Global Predictive Maintenance Market Analysis and Global Forecast 2023-2033

€ 1,230.43 – € 4,886.30Price range: € 1,230.43 through € 4,886.30

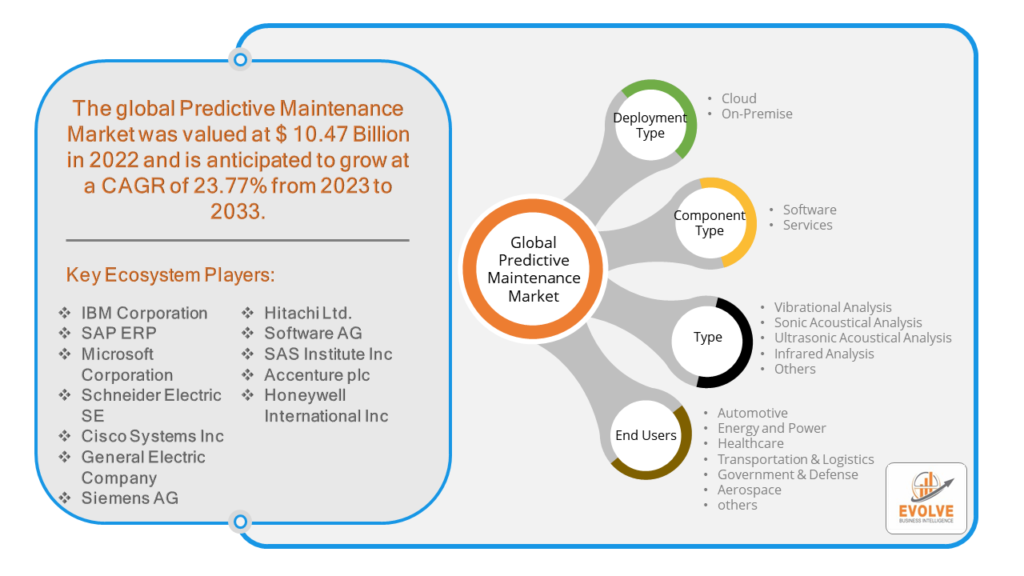

Global Predictive Maintenance Market Research Report: Information By Deployment Type (Cloud and On-Premise), By Component Type (Solutions and Services), By Type (Vibrational Analysis, Sonic Acoustical Analysis, Ultrasonic Acoustical Analysis, Infrared Analysis, and Others) By Organization’s size (Large Enterprise, Small & Medium Enterprise), By End-Users (Automotive, Energy and Power, Healthcare, Transportation & Logistics, Government & Defense, Aerospace, and others), and by Region — Forecast till 2033

Page: 154

Global Predictive Maintenance Market Overview

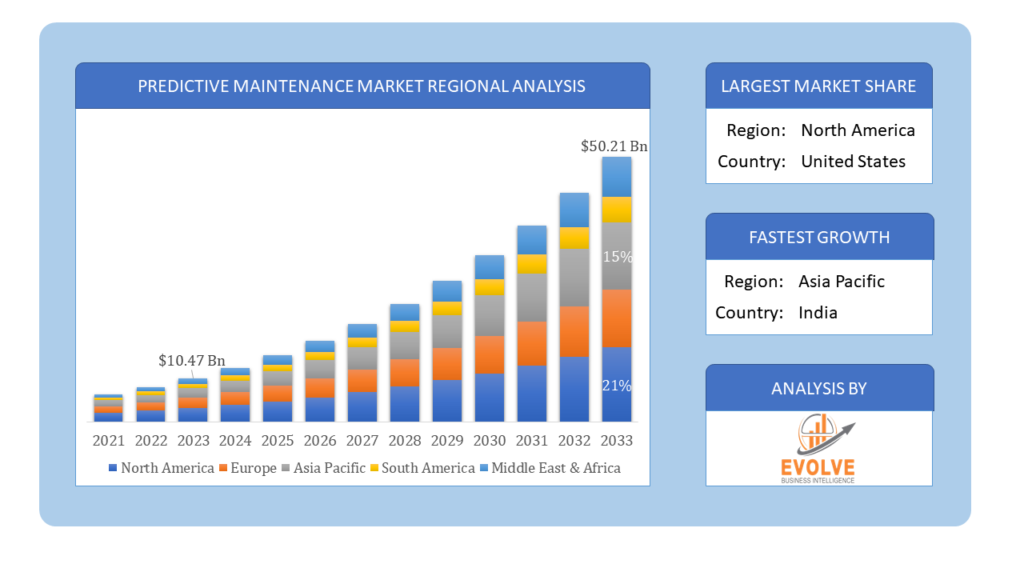

The Global Predictive Maintenance Market Size is expected to reach USD 50.21 Billion by 2033. The Global Predictive Maintenance Market industry size accounted for USD 10.47 Billion in 2023 and is expected to expand at a compound annual growth rate (CAGR) of 23.77% from 2023 to 2033. The Global Predictive Maintenance Market refers to the collective market for technologies, solutions, and services aimed at predicting equipment failures or maintenance needs in various industries. Predictive maintenance utilizes data analytics, machine learning, and sensor technologies to monitor the condition of equipment and predict when maintenance should be performed. By analyzing patterns and trends in equipment behavior, predictive maintenance helps businesses optimize maintenance schedules, reduce downtime, minimize costs, and prevent unexpected equipment failures. This market encompasses a wide range of industries including manufacturing, transportation, energy, healthcare, and more, where proactive maintenance strategies are crucial for efficient operations.

