Fluoroelastomer Market Analysis and Global Forecast 2023-2033

€ 1,230.43 – € 4,886.30Price range: € 1,230.43 through € 4,886.30

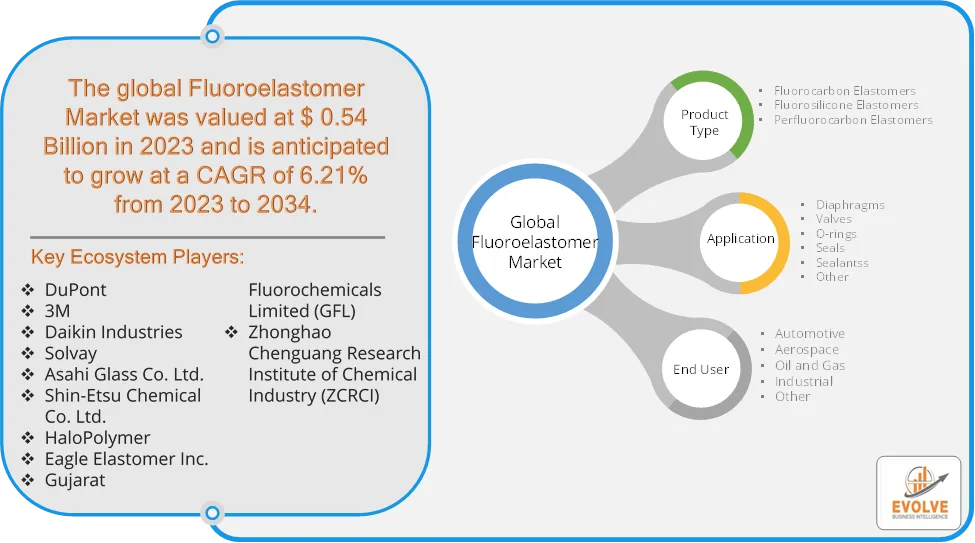

Fluoroelastomer Market Research Report: Information By Product Type (Fluorocarbon Elastomers, Fluorosilicone Elastomers, Perfluorocarbon Elastomers), By Application (Diaphragms, Valves, O-rings, Seals, and Sealants, Other), By End-user (Automotive, Aerospace, Oil and Gas, Industrial, Other), and by Region — Forecast till 2033

Fluoroelastomer Market Overview

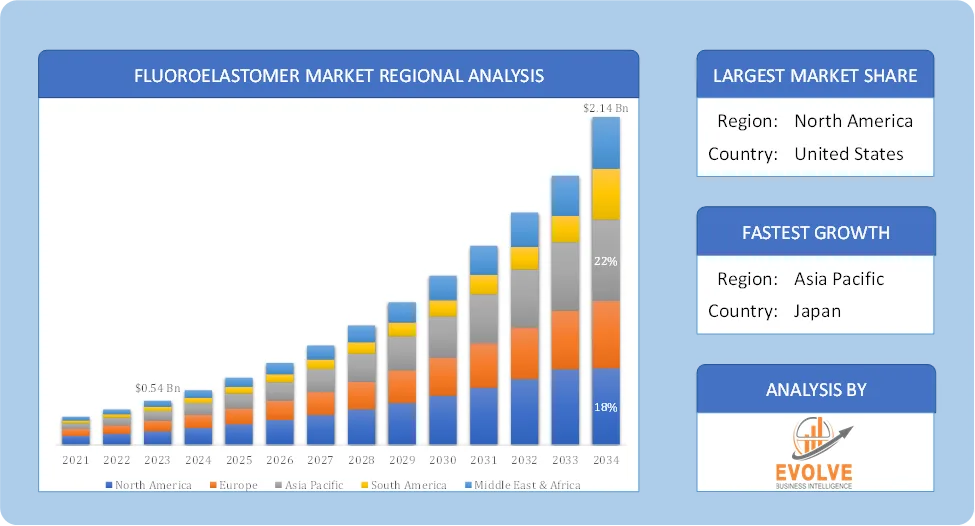

The Fluoroelastomer Market size accounted for USD 0.54 Billion in 2023 and is estimated to account for 0.95 Billion in 2024. The Market is expected to reach USD 2.14 Billion by 2034 growing at a compound annual growth rate (CAGR) of 6.21% from 2024 to 2034. The Fluoroelastomer Market is driven by the increasing demand for high-performance elastomers in industries such as automotive, aerospace, chemical processing, and electronics. Fluoroelastomers are synthetic rubber materials known for their excellent resistance to heat, chemicals, fuels, and oils, making them ideal for applications requiring durability and reliability. Fluoroelastomers are widely used in automotive seals, gaskets, and O-rings due to their high thermal and chemical resistance.

