Machine Condition Monitoring Market Analysis and Global Forecast 2021-2034

$ 1,390.00 – $ 5,520.00Price range: $ 1,390.00 through $ 5,520.00

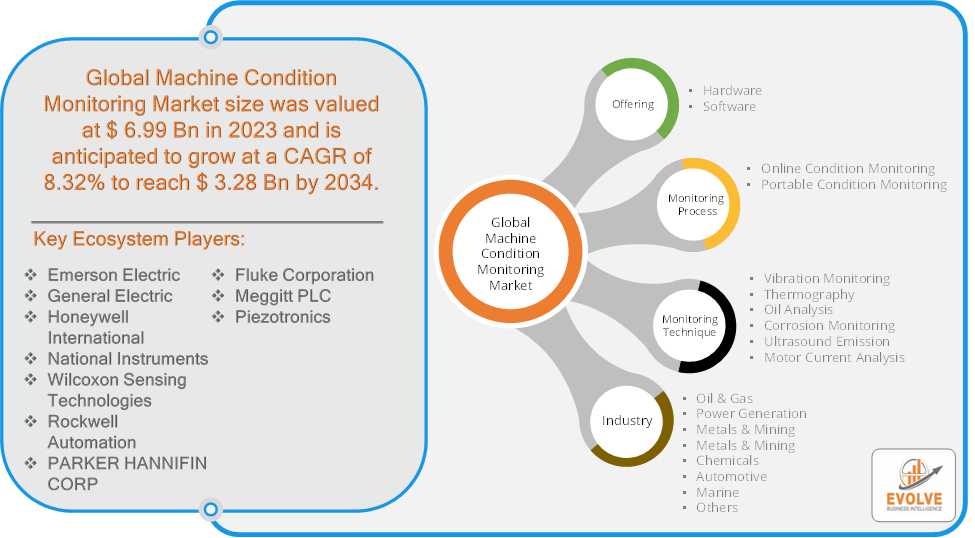

Machine Condition Monitoring Market Research Report: By Offering (Hardware, Software), By Monitoring Process (Online Condition Monitoring, Portable Condition Monitoring), By Monitoring Technique (Vibration Monitoring, Thermography, Oil Analysis, Corrosion Monitoring, Ultrasound Emission, Motor Current Analysis), By Industry (Oil & Gas, Power Generation, Metals & Mining, Chemicals, Automotive, Marine, Others), and by Region — Forecast till 2034

Page: 168

Machine Condition Monitoring Market Overview

The Machine Condition Monitoring Market size accounted for USD 3.28 Billion in 2023 and is estimated to account for 4.79 Billion in 2024. The Market is expected to reach USD 6.99 Billion by 2034 growing at a compound annual growth rate (CAGR) of 8.32% from 2024 to 2034. The technologies and methods used to evaluate the performance and condition of machinery across a range of industries are the main focus of the machine condition monitoring market. This market includes a variety of solutions, such as oil analysis, vibration analysis, thermal imaging, and acoustic emission monitoring. By assisting in the early detection of possible problems before they result in equipment failure, these instruments enable predictive maintenance plans that can lower maintenance costs and downtime. The market is driven by the manufacturing and industrial sectors’ growing need for operational efficiency, sustainability, and safety. Manufacturing facilities, power plants, and the transportation industry are important end customers. The incorporation of smart sensors and data analytics further boosts monitoring capabilities as industries embrace the Internet of Things (IoT), hence driving market expan

Global Machine Condition Monitoring Market Synopsis

Global Machine Condition Monitoring Market Dynamics

Global Machine Condition Monitoring Market Dynamics

The major factors that have impacted the growth of Machine Condition Monitoring are as follows:

Drivers:

⮚ Advancements in IoT and Industry 4.0

Industry 4.0 and the Internet of Things (IoT) have completely changed how industries manufacture goods and operate. The accuracy of condition assessments is improved by real-time monitoring and data collection made possible by smart sensors and connected devices. More advanced analytics and machine learning applications that can more reliably predict problems are made possible by this combination.

Restraint:

- Concerns About Data Security

Data security and privacy issues have surfaced as condition monitoring systems grow more networked and dependent on cloud-based services. Businesses may be reluctant to use these technologies due to concerns about the possibility of data breaches, especially in delicate sectors like healthcare and finance.

Opportunity:

⮚ Expansion of Industrial Internet of Things (IIoT)

Machine condition monitoring has a lot of potential thanks to the quick development and widespread use of IIoT technology. The capabilities of condition monitoring systems are improved by IIoT, which makes real-time data collection and processing easier. Monitoring solutions can offer deeper insights into equipment performance by combining with smart sensors and linked devices, allowing for more proactive maintenance strategies.

