Manufacturing Predictive Analytics Market Overview

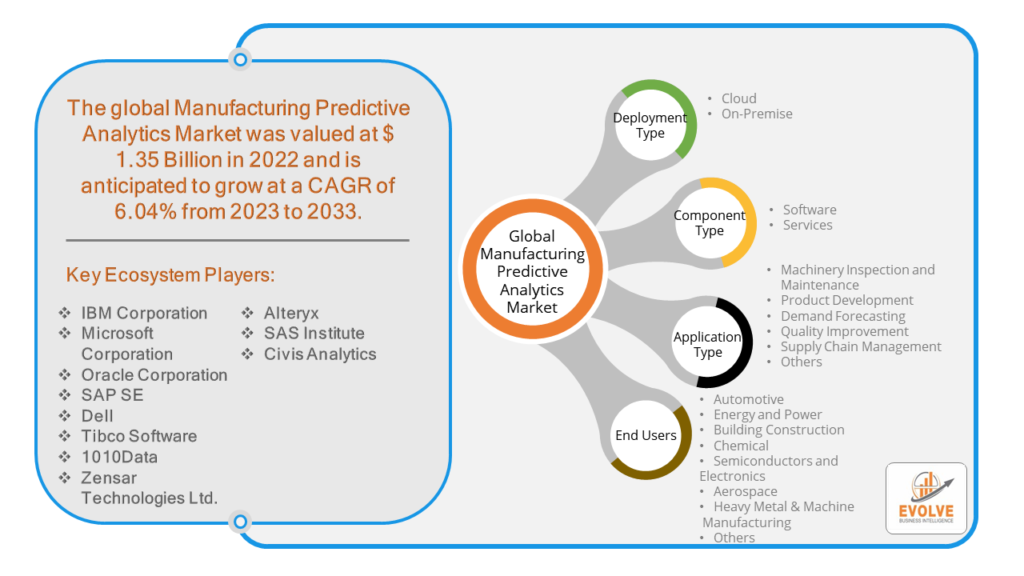

The Manufacturing Predictive Analytics Market Size is expected to reach USD 6.04 Billion by 2033. The Manufacturing Predictive Analytics Market industry size accounted for USD 1.35 Billion in 2023 and is expected to expand at a compound annual growth rate (CAGR) of 17.1% from 2023 to 2033. The Manufacturing Predictive Analytics Market refers to the segment of the analytics industry focused on using data analysis techniques to forecast future outcomes and trends in manufacturing processes. It involves the application of various statistical algorithms, machine learning, and artificial intelligence (AI) technologies to analyze historical and real-time data collected from manufacturing operations.

The market for manufacturing predictive analytics includes software solutions, platforms, and services offered by various technology vendors and consulting firms. Manufacturing predictive analytics can be applied across various stages of the manufacturing process, including supply chain management, production planning, equipment maintenance, quality control, and demand forecasting. By leveraging predictive analytics, manufacturers can optimize their operations, reduce downtime, minimize defects, improve product quality, and enhance overall efficiency.

Global Manufacturing Predictive Analytics Market Synopsis

The COVID-19 pandemic had a significant impact on the Manufacturing Predictive Analytics Market. The pandemic disrupted global supply chains, leading to shortages of raw materials and components. This disruption affected manufacturing operations and highlighted the need for more resilient and flexible supply chain management solutions. Predictive analytics became essential in helping manufacturers anticipate and mitigate supply chain risks, such as identifying alternative suppliers or optimizing inventory levels. The pandemic caused fluctuations in consumer demand across various industries. Manufacturers faced challenges in forecasting demand and aligning production accordingly. Predictive analytics tools helped manufacturers analyze changing consumer behavior patterns, forecast demand more accurately, and adjust production schedules in real-time to meet fluctuating demand levels. The pandemic accelerated the adoption of remote monitoring and control technologies in manufacturing. Predictive analytics platforms enabled manufacturers to remotely monitor equipment performance, analyze data in real-time, and identify potential issues before they escalated. This shift towards remote operations not only helped maintain business continuity during lockdowns but also paved the way for more flexible and decentralized manufacturing models.

Manufacturing Predictive Analytics Market Dynamics

The major factors that have impacted the growth of Manufacturing Predictive Analytics Market are as follows:

Drivers:

Ø Increasing Demand for Operational Efficiency

Manufacturers are under pressure to improve operational efficiency, reduce downtime, and optimize resource utilization. Predictive analytics enables them to analyze vast amounts of data from manufacturing processes, identify inefficiencies, and make data-driven decisions to enhance productivity. The adoption of Industry 4.0 technologies, such as IoT sensors, connected devices, and automation, is transforming manufacturing operations. Predictive analytics complements these technologies by providing insights into equipment performance, predictive maintenance, and process optimization, thus driving the demand for predictive analytics solutions. Predictive maintenance is gaining traction as a cost-effective approach to minimize downtime and reduce maintenance costs. By using predictive analytics to monitor equipment health in real-time and predict potential failures, manufacturers can schedule maintenance activities proactively, optimize asset lifespan, and avoid unplanned downtime.