The fluoroelastomer market is poised for continued growth, driven by the increasing demand for high-performance materials in critical applications across various industries.

Global Fluoroelastomer Market Synopsis

Fluoroelastomer Market Dynamics

Fluoroelastomer Market Dynamics

The major factors that have impacted the growth of Fluoroelastomer Market are as follows:

Drivers:

Ø Growing Automotive Industry

Fluoroelastomers are widely used in seals, gaskets, O-rings, and fuel system components due to their resistance to extreme temperatures and aggressive fluids. The shift towards fuel-efficient and hybrid vehicles is increasing the demand for high-performance elastomers. The semiconductor industry requires low-contamination, high-purity elastomers for use in chip manufacturing, plasma etching, and cleanroom applications. Fluoroelastomers provide chemical resistance and thermal stability, essential for semiconductor fabrication and the rise of 5G, IoT, and AI-driven devices is increasing the need for high-performance elastomer components in electronic manufacturing.

Restraint:

- High Production Costs & Expensive Raw Materials

Fluoroelastomers are more expensive than conventional elastomers (e.g., nitrile rubber, silicone rubber) due to their complex manufacturing process and costly raw materials. The cost of fluorinated monomers (such as vinylidene fluoride and tetrafluoroethylene) is high, making fluoroelastomers less accessible for cost-sensitive applications. Price volatility of raw materials due to supply chain disruptions affects market growth.

Opportunity:

⮚ Rising Demand in Electric Vehicles (EVs) & Battery Applications

EVs require high-performance elastomers for battery sealing, cooling systems, and electrical insulation. Fluoroelastomers provide chemical resistance and thermal stability, crucial for lithium-ion battery packs and EV powertrains. Growing EV adoption, driven by government incentives and emission regulations, is fueling demand. Rising demand for biocompatible and sterilization-resistant materials in medical devices. Fluoroelastomers are used in pharmaceutical processing, medical pumps, and diagnostic equipment. Growth in drug manufacturing, biotechnology, and healthcare infrastructure boosts demand.

Fluoroelastomer Market Segment Overview

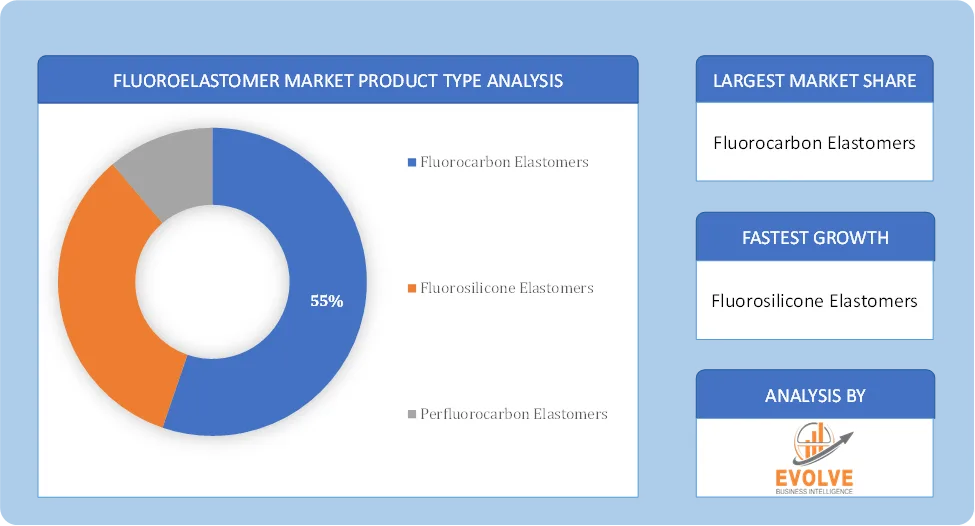

Based on Product Type, the market is segmented based on Fluorocarbon Elastomers, Fluorosilicone Elastomers, Perfluorocarbon Elastomers. The Fluorocarbon Elastomers segment dominant the Fluoroelastomer market due to its excellent resistance to a wide range of chemicals, oils, and high temperatures, making it a preferred choice in critical applications across industries such as automotive, aerospace, and oil and gas.