Machine Condition Monitoring Market Segment Overview

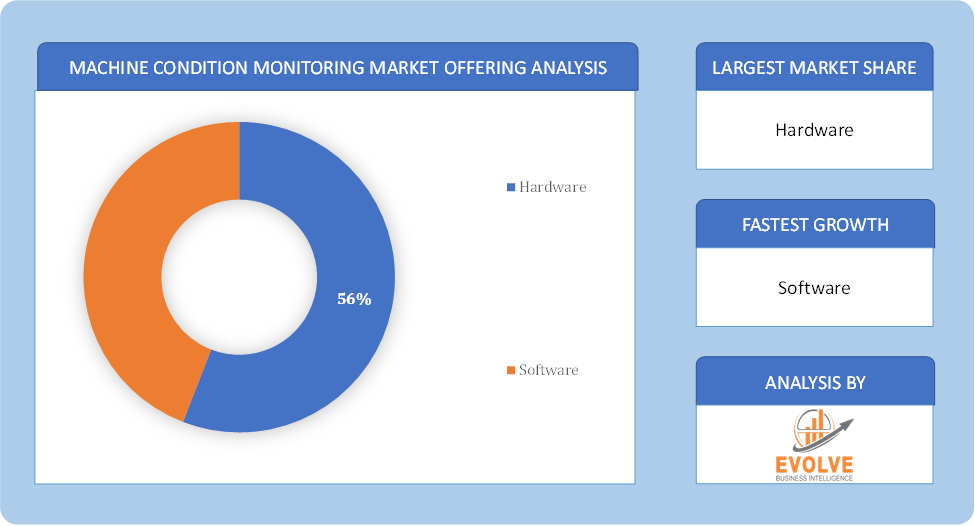

Based on the Offering, the market is segmented based on Hardware, Software. Hardware dominates the segment, as it includes essential components like sensors and monitoring devices that are critical for collecting data on machine performance and condition.

By Monitoring Process

Based on Monitoring Process, the market has been divided into Online Condition Monitoring, Portable Condition Monitoring. Online Condition Monitoring is the dominant segment, as it allows for real-time, continuous data collection and analysis, enabling proactive maintenance and immediate response to equipment issues.

By Monitoring Technique

Based on the Monitoring Technique, the market has been divided into Vibration Monitoring, Thermography, Oil Analysis, Corrosion Monitoring, Ultrasound Emission, Motor Current Analysis. Vibration Monitoring is the dominant segment, as it is widely used for its effectiveness in detecting early signs of equipment failure and its applicability across various industries.

By Industry

Based on Industry , the market has been divided into Oil & Gas, Power Generation, Metals & Mining, Chemicals, Automotive, Marine, Others. the Oil & Gas industry typically dominates due to its critical reliance on equipment performance and safety, necessitating continuous monitoring to prevent costly downtimes and accidents.

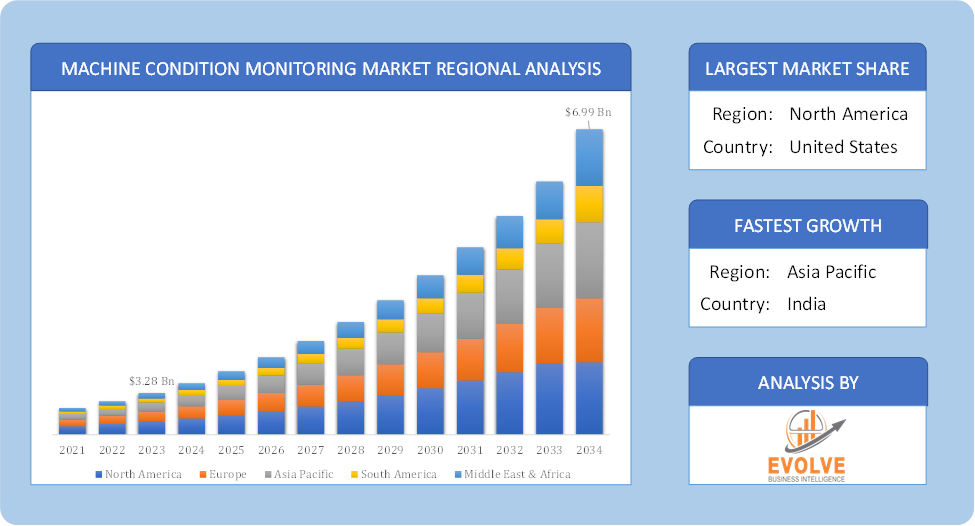

Global Machine Condition Monitoring Market Regional Analysis

Based on region, the market has been divided into North America, Europe, Asia-Pacific, the Middle East & Africa, and Latin America. The area of North America is anticipated to dominate the market for the usage of Machine Condition Monitoring, followed by those in Asia-Pacific and Europe.

Machine Condition Monitoring North America Market

Machine Condition Monitoring North America Market

The North American region holds a dominant position in the Machine Condition Monitoring market. This market will be dominated by the machine condition monitoring sector in North America. It is anticipated that the United States and Canada will have substantial growth opportunity in comparison to the robust demand from the power generation, aerospace, oil & gas, marine, and food & beverage industries. Vibration monitoring has been a popular technique for oil condition monitoring in the equipment lubricants used on oil and gas platforms.

