Distributed Manufacturing Market Analysis and Global Forecast 2023-2033

€ 1,230.43 – € 4,886.30Price range: € 1,230.43 through € 4,886.30

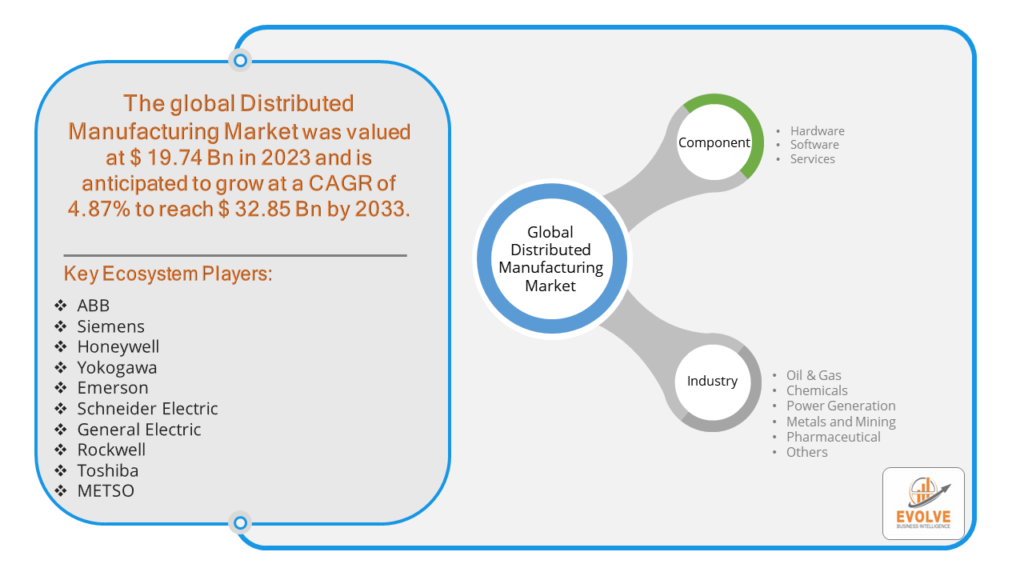

Distributed Manufacturing Market Research Report: Information By Industry (Oil & Gas, Chemicals, Power Generation, Metals and Mining, Pharmaceutical, Others), By Component (Hardware, Software, Services), and by Region — Forecast till 2033

Page: 169

Distributed Manufacturing Market Overview

The Distributed Manufacturing Market Size is expected to reach USD 32.85 Billion by 2033. The Distributed Manufacturing Market industry size accounted for USD 19.74 Billion in 2023 and is expected to expand at a compound annual growth rate (CAGR) of 4.87% from 2023 to 2033. The Distributed Manufacturing Market refers to a production approach where manufacturing processes are decentralized, and products are fabricated closer to the end consumers. This market leverages advanced technologies, such as digital manufacturing, 3D printing, and networked production facilities, to produce goods on-demand, reducing the need for large central factories and extensive supply chains.

Overall, the Distributed Manufacturing Market represents a shift towards more adaptable, efficient, and sustainable production methods, driven by technological advancements and changing consumer demands.

Global Distributed Manufacturing Market Synopsis

The The COVID-19 pandemic significantly impacted the Distributed Manufacturing Market. The disruption of global supply chains highlighted the vulnerabilities of centralized manufacturing, leading to a faster adoption of distributed manufacturing as a more resilient alternative. With international shipping delays and restrictions, there was a greater emphasis on local production to meet immediate needs, boosting the distributed manufacturing market. The ability to quickly adapt and produce customized products locally became crucial during the pandemic, especially for healthcare supplies like PPE and ventilator parts. The pandemic spurred innovation and investment in technologies such as 3D printing, IoT, and automation, which are key enablers of distributed manufacturing. The reduction in transportation and associated carbon emissions aligned with increasing environmental awareness, further promoting distributed manufacturing as a sustainable option. The pandemic underscored the importance of building resilient and agile manufacturing systems, leading to a long-term strategic shift towards distributed manufacturing.