Global Predictive Maintenance Market Synopsis

The COVID-19 pandemic had significant impacts on the Global Predictive Maintenance Market. Many predictive maintenance solutions rely on components or technology that may be sourced from different regions globally. Disruptions in the supply chain due to lockdowns, restrictions on movement, and reduced manufacturing capacity have impacted the availability of these components, potentially delaying projects or hindering new installations. During the height of the pandemic, many businesses faced financial strain, leading to a decrease in capital expenditure budgets. Investments in predictive maintenance solutions may have been postponed or scaled back as companies focused on cost-saving measures and preserving liquidity. The need for remote monitoring and maintenance became more pronounced during the pandemic as travel restrictions and social distancing measures made it challenging for technicians to be physically present on-site. This led to an increased demand for predictive maintenance solutions that could be monitored and managed remotely, driving innovation in this area.

Global Predictive Maintenance Market Dynamics

The major factors that have impacted the growth of Global Predictive Maintenance Market are as follows:

Drivers:

Ø Improved Equipment Performance

By monitoring equipment in real-time and identifying potential issues before they escalate, IIoT-driven predictive maintenance helps optimize equipment performance. This leads to increased uptime, enhanced productivity, and improved product quality, contributing to overall operational efficiency. The development of increasingly sophisticated and affordable sensors has facilitated the widespread adoption of IIoT in industrial settings. These sensors can monitor various parameters such as temperature, vibration, pressure, and fluid levels, providing comprehensive insights into equipment health and performance. IIoT enables remote monitoring and management of equipment, allowing maintenance teams to access real-time data and diagnostics from anywhere with an internet connection. This capability is particularly valuable for organizations with distributed or geographically dispersed assets, as it reduces the need for on-site inspections and troubleshooting.

Restraint:

- Perception of Interoperability Challenges

Predictive maintenance solutions often involve multiple technologies, platforms, and vendors. Ensuring interoperability and seamless integration between these components can be difficult, especially when different systems use proprietary protocols or standards. Interoperability challenges can result in compatibility issues, data loss, or inefficiencies in data exchange. Predictive maintenance solutions rely on collecting and analyzing large volumes of data from industrial equipment and systems. Ensuring the security and privacy of this data is crucial to protect against cyber threats, data breaches, and unauthorized access. Security concerns, such as the risk of cyberattacks or data leaks, may deter organizations from fully embracing predictive maintenance technologies.

Opportunity:

⮚ Predictive Analytics for Complex Systems

AI and ML enable predictive maintenance solutions to analyze complex relationships and interactions within industrial systems. These technologies can detect subtle anomalies or deviations from normal behavior that may indicate impending equipment failures, even in highly interconnected and dynamic environments. AI-driven predictive maintenance solutions can continuously learn from past maintenance activities and equipment performance data to optimize maintenance schedules and strategies. By dynamically adjusting maintenance intervals based on real-time conditions and performance trends, organizations can minimize downtime, extend asset lifespan, and reduce maintenance costs. AI-powered predictive maintenance solutions can not only predict equipment failures but also suggest proactive interventions to prevent or mitigate these issues. By analyzing the root causes of potential failures and recommending corrective actions, organizations can address underlying issues before they escalate into costly downtime or production losses.

Global Predictive Maintenance Market Segment Overview

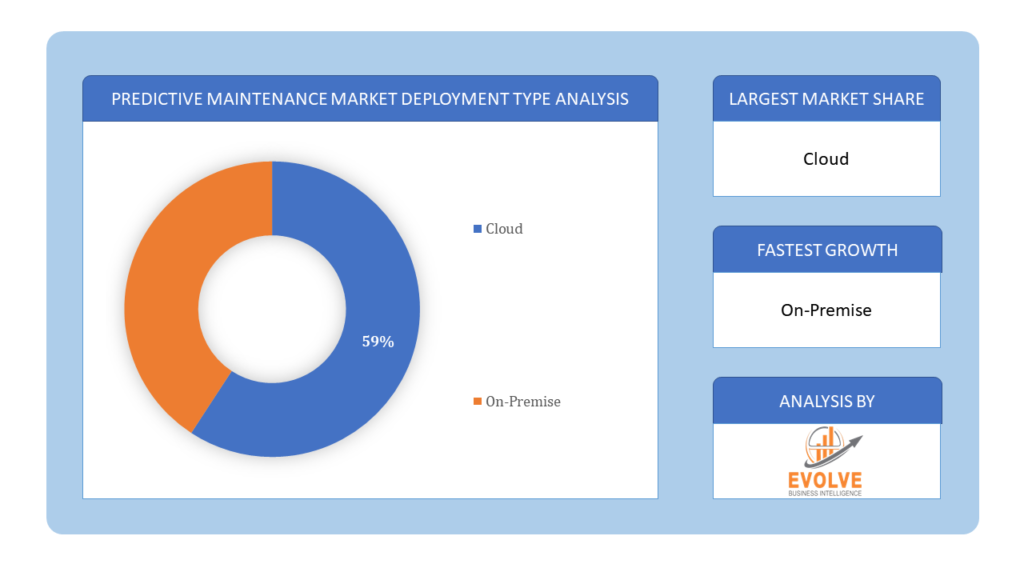

By Deployment Type

Based on Deployment Type, the market is segmented based on Cloud and On-Premise. The cloud segment is dominant the market, due to the fact that the cloud-based services offer businesses the competitive advantages such as remote accessibility, internal data delivery & handling, direct IT control, robust deployment, faster data processing, efficient resource utilization, and cost-effectiveness.

Based on Deployment Type, the market is segmented based on Cloud and On-Premise. The cloud segment is dominant the market, due to the fact that the cloud-based services offer businesses the competitive advantages such as remote accessibility, internal data delivery & handling, direct IT control, robust deployment, faster data processing, efficient resource utilization, and cost-effectiveness.

By Component Type

Based on Component Type, the market segment has been divided into the Solutions and Services. The solution segment dominated the global market. The solution leverages the data accumulated by different IoT sensors and performs an in-depth data analysis for the prediction of an anomaly in the operation of the critical equipment. The growth of this segment is mainly driven by the increasing demand for predictive maintenance market solutions, which minimize unplanned downtime and allows the prolonged life of machinery.