Machine Condition Monitoring Asia Pacific Market

The Asia-Pacific region is witnessing rapid growth and emerging as a significant market for the Machine Condition Monitoring industry. The market for machine condition monitoring in Asia-Pacific is anticipated to expand at the quickest rate between 2023 and 2032 (CAGR of ). This segment’s substantial market share can be attributed to several factors, including the substantial increase in industrial robot deployment, the growing need for automation, and the presence of high-production countries like China and Japan. Furthermore, in the Asia-Pacific region, the machine condition monitoring market in Japan was increasing at the fastest rate, while the market in China held the greatest market share.

Competitive Landscape

The competitive landscape includes key players (tier 1, tier 2, and local) having a presence across the globe. Companies such as Emerson Electric, General Electric, Honeywell International, National Instruments, and Wilcoxon Sensing Technologies are some of the leading players in the global Machine Condition Monitoring Industry. These players have adopted partnership, acquisition, expansion, and new product development, among others as their key strategies.

Key Market Players:

- Emerson Electric

- General Electric

- Honeywell International

- National Instruments

- Wilcoxon Sensing Technologies

- Rockwell Automation

- PARKER HANNIFIN CORP

- Fluke Corporation

- Meggitt PLC

- Piezotronics

Key Development:

In September 2023, Honeywell International announced enhancements to its condition monitoring solutions, incorporating advanced analytics and machine learning capabilities to improve predictive maintenance and operational efficiency across various industries.

Scope of the Report

Global Machine Condition Monitoring Market, by Offering

- Hardware

- Software

Global Machine Condition Monitoring Market, by Monitoring Process

- Online Condition Monitoring

- Portable Condition Monitoring

Global Machine Condition Monitoring Market, by Monitoring Technique

- Vibration Monitoring

- Thermography

- Oil Analysis

- Corrosion Monitoring

- Ultrasound Emission

- Motor Current Analysis

Global Machine Condition Monitoring Market, by Industry

- Oil & Gas

- Power Generation

- Metals & Mining

- Metals & Mining

- Chemicals

- Automotive

- Marine

- Others

Global Machine Condition Monitoring Market, by Region

- North America

- US

- Canada

- Mexico

- Europe

- UK

- Germany

- France

- Italy

- Spain

- Benelux

- Nordic

- Rest of Europe

- Asia Pacific

- China

- Japan

- South Korea

- Indonesia

- Austalia

- Malaysia

- India

- Rest of Asia Pacific

- South America

- Brazil

- Argentina

- Rest of South America

- Middle East & Africa

- Saudi Arabia

- UAE

- Egypt

- South Africa

- Rest of Middle East & Africa

| Parameters | Indicators |

|---|---|

| Market Size | 2034: USD 6.99 Billion |

| CAGR (2021-2034) | 8.32% |

| Base year | 2023 |

| Forecast Period | 2021-2034 |

| Historical Data | 2021 (2017 to 2020 On Demand) |

| Report Coverage | Revenue Forecast, Competitive Landscape, Growth Factors, and Trends |

| Key Segmentations | Offering, Monitoring Process, Monitoring Technique , Industry |

| Geographies Covered | North America, Europe, Asia-Pacific, South America, Middle East, Africa. |

| Key Vendors | Emerson Electric, General Electric, Honeywell International, National Instruments, Wilcoxon Sensing Technologies, Rockwell Automation, PARKER HANNIFIN CORP, Fluke Corporation, Meggitt PLC, Piezotronics |

| Key Market Opportunities | Increase in adoption of industry 4.0 |

| Key Market Drivers | Rise in need for predictive maintenance and product innovations by market players |

REPORT CONTENT BRIEF:

- High-level analysis of the current and future Machine Condition Monitoring market trends and opportunities

- Detailed analysis of current market drivers, restraining factors, and opportunities in the future

- Machine Condition Monitoring market historical market size for the year 2022, and forecast from 2021 to 2034

- Machine Condition Monitoring market share analysis at each product level

- Competitor analysis with detailed insight into its product segment, Government & Defense strength, and strategies adopted.

- Identifies key strategies adopted including product launches and developments, mergers and acquisitions, joint ventures, collaborations, and partnerships as well as funding taken and investment done, among others.

- To identify and understand the various factors involved in the global Machine Condition Monitoring market affected by the pandemic

- To provide a detailed insight into the major companies operating in the market. The profiling will include the Government & Defense health of the company’s past 2-3 years with segmental and regional revenue breakup, product offering, recent developments, SWOT analysis, and key strategies.

Frequently Asked Questions (FAQ)

What is the study period of this market?

The study period of the global Machine Condition Monitoring market is 2021- 2034

What are the 10 Years CAGR (2021 to 2034) of the global Machine Condition Monitoring market?

The global Machine Condition Monitoring market is growing at a CAGR of ~8.32% over the next 10 years

Which region has the highest growth rate in the market of Machine Condition Monitoring?