Distributed Manufacturing Market Dynamics

The major factors that have impacted the growth of Distributed Manufacturing Market are as follows:

Drivers:

Ø Technological Advancements

Advances in 3D printing technologies enable cost-effective, on-demand production of complex and customized parts, reducing the need for centralized manufacturing. The integration of digital tools, IoT, and automation enhances the efficiency and scalability of distributed manufacturing processes. Robotics and automation facilitate precise and consistent production, improving productivity and reducing labor costs. Localized production minimizes transportation distances, resulting in lower carbon emissions and a smaller environmental footprint. On-demand and additive manufacturing processes can significantly reduce material waste compared to traditional subtractive manufacturing methods.

Restraint:

- Perception of Technical and Operational Challenges

Ensuring consistent product quality across decentralized manufacturing units can be challenging, especially with varying capabilities and standards. The need for skilled labor and technical expertise to operate advanced manufacturing technologies like 3D printing and IoT can be a barrier, particularly in less developed regions. Integrating distributed manufacturing systems with existing supply chains and IT infrastructure can be complex and costly. Setting up distributed manufacturing facilities and acquiring advanced manufacturing technologies can require significant capital investment.

Opportunity:

⮚ Economic and Operational Efficiency

Small and medium-sized enterprises (SMEs) can benefit from reduced initial capital investment and lower operational costs associated with distributed manufacturing technologies. Distributed manufacturing enhances supply chain resilience and flexibility, allowing businesses to quickly adapt to changing market conditions and disruptions. Implementing Industry 4.0 technologies, such as IoT, blockchain, and digital twins, can enhance the efficiency, transparency, and traceability of distributed manufacturing processes. Creating digital platforms and marketplaces for distributed manufacturing services can facilitate access to new customers, streamline order processing, and enhance customer engagement.

Distributed Manufacturing Market Segment Overview

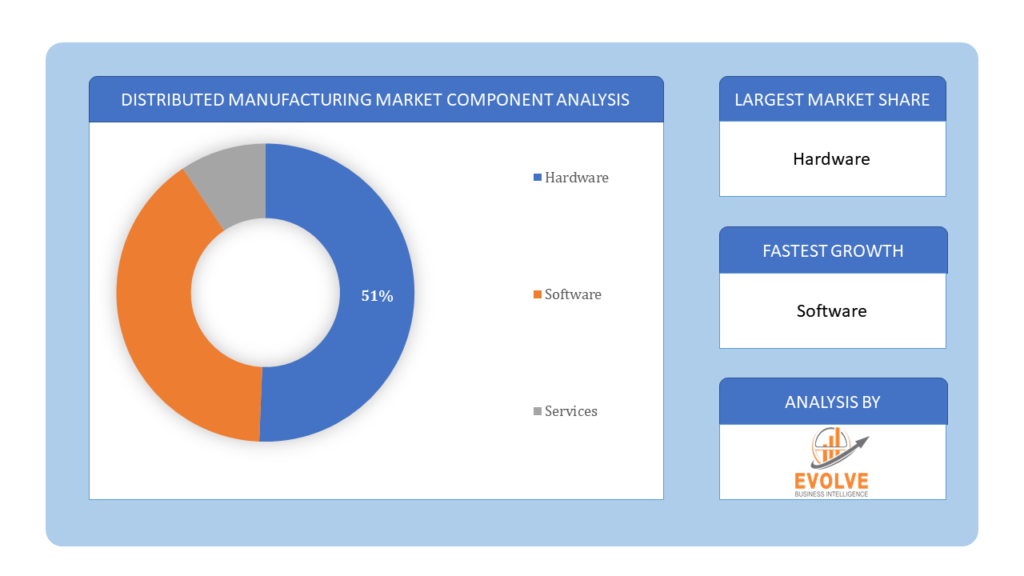

By Component

Based on Component, the market is segmented based on Hardware, Software and Services. This segment includes advanced manufacturing technologies, machinery, and tools that enable decentralized production processes. The encompasses various physical components and devices essential for implementing distributed manufacturing systems

Based on Component, the market is segmented based on Hardware, Software and Services. This segment includes advanced manufacturing technologies, machinery, and tools that enable decentralized production processes. The encompasses various physical components and devices essential for implementing distributed manufacturing systems

By Industry

Based on Industry, the market segment has been divided into the Oil & Gas, Chemicals, Power Generation, Metals and Mining, Pharmaceutical and Others. The Power Generation segment dominant the market. The market plays a crucial role in shaping the future of energy production, offering sustainable, reliable, and resilient power solutions across various applications and regions.