By Type

Based on Type, the market segment has been divided into the Vibrational Analysis, Sonic Acoustical Analysis, Ultrasonic Acoustical Analysis, Infrared Analysis and Others. The Vibrational Analysis segment is anticipated to dominant the market. Vibrational analysis informs maintenance strategies by providing insights into equipment health and performance. Predictive maintenance solutions utilize vibrational data to optimize maintenance schedules, prioritize maintenance activities, and allocate resources effectively. By analyzing vibration trends and historical maintenance data, predictive models can recommend the most appropriate maintenance actions, such as condition-based maintenance, predictive maintenance, or proactive replacements, to maximize equipment reliability and minimize maintenance costs.

By Organization’s Size

Based on Organization’s Size, the market segment has been divided into the Large Enterprise and Small & Medium Enterprise. The Large Enterprise segment is anticipated the market. Large enterprises often face significant risks associated with equipment failures, production disruptions, and regulatory non-compliance. Predictive maintenance solutions enable proactive risk mitigation strategies by identifying potential failure modes, assessing risk probabilities, and prioritizing maintenance activities based on criticality. This helps large enterprises comply with regulatory requirements, mitigate operational risks, and maintain business continuity.

By End Users

Based on End Users, the market segment has been divided into the Automotive, Energy and Power, Healthcare, Transportation & Logistics, Government & Defense, Aerospace and others. The healthcare segment is dominant the market. The predictive maintenance of biomedical devices such as X-ray, MR, tomography, ventilators, and mammography is one of the major concerns to increase decision-making capabilities and optimize operational efficiencies in hospitals.

Global Predictive Maintenance Market Regional Analysis

Based on region, the global Predictive Maintenance Market has been divided into North America, Europe, Asia-Pacific, the Middle East & Africa, and Latin America. North America is projected to dominate the use of the Global Predictive Maintenance Market followed by the Asia-Pacific and Europe regions.

Predictive Maintenance North America Market

Predictive Maintenance North America Market

North America holds a dominant position in the Global Predictive Maintenance Market. United States and Canada countries have advanced industrial sectors and a high level of technological adoption, driving significant demand for predictive maintenance solutions. Industries such as manufacturing, oil & gas, and aerospace are prominent users of predictive maintenance technologies. North America has stringent regulations pertaining to workplace safety and equipment maintenance, which incentivize the adoption of predictive maintenance solutions to ensure compliance and mitigate risks.

Predictive Maintenance Asia-Pacific Market

The Asia-Pacific region has indeed emerged as the fastest-growing market for the Global Predictive Maintenance Market industry. China’s manufacturing sector is a major driver of the predictive maintenance market in the region. The government’s Made in China 2025 initiative and focus on smart manufacturing drive adoption of predictive maintenance technologies. Japan and South Korea countries are known for their advanced manufacturing capabilities and are early adopters of predictive maintenance solutions, particularly in industries like automotive and electronics. Countries such as India and Southeast Asian nations are witnessing rapid industrialization, creating opportunities for predictive maintenance vendors as industries modernize their operations.

Competitive Landscape

The global Predictive Maintenance Market is highly competitive, with numerous players offering a wide range of software solutions. The competitive landscape is characterized by the presence of established companies, as well as emerging startups and niche players. To increase their market position and attract a wide consumer base, the businesses are employing various strategies, such as product launches, and strategic alliances.

Prominent Players:

- IBM Corporation

- SAP ERP

- Microsoft Corporation

- Schneider Electric SE

- Cisco Systems Inc

- General Electric Company

- Siemens AG

- Hitachi Ltd.

- Software AG

- SAS Institute Inc

- Accenture plc

- Honeywell International Inc.

Scope of the Report

Global Predictive Maintenance Market, by Deployment Type

- Cloud

- On-Premise

Global Predictive Maintenance Market, by Component Type

- Solutions

- Services

Global Predictive Maintenance Market, by Type

- Vibrational Analysis

- Sonic Acoustical Analysis

- Ultrasonic Acoustical Analysis

- Infrared Analysis

- Others

Global Predictive Maintenance Market, by Organization’s Size

- Large Enterprise

- Small & Medium Enterprise

Global Predictive Maintenance Market, by End Users

- Automotive

- Energy and Power

- Healthcare

- Transportation & Logistics

- Government & Defense

- Aerospace

- others

Global Predictive Maintenance Market, by Region

- North America

- US

- Canada

- Mexico

- Europe

- UK

- Germany

- France

- Italy

- Spain

- Benelux

- Nordic

- Rest of Europe

- Asia Pacific

- China

- Japan

- South Korea

- Indonesia

- Austalia

- Malaysia

- India

- Rest of Asia Pacific

- South America

- Brazil

- Argentina

- Rest of South America

- Middle East & Africa

- Saudi Arabia

- UAE

- Egypt

- South Africa

- Rest of Middle East & Africa

| Parameters | Indicators |

|---|---|

| Market Size | 2033: $50.21 Billion |

| CAGR | 23.77% CAGR (2023-2033) |

| Base year | 2022 |

| Forecast Period | 2023-2033 |

| Historical Data | 2021 |

| Report Coverage | Revenue Forecast, Competitive Landscape, Growth Factors, and Trends |

| Key Segmentations | Deployment Type, Component Type, Type, Organization’s Size, End Users |

| Geographies Covered | North America, Europe, Asia-Pacific, Latin America, Middle East, Africa |

| Key Vendors | IBM Corporation, SAP ERP, Microsoft Corporation, Schneider Electric SE, Cisco Systems Inc, General Electric Company, Siemens AG, Hitachi Ltd., Software AG, SAS Institute Inc, Accenture plc and Honeywell International Inc.. |

| Key Market Opportunities | • Predictive Analytics for Complex Systems • Proactive Issue Resolution |

| Key Market Drivers | • Improved Equipment Performance • Advancements in Sensor Technology |

REPORT CONTENT BRIEF:

- High-level analysis of the current and future Global Predictive Maintenance Market trends and opportunities

- Detailed analysis of current market drivers, restraining factors, and opportunities in the future

- Global Predictive Maintenance Market historical market size for the year 2021, and forecast from 2023 to 2033

- Global Predictive Maintenance Market share analysis at each product level

- Competitor analysis with detailed insight into its product segment, Government & Defense strength, and strategies adopted.