By Application

Based on Application, the market segment has been divided into Diaphragms, Valves, O-rings, Seals, and Sealants, Other. The Diaphragms segment dominant the Elbow Sleeve market due to the diaphragm’s crucial role in providing effective support, compression, and flexibility for elbow joints, catering to diverse applications in sports, rehabilitation, and medical scenarios.

By End User

Based on End User, the market segment has been divided into the Automotive, Aerospace, Oil and Gas, Industrial, Other. The Automotive segment is the largest segment of the market. The increased demand for fuel-efficient and lightweight vehicles is driving the growth of the automotive segment.

Global Fluoroelastomer Market Regional Analysis

Based on region, the global Fluoroelastomer Market has been divided into North America, Europe, Asia-Pacific, the Middle East & Africa, and Latin America. North America is projected to dominate the use of the Fluoroelastomer Market followed by the Asia-Pacific and Europe regions.

North America Global Fluoroelastomer Market

North America holds a dominant position in the Fluoroelastomer Market. The North American market is driven by demand from the automotive, aerospace, and semiconductor industries. The United States dominates the market due to the presence of major aerospace and automotive manufacturers. High adoption of fluoroelastomers in aircraft engine seals and fuel systems and the growth of the semiconductor industry in the U.S. boosts applications in electronics manufacturing.

Asia-Pacific Global Fluoroelastomer Market

The Asia-Pacific region has indeed emerged as the fastest-growing market for the Fluoroelastomer Market industry. Asia-Pacific dominates the market in terms of growth due to expanding automotive, electronics, and chemical industries. China, Japan, South Korea, and India are key contributors. Booming automotive industry in China and India, increasing demand for fluoroelastomers in engine components, fuel hoses, and gaskets and expanding chemical processing and oil & gas industries in China drive demand for durable elastomers.

Competitive Landscape

The global Fluoroelastomer Market is highly competitive, with numerous players offering a wide range of software solutions. The competitive landscape is characterized by the presence of established companies, as well as emerging startups and niche players. To increase their market position and attract a wide consumer base, the businesses are employing various strategies, such as product launches, and strategic alliances.

Prominent Players:

- DuPont

- 3M

- Daikin Industries

- Solvay

- Asahi Glass Co. Ltd.

- Shin-Etsu Chemical Co. Ltd.

- HaloPolymer

- Eagle Elastomer Inc.

- Gujarat Fluorochemicals Limited (GFL)

- Zhonghao Chenguang Research Institute of Chemical Industry (ZCRCI).

Scope of the Report

Global Fluoroelastomer Market, by Product Type

- Fluorocarbon Elastomers

- Fluorosilicone Elastomers

- Perfluorocarbon Elastomers

Global Fluoroelastomer Market, by Application

- Diaphragms

- Valves

- O-rings

- Seals

- Sealantss

- Other

Global Fluoroelastomer Market, by End User

- Automotive

- Aerospace

- Oil and Gas

- Industrial

- Other

Global Fluoroelastomer Market, by Region

- North America

- US

- Canada

- Mexico

- Europe

- UK

- Germany

- France

- Italy

- Spain

- Benelux

- Nordic

- Rest of Europe

- Asia Pacific

- China

- Japan

- South Korea

- Indonesia

- Austalia

- Malaysia

- India

- Rest of Asia Pacific

- South America

- Brazil

- Argentina

- Rest of SouthAmerica

- Middle East &Africa

- Saudi Arabia

- UAE

- Egypt

- SouthAfrica

- Rest of Middle East & Africa

| Parameters | Indicators |

|---|---|

| Market Size | 2033: USD 2.14 Billion |

| CAGR (2023-2033) | 6.21% |

| Base year | 2022 |

| Forecast Period | 2023-2033 |

| Historical Data | 2021 (2017 to 2020 On Demand) |

| Report Coverage | Revenue Forecast, Competitive Landscape, Growth Factors, and Trends |

| Key Segmentations | Product Type, Application, End User |

| Geographies Covered | North America, Europe, Asia-Pacific, South America, Middle East, Africa |

| Key Vendors | DuPont, 3M, Daikin Industries, Solvay, Asahi Glass Co. Ltd., Shin-Etsu Chemical Co. Ltd., HaloPolymer, Eagle Elastomer Inc., Gujarat Fluorochemicals Limited (GFL) and Zhonghao Chenguang Research Institute of Chemical Industry (ZCRCI). |

| Key Market Opportunities | · Rising Demand in Electric Vehicles (EVs) & Battery Applications · Increasing Use in the Medical & Healthcare Sector |

| Key Market Drivers | · Automotive Industry · Rapid Growth in Semiconductor & Electronics Industrys |