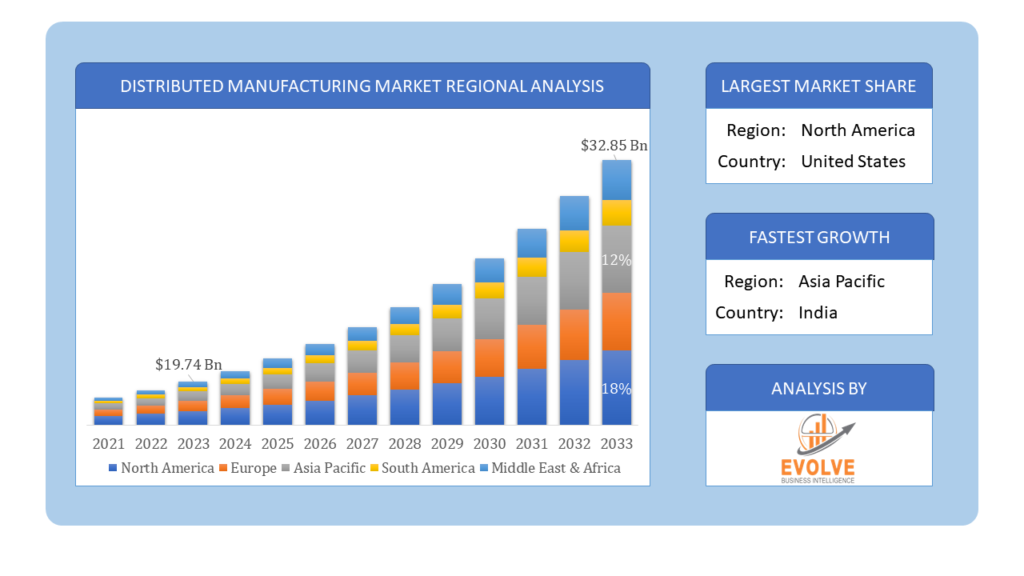

Global Distributed Manufacturing Market Regional Analysis

Based on region, the global Distributed Manufacturing Market has been divided into North America, Europe, Asia-Pacific, the Middle East & Africa, and Latin America. North America is projected to dominate the use of the Distributed Manufacturing Market followed by the Asia-Pacific and Europe regions.

Distributed Manufacturing North America Market

Distributed Manufacturing North America Market

North America holds a dominant position in the Distributed Manufacturing Market. North America, particularly the United States, is a leader in adopting advanced manufacturing technologies such as 3D printing, IoT, and AI. Strong demand from the healthcare and aerospace sectors drives the adoption of distributed manufacturing for customized medical devices and aerospace components. A well-developed ecosystem of research institutions, technology providers, and startups supports innovation and growth in distributed manufacturing.

Distributed Manufacturing Asia-Pacific Market

The Asia-Pacific region has indeed emerged as the fastest-growing market for the Distributed Manufacturing Market industry. Countries like China, Japan, and South Korea are rapidly adopting advanced manufacturing technologies, driven by strong government support and investment. The region’s large manufacturing base and emphasis on production efficiency provide significant opportunities for distributed manufacturing. High demand in the electronics and consumer goods sectors drives the adoption of distributed manufacturing for customized and on-demand production.

Competitive Landscape

The global Distributed Manufacturing Market is highly competitive, with numerous players offering a wide range of software solutions. The competitive landscape is characterized by the presence of established companies, as well as emerging startups and niche players. To increase their market position and attract a wide consumer base, the businesses are employing various strategies, such as product launches, and strategic alliances.