Asia Pacific is expected to register the highest CAGR during 2021-2034

Which region accounted for the largest share of the market of Machine Condition Monitoring?

North America holds the largest share in 2023

Major Key Players in the Market of Machine Condition Monitoring?

Emerson Electric, General Electric, Honeywell International, National Instruments, Wilcoxon Sensing Technologies, Rockwell Automation, PARKER HANNIFIN CORP, Fluke Corporation, Meggitt PLC, and Piezotronics are the major companies operating in the Machine Condition Monitoring Industry.

Do you offer Post Sale Support?

Yes, we offer 16 hours of analyst support to solve the queries

Do you deliver sections of a report?

Yes, we do provide regional as well as country-level reports. Other than this we also provide a sectional report. Please get in contact with our sales representatives.

Press Release

Global Pharmaceutical Manufacturing Market to Reach $1.38 Trillion by 2035 with 7.35% CAGR, New Research Shows

The Global Mammography Market Is Estimated To Record a CAGR of Around 10.29% During The Forecast Period

Glue Stick Market to Reach USD 2.35 Billion by 2034

Podiatry Service Market to Reach USD 11.88 Billion by 2034

Microfluidics Technology Market to Reach USD 32.58 Billion by 2034

Ferric Chloride Market to Reach USD 10.65 Billion by 2034

Family Practice EMR Software Market to Reach USD 21.52 Billion by 2034

Electric Hairbrush Market to Reach USD 15.95 Billion by 2034

Daily Bamboo Products Market to Reach USD 143.52 Billion by 2034

Cross-border E-commerce Logistics Market to Reach USD 112.65 Billion by 2034

Table of Content

CHAPTER 1. Executive Summary CHAPTER 2. Scope of the Study 2.1. Market Definition 2.2. Market Scope & Segmentation 2.2.1. Objective of Report CHAPTER 3. Evolve BI Methodology 3.1. Data Collection & Validation Approach 3.2. Market Size Estimation and Forecast CHAPTER 4. Exclusive Analysis 4.1. Market Opportunity Score 4.1.1. Offering Segement – Market Opportunity Score 4.1.2. Monitoring Process Segment – Market Opportunity Score 4.1.3. Monitoring Technique Segment – Market Opportunity Score 4.1.4. Industry Segment – Market Opportunity Score 4.2. Key Market Influencing Indicators CHAPTER 5. Market Insights and Trends 5.1. Value Chain Analysis 5.1.1. Offering 5.1.2. Manufacturing Process 5.1.3. Distribution Channel 5.1.4. End User 5.2. Porter’s Five Forces Analysis 5.2.1. Bargaining Power of Buyers 5.2.2. Bargaining Power of Suppliers 5.2.3. Threat of New Entrant 5.2.4. Threat of Substitute 5.2.5. Industry Rivalry 5.3. COVID-19 Impact and Post COVID Scenario on Machine Condition Monitoring Market 5.3.1. Impact of COVID-19 5.3.2. Government Support and Industry Revival Policies 5.3.3. Measures Taken by Companies to Mitigate Negative Impact 5.3.4. Post COVID Trend CHAPTER 6. MArket Dynamics 6.1. Introduction 6.2. Drivers 6.2.1. Driver 1 6.2.2. Driver 2 6.2.3. Driver 3 6.3. Restraints 6.3.1. Restraint 1 6.3.2. Restraint 2 6.4. Opportunity 6.4.1. Opportunity 1 CHAPTER 7. Global Machine Condition Monitoring Market, By Offering 7.1. Introduction 7.1.1. Hardware 7.1.2. Software CHAPTER 8. Global Machine Condition Monitoring Market, By Monitoring Process 8.1. Introduction 8.1.1. Online Condition Monitoring 8.1.2. Portable Condition Monitoring CHAPTER 9. Global Machine Condition Monitoring Market, By Monitoring Technique 9.1. Introduction 9.1.1. Vibration Monitoring 9.1.2. Thermography 9.1.3. Oil Analysis 9.1.4. Corrosion Monitoring 9.1.5. Ultrasound Emission 9.1.6. Motor Current Analysis CHAPTER 10. Global Machine Condition Monitoring Market, By Industry 10.1. Introduction 10.1.1. Oil & Gas 10.1.2. Power Generation 10.1.3. Metals & Mining 10.1.4. Metals & Mining 10.1.5. Chemicals 10.1.6. Automotive 10.1.7. Marine 10.1.8. Others CHAPTER 11. Global Machine Condition Monitoring Market, By Region 11.1. Introduction 11.2. NORTH AMERICA 11.2.1. North America: Market Size and Forecast, By Country, 2021 – 2034 ($ Million) 11.2.2. North America: Market Size and Forecast, By Offering, 2021 – 2034 ($ Million) 11.2.3. North America: Market Size and Forecast, By Monitoring Process, 2021 – 2034 ($ Million) 11.2.4. North America: Market Size and Forecast, By Monitoring Technique , 2021 – 2034 ($ Million) 11.2.5. North America: Market Size and Forecast, By Industry , 2021 – 2034 ($ Million) 11.2.6. US 11.2.6.1. US: Market Size and Forecast, By