Restraint:

- Perception of Data Quality and Availability

Predictive analytics relies heavily on data quality and availability. Poor data quality, incomplete datasets, or data silos can limit the accuracy and effectiveness of predictive models. Manufacturers may face challenges in integrating data from disparate sources and ensuring its accuracy and reliability, which can hinder the adoption of predictive analytics solutions. Implementing predictive analytics solutions requires significant upfront investment in technology infrastructure, software licenses, and skilled personnel. Small and medium-sized manufacturers, in particular, may find it challenging to justify the cost of implementation and may be reluctant to adopt predictive analytics due to budget constraints.

Opportunity:

⮚ Growing demand for Predictive Maintenance and Asset Management

Predictive maintenance offers substantial cost savings and efficiency improvements by enabling manufacturers to predict equipment failures before they occur and schedule maintenance activities proactively. There is a growing opportunity for predictive analytics vendors to develop advanced predictive maintenance solutions that leverage machine learning algorithms, IoT sensors, and predictive models to optimize asset management and prolong equipment lifespan. Predictive analytics can help manufacturers improve product quality, reduce defects, and optimize production yields by analyzing data from manufacturing processes, identifying root causes of defects, and implementing corrective actions in real-time. There is an opportunity for predictive analytics vendors to develop solutions tailored to specific industries and applications, such as semiconductor manufacturing, automotive production, and food processing, to address quality control challenges and improve overall product quality.

Manufacturing Predictive Analytics Market Segment Overview

By Deployment Type

Based on Deployment Type, the market is segmented based on Cloud and On-Premise. The cloud-based deployment segment dominates the global manufacturing analytics market because to its scalability, flexibility, and cost-effectiveness. It enables remote data access, real-time decision-making, and collaboration. Manufacturers prioritise digital transformation and adopt cloud technology to improve operational efficiency.

Based on Deployment Type, the market is segmented based on Cloud and On-Premise. The cloud-based deployment segment dominates the global manufacturing analytics market because to its scalability, flexibility, and cost-effectiveness. It enables remote data access, real-time decision-making, and collaboration. Manufacturers prioritise digital transformation and adopt cloud technology to improve operational efficiency.

By Component Type

Based on Component Type, the market segment has been divided into the Software and Services. The Software sector is the fastest growing in the Global Manufacturing Analytics Market, since it provides critical tools for data gathering, analysis, visualization, and decision making. Demand for sophisticated analytics software is growing as digitization and automation progress. Continuous innovation and data-driven decision-making fuel growth, with the Software section serving as the key driver.

By Application Type

Based on Application Type, the market segment has been divided into the Machinery Inspection and Maintenance, Product Development, Demand Forecasting, Quality Improvement, Supply Chain Management and others. The Machinery Inspection and Maintenance segment is dominant the market. Predictive analytics is used to continuously monitor the condition of industrial machinery in real-time. Sensors embedded in machinery collect data on various parameters such as temperature, vibration, pressure, and lubrication levels. Predictive models analyze this data to detect anomalies, identify early signs of equipment degradation, and predict potential failures before they occur. By monitoring machinery health proactively, maintenance activities can be planned and scheduled more efficiently, minimizing downtime and reducing maintenance costs.

By End Users

Based on End Users, the market segment has been divided into the Automotive, Energy and Power, Building Construction, Chemical, Semiconductors and Electronics, Aerospace, Heavy Metal & Machine Manufacturing and others. The Building Construction segment is anticipated to dominant the market. Predictive analytics helps construction companies assess and mitigate risks associated with building projects. By analyzing historical data, weather patterns, project timelines, and other factors, predictive models can identify potential risks such as delays, cost overruns, and safety hazards. This enables proactive risk management strategies to be implemented, reducing the likelihood of disruptions during construction.

Global Manufacturing Predictive Analytics Market Regional Analysis

Based on region, the global Manufacturing Predictive Analytics Market has been divided into North America, Europe, Asia-Pacific, the Middle East & Africa, and Latin America. North America is projected to dominate the use of the Manufacturing Predictive Analytics Market followed by the Asia-Pacific and Europe regions.

Manufacturing Predictive Analytics North America Market

Manufacturing Predictive Analytics North America Market

North America holds a dominant position in the Manufacturing Predictive Analytics Market. North America is a leading region in the adoption of predictive analytics in manufacturing. The presence of a mature manufacturing sector, technological innovation hubs, and a favorable regulatory environment encourages the adoption of advanced analytics solutions. Key players in the region offer predictive analytics solutions tailored to various manufacturing verticals, including automotive, aerospace, electronics, and consumer goods.