Prominent Players:

- ABB

- Siemens

- Honeywell

- Yokogawa

- Emerson

- Schneider Electric

- General Electric

- Rockwell

- Toshiba

- METSO

Scope of the Report

Global Distributed Manufacturing Market, by Component

- Hardware

- Software

- Services

Global Distributed Manufacturing Market, by Industry

- Oil & Gas

- Chemicals

- Power Generation

- Metals and Mining

- Pharmaceutical

- Others

Global Distributed Manufacturing Market, by Region

- North America

- US

- Canada

- Mexico

- Europe

- UK

- Germany

- France

- Italy

- Spain

- Benelux

- Nordic

- Rest of Europe

- Asia Pacific

- China

- Japan

- South Korea

- Indonesia

- Austalia

- Malaysia

- India

- Rest of Asia Pacific

- South America

- Brazil

- Argentina

- Rest of South America

- Middle East & Africa

- Saudi Arabia

- UAE

- Egypt

- South Africa

- Rest of Middle East & Africa

| Parameters | Indicators |

|---|---|

| Market Size | 2033: $32.85 Billion/strong> |

| CAGR | 4.87% CAGR (2023-2033) |

| Base year | 2022 |

| Forecast Period | 2023-2033 |

| Historical Data | 2021 |

| Report Coverage | Revenue Forecast, Competitive Landscape, Growth Factors, and Trends |

| Key Segmentations | Component, Industry |

| Geographies Covered | North America, Europe, Asia-Pacific, Latin America, Middle East, Africa |

| Key Vendors | ABB, Siemens, Honeywell, Yokogawa, Emerson, Schneider Electric, General Electric, Rockwell, Toshiba and METSO |

| Key Market Opportunities | • The growing demand for healthier food options • The rise of e-commerce and online food delivery platforms |

| Key Market Drivers | • Technological Advancements • Environmental and Sustainability Concerns |

REPORT CONTENT BRIEF:

- High-level analysis of the current and future Distributed Manufacturing Market trends and opportunities

- Detailed analysis of current market drivers, restraining factors, and opportunities in the future

- Distributed Manufacturing Market historical market size for the year 2021, and forecast from 2023 to 2033

- Distributed Manufacturing Market share analysis at each product level

- Competitor analysis with detailed insight into its product segment, Government & Defense strength, and strategies adopted.

- Identifies key strategies adopted including product launches and developments, mergers and acquisitions, joint ventures, collaborations, and partnerships as well as funding taken and investment done, among others.

- To identify and understand the various factors involved in the global Distributed Manufacturing Market affected by the pandemic

- To provide a detailed insight into the major companies operating in the market. The profiling will include the Government & Defense health of the company’s past 2-3 years with segmental and regional revenue breakup, product offering, recent developments, SWOT analysis, and key strategies.

Press Release

Global Pharmaceutical Manufacturing Market to Reach $1.38 Trillion by 2035 with 7.35% CAGR, New Research Shows

The Global Mammography Market Is Estimated To Record a CAGR of Around 10.29% During The Forecast Period

Glue Stick Market to Reach USD 2.35 Billion by 2034

Podiatry Service Market to Reach USD 11.88 Billion by 2034

Microfluidics Technology Market to Reach USD 32.58 Billion by 2034

Ferric Chloride Market to Reach USD 10.65 Billion by 2034

Family Practice EMR Software Market to Reach USD 21.52 Billion by 2034

Electric Hairbrush Market to Reach USD 15.95 Billion by 2034

Daily Bamboo Products Market to Reach USD 143.52 Billion by 2034

Cross-border E-commerce Logistics Market to Reach USD 112.65 Billion by 2034

Frequently Asked Questions (FAQ)

1.What is the study period of this market?

- The study period of the global Distributed Manufacturing Market is 2021- 2033

2.What is the growth rate of the global Distributed Manufacturing Market?

- The global Distributed Manufacturing Market is growing at a CAGR of 4.87% over the next 10 years

3.Which region has the highest growth rate in the market of Distributed Manufacturing Market?

- Asia Pacific is expected to register the highest CAGR during 2023-2033

4.Which region has the largest share of the global Distributed Manufacturing Market?

- North America holds the largest share in 2022

5.Who are the key players in the global Distributed Manufacturing Market?

ABB, Siemens, Honeywell, Yokogawa, Emerson, Schneider Electric, General Electric, Rockwell, Toshiba and METSO. are the major companies operating in the market

6.Do you offer Post Sale Support?

- Yes, we offer 16 hours of analyst support to solve the queries

7.Do you sell particular sections of a report?