Offering, 2021 – 2034 ($ Million) 11.2.6.2. US: Market Size and Forecast, By Monitoring Process, 2021 – 2034 ($ Million) 11.2.6.3. US: Market Size and Forecast, By Monitoring Technique , 2021 – 2034 ($ Million) 11.2.6.4. US: Market Size and Forecast, By Industry , 2021 – 2034 ($ Million) 11.2.7. CANADA 11.2.7.1. Canada: Market Size and Forecast, By Offering, 2021 – 2034 ($ Million) 11.2.7.2. Canada: Market Size and Forecast, By Monitoring Process, 2021 – 2034 ($ Million) 11.2.7.3. Canada: Market Size and Forecast, By Monitoring Technique , 2021 – 2034 ($ Million) 11.2.7.4. Canada: Market Size and Forecast, By Industry , 2021 – 2034 ($ Million) 11.2.8. MEXICO 11.2.8.1. Mexico: Market Size and Forecast, By Offering, 2021 – 2034 ($ Million) 11.2.8.2. Mexico: Market Size and Forecast, By Monitoring Process, 2021 – 2034 ($ Million) 11.2.8.3. Mexico: Market Size and Forecast, By Monitoring Technique , 2021 – 2034 ($ Million) 11.2.8.4. Mexico: Market Size and Forecast, By Industry , 2021 – 2034 ($ Million) 11.3. Europe 11.3.1. Europe: Market Size and Forecast, By Country, 2021 – 2034 ($ Million) 11.3.2. Europe: Market Size and Forecast, By Offering, 2021 – 2034 ($ Million) 11.3.3. Europe: Market Size and Forecast, By Monitoring Process, 2021 – 2034 ($ Million) 11.3.4. Europe: Market Size and Forecast, By Monitoring Technique , 2021 – 2034 ($ Million) 11.3.5. Europe: Market Size and Forecast, By Industry , 2021 – 2034 ($ Million) 11.3.6. U.K. 11.3.6.1. U.K.: Market Size and Forecast, By Offering, 2021 – 2034 ($ Million) 11.3.6.2. U.K.: Market Size and Forecast, By Monitoring Process, 2021 – 2034 ($ Million) 11.3.6.3. U.K.: Market Size and Forecast, By Monitoring Technique , 2021 – 2034 ($ Million) 11.3.6.4. U.K.: Market Size and Forecast, By Industry , 2021 – 2034 ($ Million) 11.3.7. GERMANY 11.3.7.1. Germany: Market Size and Forecast, By Offering, 2021 – 2034 ($ Million) 11.3.7.2. Germany: Market Size and Forecast, By Monitoring Process, 2021 – 2034 ($ Million) 11.3.7.3. Germany: Market Size and Forecast, By Monitoring Technique , 2021 – 2034 ($ Million) 11.3.7.4. Germany: Market Size and Forecast, By Industry , 2021 – 2034 ($ Million) 11.3.8. FRANCE 11.3.8.1. France: Market Size and Forecast, By Offering, 2021 – 2034 ($ Million) 11.3.8.2. France: Market Size and Forecast, By Monitoring Process, 2021 – 2034 ($ Million) 11.3.8.3. France: Market Size and Forecast, By Monitoring Technique , 2021 – 2034 ($ Million) 11.3.8.4. France: Market Size and Forecast, By Industry , 2021 – 2034 ($ Million) 11.3.9. ITALY 11.3.9.1. Italy: Market Size and Forecast, By Offering, 2021 – 2034 ($ Million) 11.3.9.2. Italy: Market Size and Forecast, By Monitoring Process, 2021 – 2034 ($ Million) 11.3.9.3. Italy: Market Size and Forecast, By Monitoring Technique , 2021 – 2034 ($ Million) 11.3.9.4. Italy: Market Size and Forecast, By Industry , 2021 – 2034 ($ Million) 11.3.10. SPAIN 11.3.10.1. Spain: Market Size and Forecast, By Offering, 2021 – 2034 ($ Million) 11.3.10.2. Spain: Market Size and Forecast, By Monitoring Process, 2021 – 2034 ($ Million) 11.3.10.3. Spain: Market Size and Forecast, By Monitoring Technique , 2021 – 2034 ($ Million) 11.3.10.4. Spain: Market Size and Forecast, By Industry , 2021 – 2034 ($ Million) 11.3.11. BENELUX 11.3.11.1. BeNeLux: Market Size and Forecast, By Offering, 2021 – 2034 ($ Million) 11.3.11.2. BeNeLux: Market Size and Forecast, By Monitoring Process, 2021 – 2034 ($ Million) 11.3.11.3. BeNeLux: Market Size and Forecast, By Monitoring Technique , 2021 – 2034 ($ Million) 11.3.11.4. BeNeLux: Market Size and Forecast, By Industry , 2021 – 2034 ($ Million) 11.3.12. RUSSIA 11.3.12.1. Russia: Market Size and Forecast, By Offering, 2021 – 2034 ($ Million) 11.3.12.2. Russia: Market Size and Forecast, By Monitoring Process, 2021 – 2034 ($ Million) 11.3.12.3. Russia: Market Size and Forecast, By Monitoring Technique , 2021 – 2034 ($ Million) 11.3.12.4. Russia: Market Size and Forecast, By Industry , 2021 – 2034 ($ Million) 11.3.13. REST OF EUROPE 11.3.13.1. Rest of Europe: Market Size and Forecast, By Offering, 2021 – 2034 ($ Million) 11.3.13.2. Rest of Europe: Market Size and Forecast, By Monitoring Process, 2021 – 2034 ($ Million) 11.3.13.3. Rest of Europe: Market Size and Forecast, By Monitoring Technique , 2021 – 2034 ($ Million) 11.3.13.4. Rest of Europe: Market Size and Forecast, By Industry , 2021 – 2034 ($ Million) 11.4. Asia