REPORT CONTENT BRIEF:

- High-level analysis of the current and future Fluoroelastomer Market trends and opportunities

- Detailed analysis of current market drivers, restraining factors, and opportunities in the future

- Fluoroelastomer Market historical market size for the year 2021, and forecast from 2023 to 2033

- Fluoroelastomer Market share analysis at each product level

- Competitor analysis with detailed insight into its product segment, Government & Defense strength, and strategies adopted.

- Identifies key strategies adopted including product launches and developments, mergers and acquisitions, joint ventures, collaborations, and partnerships as well as funding taken and investment done, among others.

- To identify and understand the various factors involved in the global Fluoroelastomer Market affected by the pandemic

- To provide a detailed insight into the major companies operating in the market. The profiling will include the Government & Defense health of the company’s past 2-3 years with segmental and regional revenue breakup, product offering, recent developments, SWOT analysis, and key strategies.

Frequently Asked Questions (FAQ)

What is the study period of this market?

The study period of the global Fluoroelastomer Market is 2021- 2033

What is the growth rate of the global Fluoroelastomer Market?

The global Fluoroelastomer Market is growing at a CAGR of 6.21% over the next 10 years

Which region has the highest growth rate in the market of Fluoroelastomer Market?

Asia Pacific is expected to register the highest CAGR during 2023-2033

Which region has the largest share of the global Fluoroelastomer Market?

North America holds the largest share in 2022

Who are the key players in the global Fluoroelastomer Market?

DuPont, 3M, Daikin Industries, Solvay, Asahi Glass Co. Ltd., Shin-Etsu Chemical Co. Ltd., HaloPolymer, Eagle Elastomer Inc., Gujarat Fluorochemicals Limited (GFL) and Zhonghao Chenguang Research Institute of Chemical Industry (ZCRCI). are the major companies operating in the market.

Do you offer Post Sale Support?

Yes, we offer 16 hours of analyst support to solve the queries

Do you sell particular sections of a report?

Yes, we provide regional as well as country-level reports. Other than this we also provide a sectional report. Please get in contact with our sales representatives.

Press Release

Global Pharmaceutical Manufacturing Market to Reach $1.38 Trillion by 2035 with 7.35% CAGR, New Research Shows

The Global Mammography Market Is Estimated To Record a CAGR of Around 10.29% During The Forecast Period