Yes, we provide regional as well as country-level reports. Other than this we also provide a sectional report. Please get in contact with our sales representatives

Table of Content

Chapter 1. Executive Summary Chapter 2. Scope Of The Study 2.1. Market Definition 2.2. Scope Of The Study 2.2.1. Objectives of Report 2.2.2. Limitations 2.3. Market Structure Chapter 3. Evolve BI Methodology Chapter 4. Market Insights and Trends 4.1. Supply/ Value Chain Analysis 4.1.1. Raw End Users Providers 4.1.2. Manufacturing Process 4.1.3. Distributors/Retailers 4.1.4. End-Use Industry 4.2. Porter’s Five Forces Analysis 4.2.1. Threat Of New Entrants 4.2.2. Bargaining Power Of Buyers 4.2.3. Bargaining Power Of Suppliers 4.2.4. Threat Of Substitutes 4.2.5. Industry Rivalry 4.3. Impact Of COVID-19 on the Distributed Manufacturing Market 4.3.1. Impact on Market Size 4.3.2. End-Use Industry Trend, Preferences, and Budget Impact 4.3.3. Regulatory Framework/Government Policies 4.3.4. Key Players' Strategy to Tackle Negative Impact 4.3.5. Opportunity Window 4.4. Technology Overview 12.28. Macro factor 4.6. Micro Factor 4.7. Demand Supply Gap Analysis of the Distributed Manufacturing Market 4.8. Import Analysis of the Distributed Manufacturing Market 4.9. Export Analysis of the Distributed Manufacturing Market Chapter 5. Market Dynamics 5.1. Introduction 5.2. DROC Analysis 5.2.1. Drivers 5.2.2. Restraints 5.2.3. Opportunities 5.2.4. Challenges 5.3. Patent Analysis 5.4. Industry Roadmap 5.5. Parent/Peer Market Analysis Chapter 6. Global Distributed Manufacturing Market, By Component 6.1. Introduction 6.2. Hardware 6.3. Software 6.4. Services Chapter 7. Global Distributed Manufacturing Market, By Industry 7.1. Introduction 7.2. Oil & Gas 7.3. Chemicals 7.4 Power Generation 7.5 Metals and Mining 7.6 Pharmaceutical 7.7 Others Chapter 8. Global Distributed Manufacturing Market, By Region 8.1. Introduction 8.2. North America 8.2.1. Introduction 8.2.2. Driving Factors, Opportunity Analyzed, and Key Trends 8.2.3. Market Size and Forecast, By Country, 2023-2033 8.2.4. Market Size and Forecast, By Product Type, 2023-2033 8.2.5. Market Size and Forecast, By End User, 2023-2033 8.2.6. US 8.2.6.1. Introduction 8.2.6.2. Driving Factors, Opportunity Analyzed, and Key Trends 8.2.6.3. Market Size and Forecast, By Product Type, 2023-2033 8.2.6.4. Market Size and Forecast, By End User, 2023-2033 8.2.7. Canada 8.2.7.1. Introduction 8.2.7.2. Driving Factors, Opportunity Analyzed, and Key Trends 8.2.7.4. Market Size and Forecast, By Product Type, 2023-2033 8.2.7.5. Market Size and Forecast, By End User, 2023-2033 8.3. Europe 8.3.1. Introduction 8.3.2. Driving Factors, Opportunity Analyzed, and Key Trends 8.3.3. Market Size and Forecast, By Country, 2023-2033 8.3.4. Market Size and Forecast, By Product Type, 2023-2033 8.3.5. Market Size and Forecast, By End User, 2023-2033 8.3.6. Germany 8.3.6.1. Introduction 8.3.6.2. Driving Factors, Opportunity Analyzed, and Key Trends 8.3.6.3. Market Size and Forecast, By Product Type, 2023-2033 8.3.6.4. Market Size and Forecast, By End User, 2023-2033 8.3.7. France 8.3.7.1. Introduction 8.3.7.2. Driving Factors, Opportunity Analyzed, and Key Trends 8.3.7.3. Market Size and Forecast, By Product Type, 2023-2033 8.3.7.4. Market Size and Forecast, By End User, 2023-2033 8.3.8. UK 8.3.8.1. Introduction 8.3.8.2. Driving Factors, Opportunity Analyzed, and Key Trends 8.3.8.3. Market Size and Forecast, By Product Type, 2023-2033 8.3.8.4. Market Size and Forecast, By End User, 2023-2033 8.3.9. Italy 8.3.9.1. Introduction 8.3.9.2. Driving Factors, Opportunity Analyzed, and Key Trends 8.3.9.3. Market Size and Forecast, By Product Type, 2023-2033 8.3.9.4. Market Size and Forecast, By End User, 2023-2033 8.3.11. Rest Of Europe 8.3.11.1. Introduction 8.3.11.2. Driving Factors, Opportunity Analyzed, and Key Trends 8.3.11.3. Market Size and Forecast, By Product Type, 2023-2033 8.3.11.4. Market Size and Forecast, By End User, 2023-2033 8.4. Asia-Pacific 8.4.1. Introduction 