Pacific 11.4.1. Asia Pacific: Market Size and Forecast, By Country, 2021 – 2034 ($ Million) 11.4.2. Asia Pacific: Market Size and Forecast, By Offering, 2021 – 2034 ($ Million) 11.4.3. Asia Pacific: Market Size and Forecast, By Monitoring Process, 2021 – 2034 ($ Million) 11.4.4. Asia Pacific: Market Size and Forecast, By Monitoring Technique , 2021 – 2034 ($ Million) 11.4.5. Asia Pacific: Market Size and Forecast, By Industry , 2021 – 2034 ($ Million) 11.4.6. CHINA 11.4.6.1. China: Market Size and Forecast, By Offering, 2021 – 2034 ($ Million) 11.4.6.2. China: Market Size and Forecast, By Monitoring Process, 2021 – 2034 ($ Million) 11.4.6.3. China: Market Size and Forecast, By Monitoring Technique , 2021 – 2034 ($ Million) 11.4.6.4. China: Market Size and Forecast, By Industry , 2021 – 2034 ($ Million) 11.4.7. JAPAN 11.4.7.1. Japan: Market Size and Forecast, By Offering, 2021 – 2034 ($ Million) 11.4.7.2. Japan: Market Size and Forecast, By Monitoring Process, 2021 – 2034 ($ Million) 11.4.7.3. Japan: Market Size and Forecast, By Monitoring Technique , 2021 – 2034 ($ Million) 11.4.7.4. Japan: Market Size and Forecast, By Industry , 2021 – 2034 ($ Million) 11.4.8. INDIA 11.4.8.1. India: Market Size and Forecast, By Offering, 2021 – 2034 ($ Million) 11.4.8.2. India: Market Size and Forecast, By Monitoring Process, 2021 – 2034 ($ Million) 11.4.8.3. India: Market Size and Forecast, By Monitoring Technique , 2021 – 2034 ($ Million) 11.4.8.4. India: Market Size and Forecast, By Industry , 2021 – 2034 ($ Million) 11.4.9. SOUTH KOREA 11.4.9.1. South Korea: Market Size and Forecast, By Offering, 2021 – 2034 ($ Million) 11.4.9.2. South Korea: Market Size and Forecast, By Monitoring Process, 2021 – 2034 ($ Million) 11.4.9.3. South Korea: Market Size and Forecast, By Monitoring Technique , 2021 – 2034 ($ Million) 11.4.9.4. South Korea: Market Size and Forecast, By Industry , 2021 – 2034 ($ Million) 11.4.10. THAILAND 11.4.10.1. Thailand: Market Size and Forecast, By Offering, 2021 – 2034 ($ Million) 11.4.10.2. Thailand: Market Size and Forecast, By Monitoring Process, 2021 – 2034 ($ Million) 11.4.10.3. Thailand: Market Size and Forecast, By Monitoring Technique , 2021 – 2034 ($ Million) 11.4.10.4. Thailand: Market Size and Forecast, By Industry , 2021 – 2034 ($ Million) 11.4.11. INDONESIA 11.4.11.1. Indonesia: Market Size and Forecast, By Offering, 2021 – 2034 ($ Million) 11.4.11.2. Indonesia: Market Size and Forecast, By Monitoring Process, 2021 – 2034 ($ Million) 11.4.11.3. Indonesia: Market Size and Forecast, By Monitoring Technique , 2021 – 2034 ($ Million) 11.4.11.4. Indonesia: Market Size and Forecast, By Industry , 2021 – 2034 ($ Million) 11.4.12. MALAYSIA 11.4.12.1. Malaysia: Market Size and Forecast, By Offering, 2021 – 2034 ($ Million) 11.4.12.2. Malaysia: Market Size and Forecast, By Monitoring Process, 2021 – 2034 ($ Million) 11.4.12.3. Malaysia: Market Size and Forecast, By Monitoring Technique , 2021 – 2034 ($ Million) 11.4.12.4. Malaysia: Market Size and Forecast, By Industry , 2021 – 2034 ($ Million) 11.4.13. AUSTRALIA 11.4.13.1. Australia: Market Size and Forecast, By Offering, 2021 – 2034 ($ Million) 11.4.13.2. Australia: Market Size and Forecast, By Monitoring Process, 2021 – 2034 ($ Million) 11.4.13.3. Australia: Market Size and Forecast, By Monitoring Technique , 2021 – 2034 ($ Million) 11.4.13.4. Australia: Market Size and Forecast, By Industry , 2021 – 2034 ($ Million) 11.4.14. REST FO ASIA PACIFIC 11.4.14.1. Rest fo Asia Pacific: Market Size and Forecast, By Offering, 2021 – 2034 ($ Million) 11.4.14.2. Rest fo Asia Pacific: Market Size and Forecast, By Monitoring Process, 2021 – 2034 ($ Million) 11.4.14.3. Rest fo Asia Pacific: Market Size and Forecast, By Monitoring Technique , 2021 – 2034 ($ Million) 11.4.14.4. Rest fo Asia Pacific: Market Size and Forecast, By Industry , 2021 – 2034 ($ Million) 11.5. South America 11.5.1. South America: Market Size and Forecast, By Country, 2021 – 2034 ($ Million) 11.5.2. South America: Market Size and Forecast, By Offering, 2021 – 2034 ($ Million) 11.5.3. South America: Market Size and Forecast, By Monitoring Process, 2021 – 2034 ($ Million) 11.5.4. South America: Market Size and Forecast, By Monitoring Technique , 2021 – 2034 ($ Million) 11.5.5. South America: Market Size and Forecast, By Industry , 2021 – 2034 ($ Million) 11.5.6. BRAZIL 11.5.6.1. Brazil: Market Size and