Glue Stick Market to Reach USD 2.35 Billion by 2034

Podiatry Service Market to Reach USD 11.88 Billion by 2034

Microfluidics Technology Market to Reach USD 32.58 Billion by 2034

Ferric Chloride Market to Reach USD 10.65 Billion by 2034

Family Practice EMR Software Market to Reach USD 21.52 Billion by 2034

Electric Hairbrush Market to Reach USD 15.95 Billion by 2034

Daily Bamboo Products Market to Reach USD 143.52 Billion by 2034

Cross-border E-commerce Logistics Market to Reach USD 112.65 Billion by 2034

Table of Content

CHAPTER 1. Executive Summary CHAPTER 2. Scope of the Study 2.1. Market Definition 2.2. Market Scope & Segmentation 2.2.1. Objective of Report CHAPTER 3. Evolve BI Methodology 3.1. Data Collection & Validation Approach 3.2. Market Size Estimation and Forecast CHAPTER 4. Exclusive Analysis 4.1. Market Opportunity Score 4.1.1. Product Type Segement – Market Opportunity Score 4.1.2. Application Segment – Market Opportunity Score 4.1.3. End User Segment – Market Opportunity Score 4.2. Key Market Influencing Indicators CHAPTER 5. Market Insights and Trends 5.1. Value Chain Analysis 5.1.1. Raw Material 5.1.2. Manufacturing Process 5.1.3. Distribution Channel 5.1.4. End User 5.2. Porter’s Five Forces Analysis 5.2.1. Bargaining Power of Buyers 5.2.2. Bargaining Power of Suppliers 5.2.3. Threat of New Entrant 5.2.4. Threat of Substitute 5.2.5. Industry Rivalry 5.3. COVID-19 Impact and Post COVID Scenario on Fluoroelastomer Market 5.3.1. Impact of COVID-19 5.3.2. Government Support and Industry Revival Policies 5.3.3. Measures Taken by Companies to Mitigate Negative Impact 5.3.4. Post COVID Trend CHAPTER 6. Market Dynamics 6.1. Introduction 6.2. Drivers 6.2.1. Driver 1 6.2.2. Driver 2 6.2.3. Driver 3 6.3. Restraints 6.3.1. Restraint 1 6.3.2. Restraint 2 6.4. Opportunity 6.4.1. Opportunity 1 CHAPTER 7. Fluoroelastomer Market, By Product Type 7.1. Introduction 7.1.1. Fluorocarbon Elastomers 7.1.2. Fluorosilicone Elastomers 7.1.3 Perfluorocarbon Elastomers CHAPTER 8 Fluoroelastomer Market, By Application 8.1. Introduction 8.1.1. Valves 8.1.2. O-rings 8.1.3. Seals 8.1.4. Sealants 8.1.5 Diaphragms 8.1.6. Other CHAPTER 9. Fluoroelastomer Market, By End User 9.1. Introduction 9.1.1. Automotive 9.1.2. Aerospace 9.1.3. Oil and Gas 9.1.4. Industrial 9.1.5. Other CHAPTER 10. Fluoroelastomer Market, By Region 10.1. Introduction 10.2. NORTH AMERICA 10.2.1. North America: Market Size and Forecast, By Country, 2024 – 2034($ Million) 10.2.2. North America: Market Size and Forecast, By Product Type, 2024 – 2034($ Million) 10.2.3. North America: Market Size and Forecast, By Application, 2024 – 2034($ Million) 10.2.4. North America: Market Size and Forecast, By End User, 2024 – 2034($ Million) 10.2.5. US 10.2.5.1. US: Market Size and Forecast, By Product Type, 2024 – 2034($ Million) 10.2.5.2. US: Market Size and Forecast, By Application, 2024 – 2034($ Million) 10.2.5.3. US: Market Size and Forecast, By End User, 2024 – 2034($ Million) 10.2.6. CANADA 10.2.6.1. Canada: Market Size and Forecast, By Product Type, 2024 – 2034($ Million) 10.2.6.2. Canada: Market Size and Forecast, By Application, 2024 – 2034($ Million) 10.2.6.3. Canada: Market Size and Forecast, By End User, 2024 – 2034($ Million) 10.2.7. MEXICO 10.2.7.1. Mexico: Market Size and Forecast, By Product Type, 2024 – 2034($ Million) 10.2.7.2. Mexico: Market Size and Forecast, By Application, 2024 – 2034($ Million) 10.2.7.3. Mexico: Market Size and Forecast, By End User, 2024 – 2034($ Million) 10.3. Europe 10.3.1. Europe: Market Size and Forecast, By Country, 2024 – 2034($ Million) 10.3.2. Europe: Market Size and Forecast, By Product Type, 2024 – 2034($ Million) 10.3.3. Europe: Market Size and Forecast, By Application, 2024 – 2034($ Million) 10.3.4. Europe: Market Size and Forecast, By End User, 2024 – 2034($ Million) 10.3.5. U.K. 10.3.5.1. U.K.: Market Size and Forecast, By Product Type, 2024 – 2034($ Million) 10.3.5.2. U.K.: Market Size and Forecast, By Mode of Transport, 2024 – 2034($ Million) 10.3.5.3. U.K.: Market Size and Forecast, By End User, 2024 – 2034($ Million) 10.3.6. GERMANY 10.3.6.1. Germany: Market Size and Forecast, By Product Type, 2024 – 2034($ Million) 10.3.6.2. Germany: Market