8.4.2. Driving Factors, Opportunity Analyzed, and Key Trends 8.4.3. Market Size and Forecast, By Country, 2023-2033 8.4.4. Market Size and Forecast, By Product Type, 2023-2033 8.12.28. Market Size and Forecast, By End User, 2023-2033 8.4.6. China 8.4.6.1. Introduction 8.4.6.2. Driving Factors, Opportunity Analyzed, and Key Trends 8.4.6.3. Market Size and Forecast, By Product Type, 2023-2033 8.4.6.4. Market Size and Forecast, By End User, 2023-2033 8.4.7. India 8.4.7.1. Introduction 8.4.7.2. Driving Factors, Opportunity Analyzed, and Key Trends 8.4.7.3. Market Size and Forecast, By Product Type, 2023-2033 8.4.7.4. Market Size and Forecast, By End User, 2023-2033 8.4.8. Japan 8.4.8.1. Introduction 8.4.8.2. Driving Factors, Opportunity Analyzed, and Key Trends 8.4.8.3. Market Size and Forecast, By Product Type, 2023-2033 8.4.8.4. Market Size and Forecast, By End User, 2023-2033 8.4.9. South Korea 8.4.9.1. Introduction 8.4.9.2. Driving Factors, Opportunity Analyzed, and Key Trends 8.4.9.3. Market Size and Forecast, By Product Type, 2023-2033 8.4.9.4. Market Size and Forecast, By End User, 2023-2033 8.4.10. Rest Of Asia-Pacific 8.4.10.1. Introduction 8.4.10.2. Driving Factors, Opportunity Analyzed, and Key Trends 8.4.10.3. Market Size and Forecast, By Product Type, 2023-2033 8.4.10.4. Market Size and Forecast, By End User, 2023-2033 8.5. Rest Of The World (RoW) 8.5.1. Introduction 8.5.2. Driving Factors, Opportunity Analyzed, and Key Trends 8.5.3. Market Size and Forecast, By Product Type, 2023-2033 8.5.4. Market Size and Forecast, By End User, 2023-2033 Chapter 9. Company Landscape 9.1. Introduction 9.2. Vendor Share Analysis 9.3. Key Development Analysis 9.4. Competitor Dashboard Chapter 10. Company Profiles 10.1. ABB 10.1.1. Business Overview 10.1.2. Government & Defense Analysis 10.1.2.1. Government & Defense – Existing/Funding 10.1.3. Product Portfolio 10.1.4. Recent Development and Strategies Adopted 10.1.5. SWOT Analysis 10.2. Siemens 10.2.1. Business Overview 10.2.2. Government & Defense Analysis 10.2.2.1. Government & Defense – Existing/Funding 10.2.3. Product Portfolio 10.2.4. Recent Development and Strategies Adopted 10.2.5. SWOT Analysis 10.3. Honeywell 10.3.1. Business Overview 10.3.2. Government & Defense Analysis 10.3.2.1. Government & Defense – Existing/Funding 10.3.3. Product Portfolio 10.3.4. Recent Development and Strategies Adopted 10.3.5. SWOT Analysis 10.4. Yokogawa 10.4.1. Business Overview 10.4.2. Government & Defense Analysis 10.4.2.1. Government & Defense – Existing/Funding 10.4.3. Product Portfolio 10.4.4. Recent Development and Strategies Adopted 10.12.28. SWOT Analysis 10.5. Emerson 10.5.1. Business Overview 10.5.2. Government & Defense Analysis 10.5.2.1. Government & Defense – Existing/Funding 10.5.3. Product Portfolio 10.5.4. Recent Development and Strategies Adopted 10.5.5. SWOT Analysis 10.6. Schneider Electric 10.6.1. Business Overview 10.6.2. Government & Defense Analysis 10.6.2.1. Government & Defense – Existing/Funding 10.6.3. Product Portfolio 10.6.4. Recent Development and Strategies Adopted 10.6.5. SWOT Analysis 10.7. General Electric 10.7.1. Business Overview 10.7.2. Government & Defense Analysis 10.7.2.1. Government & Defense – Existing/Funding 10.7.3. Product Portfolio 10.7.4. Recent Development and Strategies Adopted 10.7.5. SWOT Analysis 10.8 Rockwell 10.8.1. Business Overview 10.8.2. Government & Defense Analysis 10.8.2.1. Government & Defense – Existing/Funding 10.8.3. Product Portfolio 10.8.4. Recent Development and Strategies Adopted 10.8.5. SWOT Analysis 10.9 Toshiba 10.9.1. Business Overview 10.9.2. Government & Defense Analysis 10.9.2.1. Government & Defense – Existing/Funding 10.9.3. Product Portfolio 10.9.4. Recent Development and Strategies Adopted 10.9.5. SWOT Analysis 10.10. METSO 10.10.1. Business Overview 10.10.2. Government & Defense Analysis 10.10.2.1. Government & Defense – Existing/Funding 10.10.3. Product Portfolio 10.10.4. Recent Development and Strategies Adopted 10.10.5. SWOT Analysis