- Identifies key strategies adopted including product launches and developments, mergers and acquisitions, joint ventures, collaborations, and partnerships as well as funding taken and investment done, among others.

- To identify and understand the various factors involved in the global Predictive Maintenance Market affected by the pandemic

- To provide a detailed insight into the major companies operating in the market. The profiling will include the Government & Defense health of the company’s past 2-3 years with segmental and regional revenue breakup, product offering, recent developments, SWOT analysis, and key strategies.

<p class=”Release”>Press Release</p>

Global Pharmaceutical Manufacturing Market to Reach $1.38 Trillion by 2035 with 7.35% CAGR, New Research Shows

The Global Mammography Market Is Estimated To Record a CAGR of Around 10.29% During The Forecast Period

Glue Stick Market to Reach USD 2.35 Billion by 2034

Podiatry Service Market to Reach USD 11.88 Billion by 2034

Microfluidics Technology Market to Reach USD 32.58 Billion by 2034

Ferric Chloride Market to Reach USD 10.65 Billion by 2034

Family Practice EMR Software Market to Reach USD 21.52 Billion by 2034

Electric Hairbrush Market to Reach USD 15.95 Billion by 2034

Daily Bamboo Products Market to Reach USD 143.52 Billion by 2034

Cross-border E-commerce Logistics Market to Reach USD 112.65 Billion by 2034

Frequently Asked Questions (FAQ)

What is the study period of the Predictive Maintenance Market?

The study period for the Predictive Maintenance Market is from 2023 to 2033.

What is the growth rate of the Predictive Maintenance Market?

The Predictive Maintenance Market is expected to grow at a CAGR of 23.77% from 2023 to 2033.

Which region has the highest growth rate in the Predictive Maintenance Market?

The Asia-Pacific region has the highest growth rate in the Predictive Maintenance Market.

Which region has the largest share of the Predictive Maintenance Market?

North America holds the largest share of the Predictive Maintenance Market.

Who are the key players in the Predictive Maintenance Market?

Key players in the Predictive Maintenance Market include IBM Corporation, SAP ERP, Microsoft Corporation, and Schneider Electric SE.

Do you offer Post sales support?

Yes, we offer 16 hours of analyst support to solve the queries

Do you sell particular sections of a report?

Yes, we provide regional as well as country-level reports. Other than this we also provide a sectional report. Please get in contact with our sales representatives.

