market, By Component 6.1. Introduction 6.2. Safety Sensors 6.3. On-Safety Interlock Switches Chapter 7. Global Machine Safety Market, By Implementation 7.1. Introduction 7.2. Individual 7.3. Embedded Chapter 8. Global Machine Safety Market, By Industry Vertical 8.1. Introduction 8.2. Oil and Gas 8.3. Healthcare Chapter 9. Global Machine Safety Market, By Region 9.1. Introduction 9.2. North America 9.2.1. Introduction 9.2.2. Driving Factors, Opportunity Analyzed, and Key Trends 9.2.3. Market Size and Forecast, By Country, 2023-2033 9.2.4. Market Size and Forecast, By Component, 2023-2033 9.2.5. Market Size and Forecast, By Implementation, 2023-2033 9.2.6. Market Size and Forecast, By Industry Vertical, 2023-2033 9.2.7. US 9.2.7.1. Introduction 9.2.7.2. Driving Factors, Opportunity Analyzed, and Key Trends 8.2.7.3. Market Size and Forecast, By Component, 2023-2033 8.2.7.4. Market Size and Forecast, By Implementation, 2023-2033 8.2.7.5. Market Size and Forecast, By Industry Vertical, 2023-2033 9.2.8. Canada 9.2.8.1. Introduction 9.2.8.2. Driving Factors, Opportunity Analyzed, and Key Trends 9.2.8.4. Market Size and Forecast, By Component, 2023-2033 9.2.8.5. Market Size and Forecast, By Implementation, 2023-2033 9.2.8.6. Market Size and Forecast, By Industry Vertical, 2023-2033 9.3. Europe 9.3.1. Introduction 9.3.2. Driving Factors, Opportunity Analyzed, and Key Trends 9.3.3. Market Size and Forecast, By Country, 2023-2033 9.3.4. Market Size and Forecast, By Component, 2023-2033 9.3.5. Market Size and Forecast, By Implementation, 2023-2033 9.3.6. Market Size and Forecast, By Industry Vertical, 2023-2033 9.3.7. Germany 9.3.7.1. Introduction 9.3.7.2. Driving Factors, Opportunity Analyzed, and Key Trends 9.3.7.3. Market Size and Forecast, By Component, 2023-2033 9.3.7.4. Market Size and Forecast, By Implementation, 2023-2033 9.3.7.5. Market Size and Forecast, By Industry Vertical, 2023-2033 9.3.8. France 9.3.8.1. Introduction 9.3.8.2. Driving Factors, Opportunity Analyzed, and Key Trends 9.3.8.3. Market Size and Forecast, By Component, 2023-2033 9.3.8.4. Market Size and Forecast, By Implementation, 2023-2033 9.3.8.5. Market Size and Forecast, By Industry Vertical, 2023-2033 9.3.9. UK 9.3.9.1. Introduction 9.3.9.2. Driving Factors, Opportunity Analyzed, and Key Trends 9.3.9.3. Market Size and Forecast, By Component, 2023-2033 9.3.9.4. Market Size and Forecast, By Implementation, 2023-2033 9.3.9.5. Market Size and Forecast, By Industry Vertical, 2023-2033 9.3.10. Italy 9.3.10.1. Introduction 9.3.10.2. Driving Factors, Opportunity Analyzed, and Key Trends 9.3.10.3. Market Size and Forecast, By Component, 2023-2033 9.3.10.4. Market Size and Forecast, By Implementation, 2023-2033 9.3.10.5. Market Size and Forecast, By Industry Vertical, 2023-2033 9.4.11. Rest Of Europe 9.4.11.1. Introduction 9.4.11.2. Driving Factors, Opportunity Analyzed, and Key Trends 9.4.11.3. Market Size and Forecast, By Component, 2023-2033 9.4.11.4. Market Size and Forecast, By Industry Vertical, 2023-2033 9.5. Asia-Pacific 9.5.1. Introduction 9.5.2. Driving Factors, Opportunity Analyzed, and Key Trends 9.5.3. Market Size and Forecast, By Country, 2023-2033 9.5.4. Market Size and Forecast, By Component, 2023-2033 9.5.5. Market Size and Forecast, By Implementation, 2023-2033 9.5.6. Market Size and Forecast, By Industry Vertical, 2023-2033 9.5.7. China 9.5.7.1. Introduction 9.5.7.2. Driving Factors, Opportunity Analyzed, and Key Trends 9.5.7.3. Market Size and Forecast, By Component, 2023-2033 9.5.7.4. Market Size and Forecast, By Implementation, 2023-2033 9.5.7.5. Market Size and Forecast, By Industry Vertical, 2023-2033 9.5.8. India 9.5.8.1. Introduction 9.5.8.2. Driving Factors, Opportunity Analyzed, and Key Trends 9.5.8.3. Market Size and Forecast, By Component, 2023-2033 9.5.8.4. Market Size and Forecast, By Implementation, 2023-2033 9.5.8.5. Market Size and Forecast, By Industry Vertical, 2023-2033 9.5.9. Japan 9.5.9.1. Introduction 9.5.9.2. Driving Factors, Opportunity Analyzed, and Key Trends 9.5.9.3. Market Size and Forecast, By Component, 2023-2033 9.5.9.4. Market Size and Forecast, By Implementation, 2023-2033 9.5.9.5. Market Size and Forecast, By Industry Vertical, 2023-2033 9.5.10. South Korea 9.5.10.1. Introduction 9.5.10.2. Driving Factors, Opportunity Analyzed, and Key Trends 9.5.10.3. Market Size and Forecast, By Component, 2023-2033 9.5.10.4. Market Size and Forecast, By Implementation, 2023-2033 9.5.10.5. Market Size and Forecast, By Industry Vertical, 2023-2033 9.5.11. Rest Of Asia-Pacific 9.5.11.1. Introduction 9.5.11.2. Driving Factors, Opportunity Analyzed, and Key Trends 9.5.11.3. Market Size and Forecast, By Component, 2023-2033 9.5.11.4. Market Size and Forecast, By Implementation, 2023-2033 9.5.11.5. Market Size and Forecast, By Industry Vertical, 2023-2033 9.6. Rest Of The World (RoW) 9.6.1. Introduction 9.6.2. Driving Factors, Opportunity Analyzed, and Key Trends 9.6.3. Market Size and Forecast, By Component, 2023-2033 9.6.4. Market Size and Forecast, By Implementation, 2023-2033 9.6.5. Market Size and Forecast, By Industry Vertical, 2023-2033 Chapter 9. Company Landscape 9.1. Introduction 9.2. Vendor Share Analysis 9.3. Key Development Analysis 9.4. Competitor Dashboard Chapter 10. Company Profiles 10.1. Rockwell Automation 10.1.1. Business Overview 10.1.2. Embedded Analysis 10.1.3. Product Portfolio 10.1.4. Recent Development and Strategies Adopted 10.1.5. SWOT Analysis 10.2. Schneider Electric SE 10.2.1. Business Overview 10.2.2. Embedded Analysis 10.2.3. Product Portfolio 10.2.4. Recent Development and Strategies Adopted 10.2.5. SWOT Analysis 10.3. Mitsubishi Electric Corporation 10.3.1. Business Overview 10.3.2. Embedded Analysis 10.3.3. Product Portfolio 10.3.4. Recent Development and Strategies Adopted 10.3.5. SWOT Analysis 10.4. Omron Corporation. 10.4.1. Business Overview 10.4.2. Embedded Analysis 10.4.3. Product Portfolio 10.4.4. Recent Development and Strategies Adopted 10.4.5. SWOT Analysis 10.5. Pilz GmbH & Co. KG 10.5.1. Business Overview 10.5.2. Embedded Analysis 10.5.3. Product Portfolio 10.5.4. Recent Development and Strategies Adopted 10.5.5. SWOT Analysis 10.6. ABB Limited 10.6.1. Business Overview 10.6.2. Embedded Analysis 10.6.3. Product Portfolio 10.6.4. Recent Development and Strategies Adopted 10.6.5. SWOT Analysis 10.7. Honeywell International Inc. 10.7.1. Business Overview 10.7.2. Embedded Analysis 10.7.3. Product Portfolio 10.7.4. Recent Development and Strategies Adopted 10.7.5. SWOT Analysis 10.8 Siemens AG 10.8.1. Business Overview 10.8.2. Embedded Analysis 10.8.3. Product Portfolio 10.8.4. Recent Development and Strategies Adopted 10.8.5. SWOT Analysis 10.9. Keyence Corporation 10.9.1. Business Overview 10.9.2. Embedded Analysis 10.9.3. Product Portfolio 10.9.4. Recent Development and Strategies Adopted 10.9.5. SWOT Analysis 10.10. IDEC Corporation 10.10.1. Business Overview 10.10.2. Embedded Analysis 10.10.3. Product Portfolio 10.10.4. Recent Development and Strategies Adopted 10.10.5. SWOT Analysis