Connect to Analyst

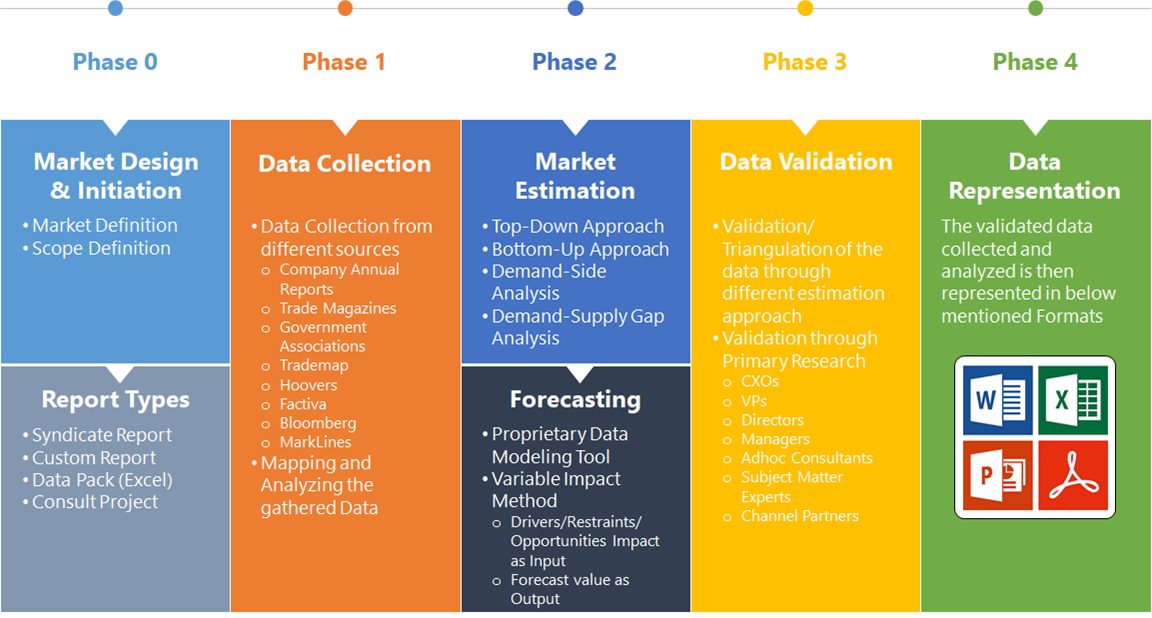

Research Methodology