Size and Forecast, By Application, 2024 – 2034($ Million) 10.3.6.3. Germany: Market Size and Forecast, By End User, 2024 – 2034($ Million) 10.3.7. FRANCE 10.3.7.1. France: Market Size and Forecast, By Service Type, 2024 – 2034($ Million) 10.3.7.2. France: Market Size and Forecast, By Application, 2024 – 2034($ Million) 10.3.7.3. France: Market Size and Forecast, By End User, 2024 – 2034($ Million) 10.3.8. ITALY 10.3.8.1. Italy: Market Size and Forecast, By Product Type, 2024 – 2034($ Million) 10.3.8.2. Italy: Market Size and Forecast, By Application, 2024 – 2034($ Million) 10.3.8.3. Italy: Market Size and Forecast, By End User, 2024 – 2034($ Million) 10.3.9. SPAIN 10.3.9.1. Spain: Market Size and Forecast, By Product Type, 2024 – 2034($ Million) 10.3.9.2. Spain: Market Size and Forecast, By Application, 2024 – 2034($ Million) 10.3.9.3. Spain: Market Size and Forecast, By End User, 2024 – 2034($ Million) 10.3.10. BENELUX 10.3.10.1. BeNeLux: Market Size and Forecast, By Product Type, 2024 – 2034($ Million) 10.3.10.2. BeNeLux: Market Size and Forecast, By Application, 2024 – 2034($ Million) 10.3.10.3. BeNeLux: Market Size and Forecast, By End User, 2024 – 2034($ Million) 10.3.11. RUSSIA 10.3.11.1. Russia: Market Size and Forecast, By Product Type, 2024 – 2034($ Million) 10.3.11.2. Russia: Market Size and Forecast, By Application, 2024 – 2034($ Million) 10.3.11.3. Russia: Market Size and Forecast, By End User, 2024 – 2034($ Million) 10.3.12. REST OF EUROPE 10.3.12.1. Rest of Europe: Market Size and Forecast, By Product Type, 2024 – 2034($ Million) 10.3.12.2. Rest of Europe: Market Size and Forecast, By Application, 2024 – 2034($ Million) 10.3.12.3. Rest of Europe: Market Size and Forecast, By End User, 2024 – 2034($ Million) 10.4. Asia Pacific 10.4.1. Asia Pacific: Market Size and Forecast, By Country, 2024 – 2034($ Million) 10.4.2. Asia Pacific: Market Size and Forecast, By Product Type, 2024 – 2034($ Million) 10.4.3. Asia Pacific: Market Size and Forecast, By Application, 2024 – 2034($ Million) 10.4.4. Asia Pacific: Market Size and Forecast, By End User, 2024 – 2034($ Million) 10.4.5. CHINA 10.4.5.1. China: Market Size and Forecast, By Product Type, 2024 – 2034($ Million) 10.4.5.2. China: Market Size and Forecast, By Application, 2024 – 2034($ Million) 10.4.5.3. China: Market Size and Forecast, By End User, 2024 – 2034($ Million) 10.4.6. JAPAN 10.4.6.1. Japan: Market Size and Forecast, By Service Type, 2024 – 2034($ Million) 10.4.6.2. Japan: Market Size and Forecast, By Application, 2024 – 2034($ Million) 10.4.6.3. Japan: Market Size and Forecast, By End User, 2024 – 2034($ Million) 10.4.7. INDIA 10.4.7.1. India: Market Size and Forecast, By Product Type, 2024 – 2034($ Million) 10.4.7.2. India: Market Size and Forecast, By Application, 2024 – 2034($ Million) 10.4.7.3. India: Market Size and Forecast, By End User, 2024 – 2034($ Million) 10.4.8. SOUTH KOREA 10.4.8.1. South Korea: Market Size and Forecast, By Product Type, 2024 – 2034($ Million) 10.4.8.2. South Korea: Market Size and Forecast, By Application, 2024 – 2034($ Million) 10.4.8.3. South Korea: Market Size and Forecast, By End User, 2024 – 2034($ Million) 10.4.9. THAILAND 10.4.9.1. Thailand: Market Size and Forecast, By Product Type, 2024 – 2034($ Million) 10.4.9.2. Thailand: Market Size and Forecast, By Application, 2024 – 2034($ Million) 10.4.9.3. Thailand: Market Size and Forecast, By End User, 2024 – 2034($ Million) 10.4.10. INDONESIA 10.4.10.1. Indonesia: Market Size and Forecast, By Product Type, 2024 – 2034($ Million) 10.4.10.2. Indonesia: Market Size and Forecast, By Application, 2024 – 2034($ Million) 10.4.10.3. Indonesia: Market Size and Forecast, By End User, 2024 – 2034($ Million) 10.4.11. MALAYSIA 10.4.11.1. Malaysia: Market Size and Forecast, By Product Type, 2024 – 2034($ Million) 10.4.11.2. Malaysia: Market Size and Forecast, By Application, 2024 – 2034($ Million) 10.4.11.3. Malaysia: Market Size and Forecast, By End User, 2024 – 2034($ Million) 10.4.12. AUSTRALIA 10.4.12.1. Australia: Market Size and Forecast, By Product Type, 2024 – 2034($ Million) 10.4.12.2. Australia: Market Size and Forecast, By Application, 2024 – 2034($ Million) 10.4.12.3. Australia: Market Size and