Table of Contents

CHAPTER 1. Executive Summary CHAPTER 2. Scope of the Study 2.1. Market Definition 2.2. Market Scope & Segmentation 2.2.1. Objective of Report CHAPTER 3. Evolve BI Methodology 3.1. Data Collection & Validation Approach 3.2. Market Size Estimation and Forecast CHAPTER 4. Exclusive Analysis 4.1. Market Opportunity Score 4.1.1. Deployment Type Segement – Market Opportunity Score 4.1.2. Component Type Segment – Market Opportunity Score 4.1.3. Type Segment – Market Opportunity Score 4.1.4. Organization’s Size Segment – Market Opportunity Score 4.1.5 End Users Segment – Market Opportunity Score 4.2. Key Market Influencing Indicators CHAPTER 5. Market Insights and Trends 5.1. Value Chain Analysis 5.1.1. Raw Material 5.1.2. Manufacturing Process 5.1.3. Distribution Channel 5.1.4. End User 5.2. Porter’s Five Forces Analysis 5.2.1. Bargaining Power of Buyers 5.2.2. Bargaining Power of Suppliers 5.2.3. Threat of New Entrant 5.2.4. Threat of Substitute 5.2.5. Industry Rivalry 5.3. COVID-19 Impact and Post COVID Scenario on Global Predictive Maintenance Market 5.3.1. Impact of COVID-19 5.3.2. Government Support and Industry Revival Policies 5.3.3. Measures Taken by Companies to Mitigate Negative Impact 5.3.4. Post COVID Trend CHAPTER 6. MArket Dynamics 6.1. Introduction 6.2. Drivers 6.2.1. Driver 1 6.2.2. Driver 2 6.2.3. Driver 3 6.3. Restraints 6.3.1. Restraint 1 6.3.2. Restraint 2 6.4. Opportunity 6.4.1. Opportunity 1 CHAPTER 7. Global Predictive Maintenance Market, By Deployment Type 7.1. Introduction 7.1.1. Cloud 7.1.2 On-Premise CHAPTER 8. Global Predictive Maintenance Market, By Component Type 8.1. Introduction 8.1.1. Solutions 8.1.2. Services CHAPTER 9. Global Predictive Maintenance Market, By Type 9.1. Introduction 9.1.1. Vibrational Analysis 9.1.2. Sonic Acoustical Analysis 9.1.3. Ultrasonic Acoustical Analysis 9.1.4. Infrared Analysis 9.1.5 Others sCHAPTER 10. Global Predictive Maintenance Market, By Organization’s Size 10.1.Introduction 10.1.1. Large Enterprise 10.1.2. Small & Medium Enterprise CHAPTER 11. Global Predictive Maintenance Market, By End Users 11.1.Introduction 11.1.1. Automotive 11.1.2. Energy and Power 11.1.3. Healthcare 11.1.4. Transportation & Logistics 11.1.5. Government & Defense 11.1.6 Aerospace 11.1.7 Others CHAPTER 12. Global Predictive Maintenance Market, By Region 12.1. Introduction 12.2. NORTH AMERICA 12.2.1. North America: Market Size and Forecast, By Country, 2023 – 2033 ($ Million) 12.2.2. North America: Market Size and Forecast, By Deployment Type, 2023 – 2033 ($ Million) 12.2.3. North America: Market Size and Forecast, By Component Type, 2023 – 2033 ($ Million) 12.2.4. North America: Market Size and Forecast, By Type, 2023 – 2033 ($ Million) 12.2.5. North America: Market Size and Forecast, By Organization’s Size, 2023 – 2033 ($ Million) 12.2.6. North America: Market Size and Forecast, By End Users, 2023 – 2033 ($ Million) 12.2.6. US 12.2.6.1. US: Market Size and Forecast, By Deployment Type, 2023 – 2033 ($ Million) 12.2.6.2. US: Market Size and Forecast, By Component Type, 2023 – 2033 ($ Million) 12.2.6.3. US: Market Size and Forecast, By Type, 2023 – 2033 ($ Million) 12.2.6.4. US: Market Size and Forecast, By Organization’s Size, 2023 – 2033 ($ Million) 12.2.6.5. US: Market Size and Forecast, By End Users, 2023 – 2033 ($ Million) 12.2.7. CANADA 12.2.7.1. Canada: Market Size and Forecast, By Deployment Type, 2023 – 2033 ($ Million) 12.2.7.2. Canada: Market Size and Forecast, By Component Type, 2023 – 2033 ($ Million) 12.2.7.3. Canada: Market Size and Forecast, By Type, 2023 – 2033 ($ Million) 12.2.7.4. Canada: Market Size and Forecast, By Organization’s Size, 2023 – 2033 ($ Million) 12.2.7.5. Canada: Market Size and Forecast, By End Users, 2023 – 2033 ($ Million) 12.2.8. MEXICO 12.2.8.1. Mexico: Market Size and Forecast, By Deployment Type, 2023 – 2033 ($ Million) 12.2.8.2. Mexico: Market Size and Forecast, By Component Type, 2023 – 2033 ($ Million) 12.2.8.3. Mexico: Market Size and Forecast, By Type, 2023 – 2033 ($ Million) 12.2.8.4. Mexico: Market Size and Forecast, By Organization’s Size, 2023 – 2033 ($ Million) 12.2.8.5. Mexico: Market Size and Forecast, By End Users, 2023 – 2033 ($ Million) 12.3. Europe 12.3.1. Europe: Market Size and Forecast, By Country, 2023 – 2033 ($ Million) 12.3.2. Europe: Market Size and Forecast, By Deployment Type, 2023 – 2033 ($ Million) 12.3.3. Europe: Market Size and Forecast, By Component Type, 2023 – 2033 ($ Million) 12.3.4. Europe: Market Size and Forecast, By Type, 2023 – 2033 ($ Million) 12.3.5. Europe: Market Size and Forecast, By Organization’s Size, 2023 – 2033 ($ Million) 12.3.6. Europe: Market Size and Forecast, By End Users, 2023 – 2033 ($ Million) 12.3.6. U.K. 12.3.6.1. U.K.: Market Size and Forecast, By Deployment Type, 2023 – 2033 ($ Million) 12.3.6.2. U.K.: Market Size and Forecast, By Component Type, 2023 – 2033 ($ Million) 12.3.6.3. U.K.: Market Size and Forecast, By Type, 2023 – 2033 ($ Million) 12.3.6.4. U.K.: Market Size and Forecast, By Organization’s Size, 2023 – 2033 ($ Million) 12.3.6.5. U.K.: Market Size and Forecast, By End Users, 2023 – 2033 ($ Million) 12.3.7. GERMANY 12.3.7.1. Germany: Market Size and Forecast, By Deployment Type, 2023 – 2033 ($ Million) 12.3.7.2. Germany: Market Size and Forecast, By Component Type, 2023 – 2033 ($ Million) 12.3.7.3. Germany: Market Size and Forecast, By Type, 2023 – 2033 ($ Million) 12.3.7.4. Germany: Market Size and Forecast, By Organization’s Size, 2023 – 2033 ($ Million) 12.3.7.5. Germany: Market Size and Forecast, By End Users, 2023 – 2033 ($ Million) 12.3.8. FRANCE 12.3.8.1. France: Market Size and Forecast, By Deployment Type, 2023 – 2033 ($ Million) 12.3.8.2. France: Market Size and Forecast, By Component Type, 2023 – 2033 ($ Million) 12.3.8.3. France: Market Size and Forecast, By Type, 2023 – 2033 ($ Million) 12.3.8.4. France: Market Size and Forecast, By Organization’s Size, 2023 – 2033 ($ Million) 12.3.8.5. France: Market Size and Forecast, By End Users, 2023 – 2033 ($ Million) 12.3.9. ITALY 12.3.9.1. Italy: Market Size and Forecast, By Deployment Type, 2023 – 2033 ($ Million) 12.3.9.2. Italy: Market Size and Forecast, By Component Type, 2023 – 2033 ($ Million) 12.3.9.3. Italy: Market Size and Forecast, By