Manufacturing Predictive Analytics Asia-Pacific Market

The Asia-Pacific region has indeed emerged as the fastest-growing market for the Manufacturing Predictive Analytics Market industry. The Asia-Pacific region is witnessing rapid growth in manufacturing predictive analytics, fueled by the expansion of manufacturing activities, increasing adoption of Industry 4.0 technologies, and government initiatives to promote digitalization in manufacturing. Countries such as China, Japan, South Korea, and India are investing in advanced analytics solutions to enhance productivity, improve quality, and optimize supply chain operations in key manufacturing sectors such as electronics, automotive, and machinery.

Competitive Landscape

The global Manufacturing Predictive Analytics Market is highly competitive, with numerous players offering a wide range of software solutions. The competitive landscape is characterized by the presence of established companies, as well as emerging startups and niche players. To increase their market position and attract a wide consumer base, the businesses are employing various strategies, such as product launches, and strategic alliances.

Prominent Players:

- IBM Corporation

- Microsoft Corporation

- Oracle Corporation

- SAP SE

- Dell

- Tibco Software

- 1010Data

- Zensar Technologies Ltd.

- Alteryx

- SAS Institute

- Civis Analytics

Key Development

In September 2023, IBM announced that it can assist organisations expedite the capture, computation, and analysis of Scope 3 greenhouse gas (GHG) emissions by integrating NLP into the IBM Envizi ESG Suite. The new text categorization capabilities are intended to assist organisations achieve a significant increase in efficiency and accuracy by automatically ingesting, organising, and managing the spend data needed for emissions calculations and external disclosures.

Scope of the Report

Global Manufacturing Predictive Analytics Market, by Deployment Type

- Cloud

- On-Premise

Global Manufacturing Predictive Analytics Market, by Component Type

- Software

- Services

Global Manufacturing Predictive Analytics Market, by Application Type

- Machinery Inspection and Maintenance

- Product Development

- Demand Forecasting

- Quality Improvement

- Supply Chain Management

- others

Global Manufacturing Predictive Analytics Market, by End Users

- Automotive

- Energy and Power

- Building Construction

- Chemical

- Semiconductors and Electronics

- Aerospace

- Heavy Metal & Machine Manufacturing

- others

Global Manufacturing Predictive Analytics Market, by Region

- North America

- US

- Canada

- Mexico

- Europe

- UK

- Germany

- France

- Italy

- Spain

- Benelux

- Nordic

- Rest of Europe

- Asia Pacific

- China

- Japan

- South Korea

- Indonesia

- Austalia

- Malaysia

- India

- Rest of Asia Pacific

- South America

- Brazil

- Argentina

- Rest of South America

- Middle East & Africa

- Saudi Arabia

- UAE

- Egypt

- South Africa

- Rest of Middle East & Africa

| Parameters | Indicators |

|---|---|

| Market Size | 2033: $6.04 Billion |

| CAGR | 17.1% CAGR (2023-2033) |

| Base year | 2022 |

| Forecast Period | 2023-2033 |

| Historical Data | 2021 |

| Report Coverage | Revenue Forecast, Competitive Landscape, Growth Factors, and Trends |

| Key Segmentations | Deployment Type, Component Type, Application Type, End users |

| Geographies Covered | North America, Europe, Asia-Pacific, Latin America, Middle East, Africa |

| Key Vendors | IBM Corporation, Microsoft Corporation, Oracle Corporation, SAP SE, Dell, Tibco Software, 1010Data, Zensar Technologies Ltd., Alteryx, SAS Institute and Civis Analytics. |

| Key Market Opportunities | • The growing demand for Predictive Maintenance and Asset Management • Enhanced Product Quality and Yield Optimization |

| Key Market Drivers | • Increasing Demand for Operational Efficiency • Focus on Predictive Maintenance |

REPORT CONTENT BRIEF:

- High-level analysis of the current and future Manufacturing Predictive Analytics Market trends and opportunities

- Detailed analysis of current market drivers, restraining factors, and opportunities in the future

- Manufacturing Predictive Analytics Market historical market size for the year 2021, and forecast from 2023 to 2033

- Manufacturing Predictive Analytics Market share analysis at each product level

- Competitor analysis with detailed insight into its product segment, Government & Defense strength, and strategies adopted.

- Identifies key strategies adopted including product launches and developments, mergers and acquisitions, joint ventures, collaborations, and partnerships as well as funding taken and investment done, among others.

- To identify and understand the various factors involved in the global Manufacturing Predictive Analytics Market affected by the pandemic

- To provide a detailed insight into the major companies operating in the market. The profiling will include the Government & Defense health of the company’s past 2-3 years with segmental and regional revenue breakup, product offering, recent developments, SWOT analysis, and key strategies.