Forecast, By End User, 2024 – 2034($ Million) 10.4.13. REST FO ASIA PACIFIC 10.4.13.1. Rest fo Asia Pacific: Market Size and Forecast, By Product Type, 2024 – 2034($ Million) 10.4.13.2. Rest fo Asia Pacific: Market Size and Forecast, By Application, 2024 – 2034($ Million) 10.4.13.3. Rest fo Asia Pacific: Market Size and Forecast, By End User, 2024 – 2034($ Million) 10.5. South America 10.5.1. South America: Market Size and Forecast, By Country, 2024 – 2034($ Million) 10.5.2. South America: Market Size and Forecast, By Product Type, 2024 – 2034($ Million) 10.5.3. South America: Market Size and Forecast, By System, 2024 – 2034($ Million) 10.5.4. South America: Market Size and Forecast, By End User, 2024 – 2034($ Million) 10.5.5. BRAZIL 10.5.5.1. Brazil: Market Size and Forecast, By Product Type, 2024 – 2034($ Million) 10.5.5.2. Brazil: Market Size and Forecast, By Application, 2024 – 2034($ Million) 10.5.5.3. Brazil: Market Size and Forecast, By End User, 2024 – 2034($ Million) 10.5.6. ARGENTINA 10.5.6.1. Argentina: Market Size and Forecast, By Product Type, 2024 – 2034($ Million) 10.5.6.2. Argentina: Market Size and Forecast, By Application, 2024 – 2034($ Million) 10.5.6.3. Argentina: Market Size and Forecast, By End User, 2024 – 2034($ Million) 10.5.7. REST OF SOUTH AMERICA 10.5.7.1. Rest of South America: Market Size and Forecast, By Product Type, 2024 – 2034($ Million) 10.5.7.2. Rest of South America: Market Size and Forecast, By Application, 2024 – 2034($ Million) 10.5.7.3. Rest of South America: Market Size and Forecast, By End User, 2024 – 2034($ Million) 10.6. Middle East & Africa 10.6.1. Middle East & Africa: Market Size and Forecast, By Country, 2024 – 2034($ Million) 10.6.2. Middle East & Africa: Market Size and Forecast, By Product Type, 2024 – 2034($ Million) 10.6.3. Middle East & Africa: Market Size and Forecast, By Application, 2024 – 2034($ Million) 10.6.4. Middle East & Africa: Market Size and Forecast, By End User, 2024 – 2034($ Million) 10.6.5. SAUDI ARABIA 10.6.5.1. Saudi Arabia: Market Size and Forecast, By Product Type, 2024 – 2034($ Million) 10.6.5.2. Saudi Arabia: Market Size and Forecast, By Application, 2024 – 2034($ Million) 10.6.5.3. Saudi Arabia: Market Size and Forecast, By End User, 2024 – 2034($ Million) 10.6.6. UAE 10.6.6.1. UAE: Market Size and Forecast, By Product Type, 2024 – 2034($ Million) 10.6.6.2. UAE: Market Size and Forecast, By Application, 2024 – 2034($ Million) 10.6.6.3. UAE: Market Size and Forecast, By End User, 2024 – 2034($ Million) 10.6.7. EGYPT 10.6.7.1. Egypt: Market Size and Forecast, By Product Type, 2024 – 2034($ Million) 10.6.7.2. Egypt: Market Size and Forecast, By Application, 2024 – 2034($ Million) 10.6.7.3. Egypt: Market Size and Forecast, By End User, 2024 – 2034($ Million) 10.6.8. SOUTH AFRICA 10.6.8.1. South Africa: Market Size and Forecast, By Product Type, 2024 – 2034($ Million) 10.6.8.2. South Africa: Market Size and Forecast, By Application, 2024 – 2034($ Million) 10.6.8.3. South Africa: Market Size and Forecast, By End User, 2024 – 2034($ Million) 10.6.9. REST OF MIDDLE EAST & AFRICA 10.6.9.1. Rest of Middle East & Africa: Market Size and Forecast, By Product Type, 2024 – 2034($ Million) 10.6.9.2. Rest of Middle East & Africa: Market Size and Forecast, By Application, 2024 – 2034($ Million) 10.6.9.3.Rest of Middle East & Africa: Market Size and Forecast, By End User, 2024 – 2034($ Million) CHAPTER 12. Competitive Landscape 12.1. Competitior Benchmarking 2023- 12.2. Market Share Analysis 12.3. Key Developments Analysis By Top 5 Companies 12.4. Market Share Acquisition Strategies: Analysis of Key Approaches Employed by Top Players CHAPTER 13. Company Profiles 13.1. DuPont 13.1.1. Hanon Systems 13.1.2. Financial Analysis 13.1.2.1. Business Segment Revenue, 2020, 2021, 2022, $ Million 13.1.2.2. Geographic Revenue Mix, 2022 (% Share) 13.1.3. Product Portfolio 13.1.4. Recent Development and Strategies Adopted 13.1.5. SWOT Analysis 13.2. 3M 13.3. Daikin Industries 13.4. Solvay 13.5. Shin-Etsu Chemical Co. Ltd. 13.6. HaloPolymer 13.7. Eagle Elastomer Inc. 13.8. Gujarat Fluorochemicals Limited (GFL) 13.9 Zhonghao Chenguang Research Institute of Chemical Industry (ZCRCI). 13.10 Asahi Glass Co. Ltd.