Type, 2023 – 2033 ($ Million) 12.3.9.4. Italy: Market Size and Forecast, By Organization’s Size, 2023 – 2033 ($ Million) 12.3.9.5. Italy: Market Size and Forecast, By End Users, 2023 – 2033 ($ Million) 12.3.10. SPAIN 12.3.10.1. Spain: Market Size and Forecast, By Deployment Type, 2023 – 2033 ($ Million) 12.3.10.2. Spain: Market Size and Forecast, By Component Type, 2023 – 2033 ($ Million) 12.3.10.3. Spain: Market Size and Forecast, By Type, 2023 – 2033 ($ Million) 12.3.10.4. Spain: Market Size and Forecast, By Organization’s Size, 2023 – 2033 ($ Million) 12.3.10.5. Spain: Market Size and Forecast, By End Users, 2023 – 2033 ($ Million) 12.3.11. BENELUX 12.3.11.1. BeNeLux: Market Size and Forecast, By Deployment Type, 2023 – 2033 ($ Million) 12.3.11.2. BeNeLux: Market Size and Forecast, By Component Type, 2023 – 2033 ($ Million) 12.3.11.3. BeNeLux: Market Size and Forecast, By Type, 2023 – 2033 ($ Million) 12.3.11.4. BeNeLux: Market Size and Forecast, By Organization’s Size, 2023 – 2033 ($ Million) 12.3.11.5. BeNeLux: Market Size and Forecast, By End Users, 2023 – 2033 ($ Million) 12.3.12. RUSSIA 12.3.12.1. Russia: Market Size and Forecast, By Deployment Type, 2023 – 2033 ($ Million) 12.3.12.2. Russia: Market Size and Forecast, By Component Type, 2023 – 2033 ($ Million) 12.3.12.3. Russia: Market Size and Forecast, By Type, 2023 – 2033 ($ Million) 12.3.12.4. Russia: Market Size and Forecast, By Organization’s Size, 2023 – 2033 ($ Million) 12.3.12.5. Russia: Market Size and Forecast, By End Users, 2023 – 2033 ($ Million) 12.3.13. REST OF EUROPE 12.3.13.1. Rest of Europe: Market Size and Forecast, By Deployment Type, 2023 – 2033 ($ Million) 12.3.13.2. Rest of Europe: Market Size and Forecast, By Component Type, 2023 – 2033 ($ Million) 12.3.13.3. Rest of Europe: Market Size and Forecast, By Type, 2023 – 2033 ($ Million) 12.3.13.4. Rest of Europe: Market Size and Forecast, By Organization’s Size, 2023 – 2033 ($ Million) 12.3.13.5. Rest of Europe: Market Size and Forecast, By End Users, 2023 – 2033 ($ Million) 12.4. Asia Pacific 12.4.1. Asia Pacific: Market Size and Forecast, By Country, 2023 – 2033 ($ Million) 12.4.2. Asia Pacific: Market Size and Forecast, By Deployment Type, 2023 – 2033 ($ Million) 12.4.3. Asia Pacific: Market Size and Forecast, By Component Type, 2023 – 2033 ($ Million) 12.4.4. Asia Pacific: Market Size and Forecast, By Type, 2023 – 2033 ($ Million) 12.4.5. Asia Pacific: Market Size and Forecast, By Organization’s Size, 2023 – 2033 ($ Million) 12.4.6. Asia Pacific: Market Size and Forecast, By End Users, 2023 – 2033 ($ Million) 12.4.6. CHINA 12.4.6.1. China: Market Size and Forecast, By Deployment Type, 2023 – 2033 ($ Million) 12.4.6.2. China: Market Size and Forecast, By Component Type, 2023 – 2033 ($ Million) 12.4.6.3. China: Market Size and Forecast, By Type, 2023 – 2033 ($ Million) 12.4.6.4. China: Market Size and Forecast, By Organization’s Size, 2023 – 2033 ($ Million) 12.4.6.5. China: Market Size and Forecast, By End Users, 2023 – 2033 ($ Million) 12.4.7. JAPAN 12.4.7.1. Japan: Market Size and Forecast, By Deployment Type, 2023 – 2033 ($ Million) 12.4.7.2. Japan: Market Size and Forecast, By Component Type, 2023 – 2033 ($ Million) 12.4.7.3. Japan: Market Size and Forecast, By Type, 2023 – 2033 ($ Million) 12.4.7.4. Japan: Market Size and Forecast, By Organization’s Size, 2023 – 2033 ($ Million) 12.4.7.5. Japan: Market Size and Forecast, By End Users, 2023 – 2033 ($ Million) 12.4.8. INDIA 12.4.8.1. India: Market Size and Forecast, By Deployment Type, 2023 – 2033 ($ Million) 12.4.8.2. India: Market Size and Forecast, By Component Type, 2023 – 2033 ($ Million) 12.4.8.3. India: Market Size and Forecast, By Type, 2023 – 2033 ($ Million) 12.4.8.4. India: Market Size and Forecast, By Organization’s Size, 2023 – 2033 ($ Million) 12.4.8.5. India: Market Size and Forecast, By End Users, 2023 – 2033 ($ Million) 12.4.9. SOUTH KOREA 12.4.9.1. South Korea: Market Size and Forecast, By Deployment Type, 2023 – 2033 ($ Million) 12.4.9.2. South Korea: Market Size and Forecast, By Component Type, 2023 – 2033 ($ Million) 12.4.9.3. South Korea: Market Size and Forecast, By Type, 2023 – 2033 ($ Million) 12.4.9.4. South Korea: Market Size and Forecast, By Organization’s Size, 2023 – 2033 ($ Million) 12.4.9.5. South Korea: Market Size and Forecast, By End Users, 2023 – 2033 ($ Million) 12.4.10. THAILAND 12.4.10.1. Thailand: Market Size and Forecast, By Deployment Type, 2023 – 2033 ($ Million) 12.4.10.2. Thailand: Market Size and Forecast, By Component Type, 2023 – 2033 ($ Million) 12.4.10.3. Thailand: Market Size and Forecast, By Type, 2023 – 2033 ($ Million) 12.4.10.4. Thailand: Market Size and Forecast, By Organization’s Size, 2023 – 2033 ($ Million) 12.4.10.5. Thailand: Market Size and Forecast, By End Users, 2023 – 2033 ($ Million) 12.4.11. INDONESIA 12.4.11.1. Indonesia: Market Size and Forecast, By Deployment Type, 2023 – 2033 ($ Million) 12.4.11.2. Indonesia: Market Size and Forecast, By Component Type, 2023 – 2033 ($ Million) 12.4.11.3. Indonesia: Market Size and Forecast, By Type, 2023 – 2033 ($ Million) 12.4.11.4. Indonesia: Market Size and Forecast, By Organization’s Size, 2023 – 2033 ($ Million) 12.4.11.5. Indonesia: Market Size and Forecast, By End Users, 2023 – 2033 ($ Million) 12.4.12. MALAYSIA 12.4.12.1. Malaysia: Market Size and Forecast, By Deployment Type, 2023 – 2033 ($ Million) 12.4.12.2. Malaysia: Market Size and Forecast, By Component Type, 2023 – 2033 ($ Million) 12.4.12.3. Malaysia: Market Size and Forecast, By Type, 2023 – 2033 ($ Million) 12.4.12.4. Malaysia: Market Size and Forecast, By Organization’s Size, 2023 – 2033 ($ Million) 12.4.12.5. Malaysia: Market Size and Forecast, By End Users, 2023 – 2033 ($ Million) 12.4.13. AUSTRALIA 12.4.13.1. Australia: Market Size and Forecast, By Deployment Type, 2023 – 2033 ($ Million) 12.4.13.2. Australia: Market Size and Forecast, By Component Type, 2023 – 2033 ($ Million) 12.4.13.3. Australia: Market Size and Forecast, By Type, 2023 – 2033 ($ Million) 12.4.13.4. Australia: Market Size and Forecast, By Organization’s Size, 2023 – 2033 ($ Million) 12.4.13.5. Australia: Market Size and Forecast, By End Users, 2023 – 2033 ($ Million) 12.4.14. REST FO ASIA PACIFIC 12.4.14.1. Rest fo Asia Pacific: Market Size and Forecast, By Deployment Type, 2023 – 2033 ($ Million) 12.4.14.2. Rest fo Asia Pacific: Market Size and Forecast, By Component Type, 2023 – 2033 ($ Million) 12.4.14.3. Rest fo Asia Pacific: Market Size and Forecast, By Type, 2023 – 2033 ($ Million) 12.4.14.4. Rest fo Asia Pacific: Market Size and Forecast, By Organization’s Size, 2023 – 2033 ($ Million) 12.4.14.5. Rest fo Asia Pacific: Market Size and Forecast, By End Users, 2023 – 2033 ($ Million) 12.5. South America 12.5.1. South America: Market Size and Forecast, By Country, 2023 – 2033 ($ Million) 12.5.2. South America: Market Size and Forecast, By Deployment Type, 2023 – 2033 ($ Million) 12.5.3. South America: Market Size and Forecast, By Component Type, 2023 – 2033 ($ Million) 12.5.4. South America: Market Size and Forecast, By Type, 2023 – 2033 ($ Million) 12.5.5. South America: Market Size and Forecast, By Organization’s Size, 2023 – 2033 ($ Million) 12.5.6. South America: Market Size and Forecast, By End Users, 2023 – 2033 ($ Million) 12.5.6. BRAZIL 12.5.6.1. Brazil: Market Size and Forecast, By Deployment Type, 2023 – 2033 ($ Million) 12.5.6.2. Brazil: Market Size and Forecast, By Component Type, 2023 – 2033 ($ Million) 12.5.6.3. Brazil: Market Size and Forecast, By Type, 2023 – 2033 ($ Million) 12.5.6.4. Brazil: Market Size and Forecast, By Organization’s Size, 2023 – 2033 ($ Million) 12.5.6.5. Brazil: Market Size and Forecast, By End Users, 2023 – 2033 ($ Million) 12.5.7. ARGENTINA 12.5.7.1. Argentina: Market Size and Forecast, By Deployment Type, 2023 – 2033 ($ Million) 12.5.7.2. Argentina: Market Size and Forecast, By Component Type, 2023 – 2033 ($ Million) 12.5.7.3. Argentina: Market Size and Forecast, By Type, 2023 – 2033 ($ Million) 12.5.7.4. Argentina: Market Size and Forecast, By Organization’s Size, 2023 – 2033 ($ Million) 12.5.7.5. Argentina: Market Size and Forecast, By End Users, 2023 – 2033 ($ Million) 12.5.8. REST OF SOUTH AMERICA 12.5.8.1. Rest of South America: Market Size and Forecast, By Deployment Type, 2023 – 2033 ($ Million) 12.5.8.2. Rest of South America: Market Size and Forecast, By Component Type, 2023 – 2033 ($ Million) 12.5.8.3. Rest of South America: Market Size and Forecast, By Type, 2023 – 2033 ($ Million) 12.5.8.4. Rest of South America: Market Size and Forecast, By Organization’s Size, 2023 – 2033 ($ Million) 12.5.8.5. Rest of South America: Market Size and Forecast, By End Users, 2023 – 2033 ($ Million) 12.6. Middle East & Africa 12.6.1. Middle East & Africa: Market Size and Forecast, By Country, 2023 – 2033 ($ Million) 12.6.2. Middle East & Africa: Market Size and Forecast, By Deployment Type, 2023 – 2033 ($ Million) 12.6.3. Middle East & Africa: Market Size and Forecast, By Component Type, 2023 – 2033 ($ Million) 12.6.4. Middle East & Africa: Market Size and Forecast, By Type, 2023 – 2033 ($ Million) 12.6.5. Middle East & Africa: Market Size and Forecast, By Organization’s Size, 2023 – 2033 ($ Million) 12.6.6. Middle East & Africa: Market Size and Forecast, By End Users, 2023 – 2033 ($ Million) 12.6.6. SAUDI ARABIA 12.6.6.1. Saudi Arabia: Market Size and Forecast, By Deployment Type, 2023 – 2033 ($ Million) 12.6.6.2. Saudi Arabia: Market Size and Forecast, By Component Type, 2023 – 2033 ($ Million) 12.6.6.3. Saudi Arabia: Market Size and Forecast, By Type, 2023 – 2033 ($ Million) 12.6.6.4. Saudi Arabia: Market Size and Forecast, By Organization’s Size, 2023 – 2033 ($ Million) 12.6.6.5. Saudi Arabia: Market Size and Forecast, By End Users, 2023 – 2033 ($ Million) 12.6.7. UAE 12.6.7.1. UAE: Market Size and Forecast, By Deployment Type, 2023 – 2033 ($ Million) 12.6.7.2. UAE: Market Size and Forecast, By Component Type, 2023 – 2033 ($ Million) 12.6.7.3. UAE: Market Size and Forecast, By Type, 2023 – 2033 ($ Million) 12.6.7.4. UAE: Market Size and Forecast, By Organization’s Size, 2023 – 2033 ($ Million) 12.6.7.5. UAE: Market Size and Forecast, By End Users, 2023 – 2033 ($ Million) 12.6.8. EGYPT 12.6.8.1. Egypt: Market Size and Forecast, By Deployment Type, 2023 – 2033 ($ Million) 12.6.8.2. Egypt: Market Size and Forecast, By Component Type, 2023 – 2033 ($ Million) 12.6.8.3. Egypt: Market Size and Forecast, By Type, 2023 – 2033 ($ Million) 12.6.8.4. Egypt: Market Size and Forecast, By Organization’s Size, 2023 – 2033 ($ Million) 12.6.8.5. Egypt: Market Size and Forecast, By End Users, 2023 – 2033 ($ Million) 12.6.9. SOUTH AFRICA 12.6.9.1. South Africa: Market Size and Forecast, By Deployment Type, 2023 – 2033 ($ Million) 12.6.9.2. South Africa: Market Size and Forecast, By Component Type, 2023 – 2033 ($ Million) 12.6.9.3. South Africa: Market Size and Forecast, By Type, 2023 – 2033 ($ Million) 12.6.9.4. South Africa: Market Size and Forecast, By Organization’s Size, 2023 – 2033 ($ Million) 12.6.9.5. South Africa: Market Size and Forecast, By End Users, 2023 – 2033 ($ Million) 12.6.10. REST OF MIDDLE EAST & AFRICA 12.6.10.1. Rest of Middle East & Africa: Market Size and Forecast, By Deployment Type, 2023 – 2033 ($ Million) 12.6.10.2. Rest of Middle East & Africa: Market Size and Forecast, By Component Type, 2023 – 2033 ($ Million) 12.6.10.3. Rest of Middle East & Africa: Market Size and Forecast, By Type, 2023 – 2033 ($ Million) 12.6.10.4. Rest of Middle East & Africa: Market Size and Forecast, By Organization’s Size, 2023 – 2033 ($ Million) 12.6.10.5. Rest of Middle East & Africa: Market Size and Forecast, By End Users, 2023 – 2033 ($ Million) CHAPTER 13. Competitive Landscape 13.1. Competitior Benchmarking 2023 13.2. Market Share Analysis 13.3. Key Developments Analysis By Top 5 Companies 13.4. Market Share Acquisition Strategies: Analysis of Key Approaches Employed by Top Players CHAPTER 14. Company Profiles 14.1. IBM Corporation 14.1.1. Business Overview 14.1.2. Financial Analysis 14.1.2.1. Business Segment Revenue, 2018, 2019, 2020, $ Million 14.1.2.2. Geographic Revenue Mix, 2020 (% Share) 14.1.3. Product Portfolio 14.1.4. Recent Development and Strategies Adopted 14.1.5. SWOT Analysis 14.2. SAP ERP 14.3. Microsoft Corporation 14.4. Schneider Electric SE 14.5. Cisco Systems Inc 14.6. General Electric Company 14.7. Siemens AG 14.8. Hitachi Ltd. 14.9. Software AG 14.10. SAS Institute Inc 14.11 Accenture plc 14.12 Honeywell International Inc.