Forecast, By Offering, 2021 – 2034 ($ Million) 11.5.6.2. Brazil: Market Size and Forecast, By Monitoring Process, 2021 – 2034 ($ Million) 11.5.6.3. Brazil: Market Size and Forecast, By Monitoring Technique , 2021 – 2034 ($ Million) 11.5.6.4. Brazil: Market Size and Forecast, By Industry , 2021 – 2034 ($ Million) 11.5.7. ARGENTINA 11.5.7.1. Argentina: Market Size and Forecast, By Offering, 2021 – 2034 ($ Million) 11.5.7.2. Argentina: Market Size and Forecast, By Monitoring Process, 2021 – 2034 ($ Million) 11.5.7.3. Argentina: Market Size and Forecast, By Monitoring Technique , 2021 – 2034 ($ Million) 11.5.7.4. Argentina: Market Size and Forecast, By Industry , 2021 – 2034 ($ Million) 11.5.8. REST OF SOUTH AMERICA 11.5.8.1. Rest of South America: Market Size and Forecast, By Offering, 2021 – 2034 ($ Million) 11.5.8.2. Rest of South America: Market Size and Forecast, By Monitoring Process, 2021 – 2034 ($ Million) 11.5.8.3. Rest of South America: Market Size and Forecast, By Monitoring Technique , 2021 – 2034 ($ Million) 11.5.8.4. Rest of South America: Market Size and Forecast, By Industry , 2021 – 2034 ($ Million) 11.6. Middle East & Africa 11.6.1. Middle East & Africa: Market Size and Forecast, By Country, 2021 – 2034 ($ Million) 11.6.2. Middle East & Africa: Market Size and Forecast, By Offering, 2021 – 2034 ($ Million) 11.6.3. Middle East & Africa: Market Size and Forecast, By Monitoring Process, 2021 – 2034 ($ Million) 11.6.4. Middle East & Africa: Market Size and Forecast, By Monitoring Technique , 2021 – 2034 ($ Million) 11.6.5. Middle East & Africa: Market Size and Forecast, By Industry , 2021 – 2034 ($ Million) 11.6.6. SAUDI ARABIA 11.6.6.1. Saudi Arabia: Market Size and Forecast, By Offering, 2021 – 2034 ($ Million) 11.6.6.2. Saudi Arabia: Market Size and Forecast, By Monitoring Process, 2021 – 2034 ($ Million) 11.6.6.3. Saudi Arabia: Market Size and Forecast, By Monitoring Technique , 2021 – 2034 ($ Million) 11.6.6.4. Saudi Arabia: Market Size and Forecast, By Industry , 2021 – 2034 ($ Million) 11.6.7. UAE 11.6.7.1. UAE: Market Size and Forecast, By Offering, 2021 – 2034 ($ Million) 11.6.7.2. UAE: Market Size and Forecast, By Monitoring Process, 2021 – 2034 ($ Million) 11.6.7.3. UAE: Market Size and Forecast, By Monitoring Technique , 2021 – 2034 ($ Million) 11.6.7.4. UAE: Market Size and Forecast, By Industry , 2021 – 2034 ($ Million) 11.6.8. EGYPT 11.6.8.1. Egypt: Market Size and Forecast, By Offering, 2021 – 2034 ($ Million) 11.6.8.2. Egypt: Market Size and Forecast, By Monitoring Process, 2021 – 2034 ($ Million) 11.6.8.3. Egypt: Market Size and Forecast, By Monitoring Technique , 2021 – 2034 ($ Million) 11.6.8.4. Egypt: Market Size and Forecast, By Industry , 2021 – 2034 ($ Million) 11.6.9. SOUTH AFRICA 11.6.9.1. South Africa: Market Size and Forecast, By Offering, 2021 – 2034 ($ Million) 11.6.9.2. South Africa: Market Size and Forecast, By Monitoring Process, 2021 – 2034 ($ Million) 11.6.9.3. South Africa: Market Size and Forecast, By Monitoring Technique , 2021 – 2034 ($ Million) 11.6.9.4. South Africa: Market Size and Forecast, By Industry , 2021 – 2034 ($ Million) 11.6.10. REST OF MIDDLE EAST & AFRICA 11.6.10.1. Rest of Middle East & Africa: Market Size and Forecast, By Offering, 2021 – 2034 ($ Million) 11.6.10.2. Rest of Middle East & Africa: Market Size and Forecast, By Monitoring Process, 2021 – 2034 ($ Million) 11.6.10.3. Rest of Middle East & Africa: Market Size and Forecast, By Monitoring Technique , 2021 – 2034 ($ Million) 11.6.10.4. Rest of Middle East & Africa: Market Size and Forecast, By Industry , 2021 – 2034 ($ Million) CHAPTER 12. Competitive Landscape 12.1. Competitior Benchmarking 2021 12.2. Market Share Analysis 12.3. Key Developments Analysis By Top 5 Companies 12.4. Market Share Acquisition Strategies: Analysis of Key Approaches Employed by Top Players CHAPTER 13. Company Profiles 13.1. Emerson Electric 13.1.1. Business Overview 13.1.2. Financial Analysis 13.1.2.1. Business Segment Revenue, 2018, 2019, 2020, $ Million 13.1.2.2. Geographic Revenue Mix, 2020 (% Share) 13.1.3. Product Portfolio 13.1.4. Recent Development and Strategies Adopted 13.1.5. SWOT Analysis 13.2. General Electric 13.3. Honeywell International 13.4. National Instruments 13.5. Wilcoxon Sensing Technologies 13.6. Rockwell Automation 13.7. PARKER HANNIFIN CORP 13.8. Fluke Corporation 13.9. Meggitt PLC 13.10. Piezotronics