Connect to Analyst

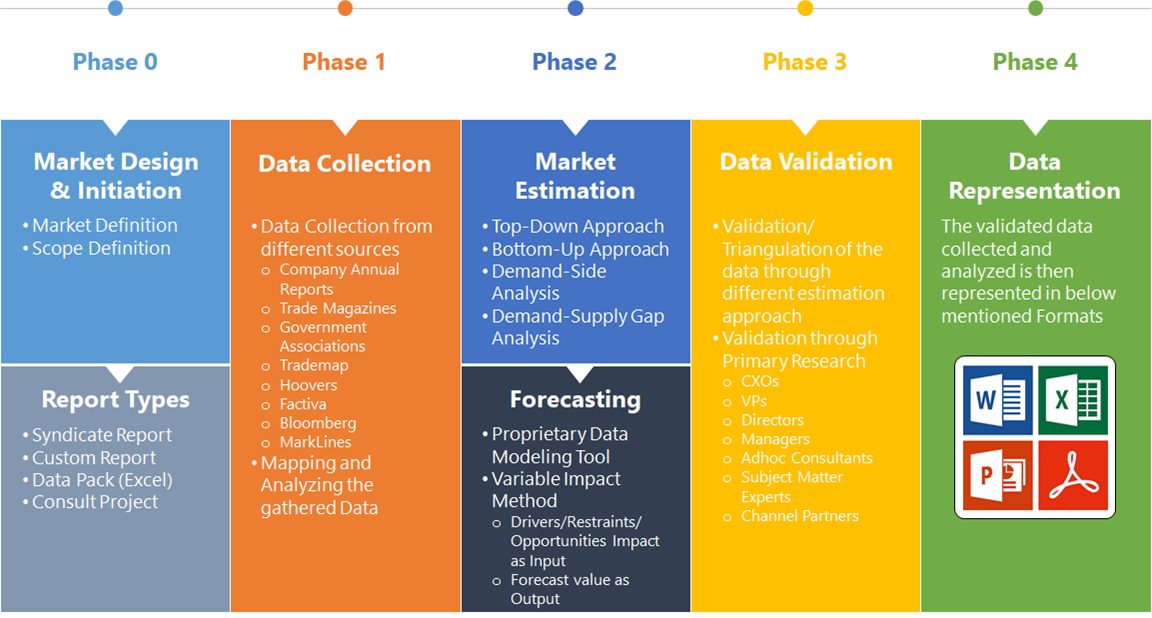

Research Methodology