Connect to Analyst

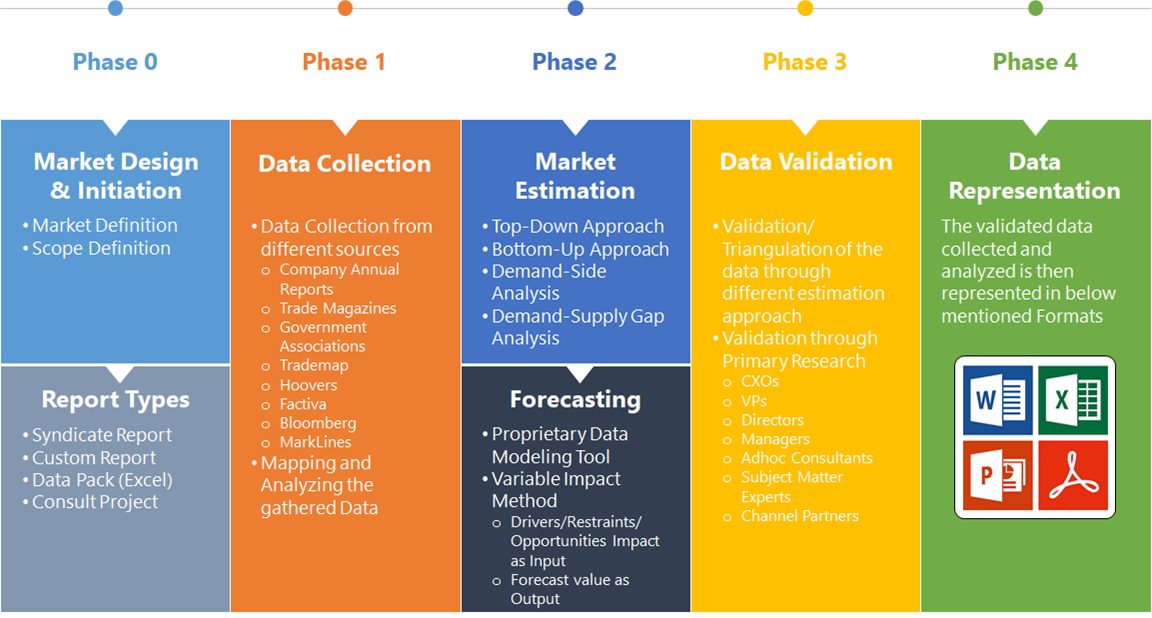

Research Methodology