Connect to Analyst

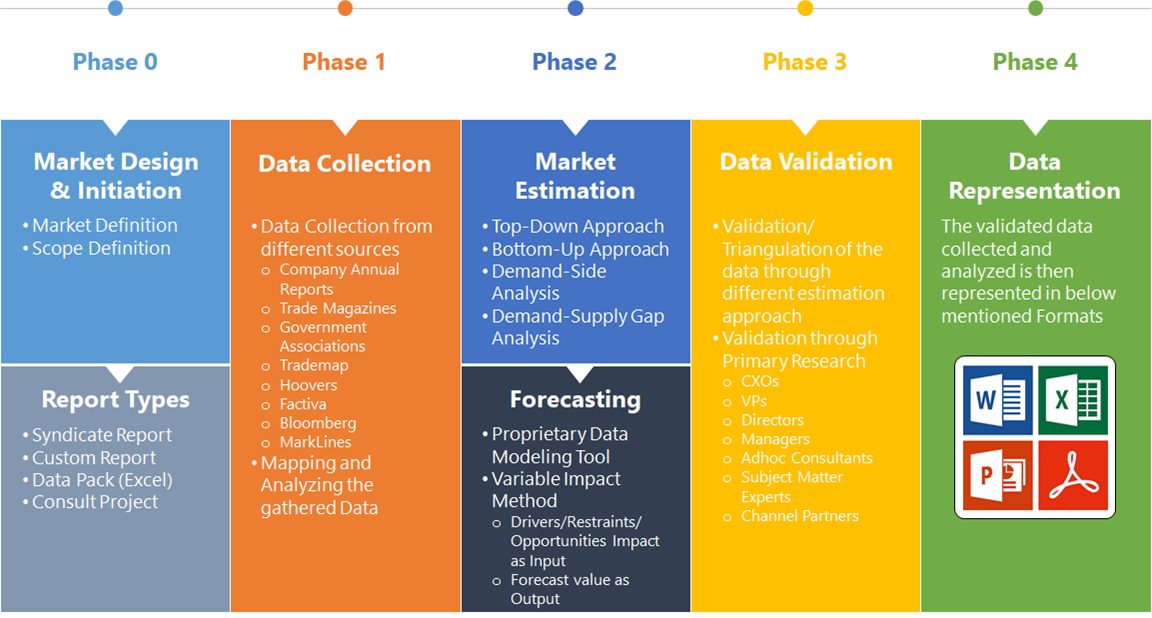

Research Methodology