Connect to Analyst

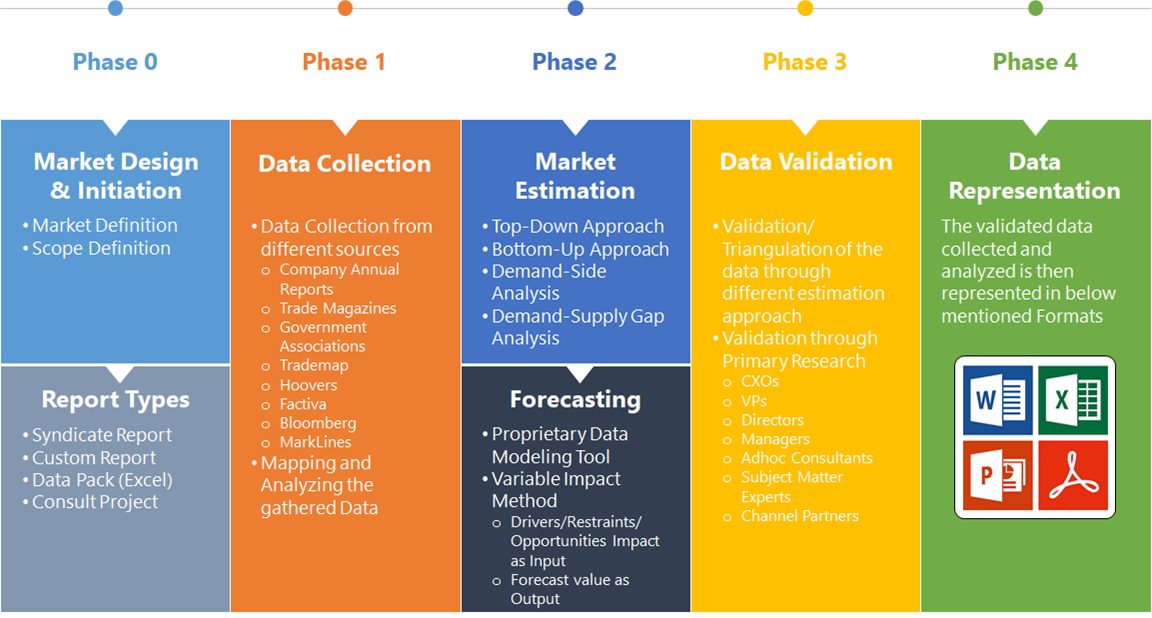

Research Methodology