Aviation Carbon Fiber Market Analysis and Global Forecast 2024-2034

$ 1,390.00 – $ 5,520.00Price range: $ 1,390.00 through $ 5,520.00

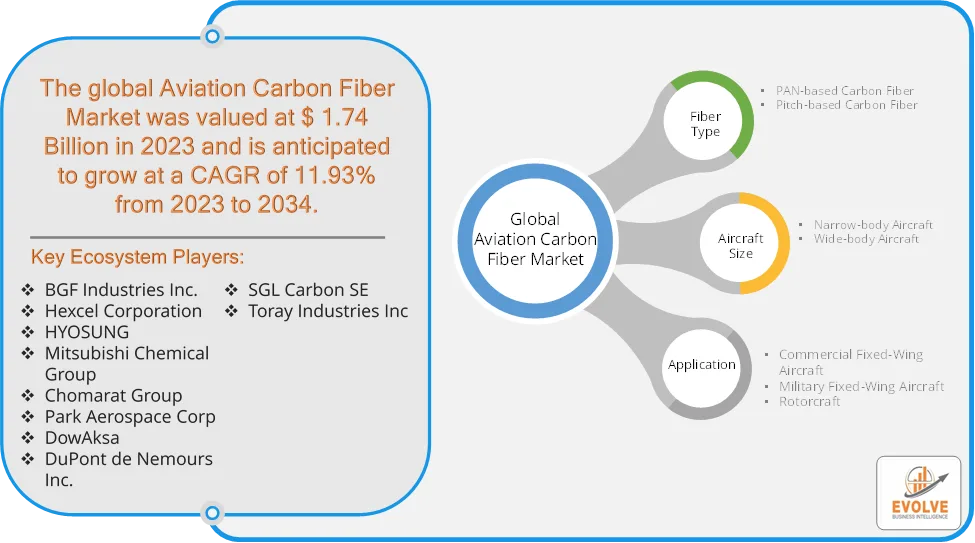

Aviation Carbon Fiber Market Research Report: Information By Fiber Type (PAN-based Carbon Fiber, Pitch-based Carbon Fiber), By Aircraft Size (Narrow-body Aircraft, Wide-body Aircraft), By Application (Commercial Fixed-Wing Aircraft, Military Fixed-Wing Aircraft, Rotorcraft), and by Region — Forecast till 2034

Page: 165

Aviation Carbon Fiber Market Overview

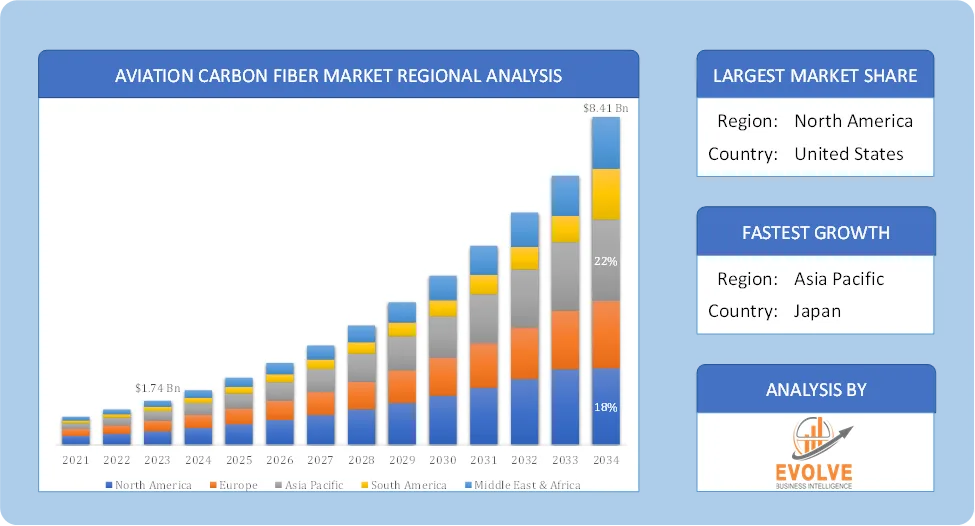

The Aviation Carbon Fiber Market size accounted for USD 1.74 Billion in 2023 and is estimated to account for 2.24 Billion in 2024. The Market is expected to reach USD 8.41 Billion by 2034 growing at a compound annual growth rate (CAGR) of 11.93% from 2024 to 2034. The Aviation Carbon Fiber Market is experiencing significant growth, driven by increasing demand for lightweight, high-strength materials in the aerospace industry. Carbon fiber composites offer superior strength-to-weight ratios, fuel efficiency, and resistance to extreme environmental conditions, making them a preferred choice for aircraft manufacturing.

The aviation carbon fiber market is poised for substantial growth, driven by the aerospace industry’s pursuit of lighter, more fuel-efficient, and sustainable aircraft. While challenges related to cost and maintenance exist, ongoing technological advancements and increasing environmental pressures are expected to further propel the adoption of carbon fiber composites in aviation.

Global Aviation Carbon Fiber Market Synopsis

Aviation Carbon Fiber Market Dynamics

Aviation Carbon Fiber Market Dynamics

The major factors that have impacted the growth of Aviation Carbon Fiber Market are as follows:

Drivers:

Ø Increasing Demand for Lightweight & Fuel-Efficient Aircraft

Carbon fiber composites significantly reduce aircraft weight, improving fuel efficiency and reducing carbon emissions. Airlines are increasingly adopting lightweight materials to comply with International Civil Aviation Organization (ICAO) and European Union Aviation Safety Agency (EASA) fuel efficiency standards. Lighter aircraft enable extended flight ranges and higher payload capacities, benefiting both commercial and military aviation. Growing global air travel demand is driving new aircraft production and the adoption of advanced composite materials.

Restraint:

- High Cost of Carbon Fiber Production and Complex Manufacturing

Carbon fiber is significantly more expensive than traditional materials like aluminum and steel, making it less accessible for some aircraft manufacturers. The complex manufacturing process, including polyacrylonitrile (PAN) precursor production and high-temperature carbonization, increases overall costs. The fabrication and integration of carbon fiber composites require specialized production techniques, such as automated fiber placement (AFP) and resin transfer molding (RTM) and Skilled labor and advanced machinery are necessary, making it difficult for smaller manufacturers to adopt carbon fiber on a large scale.

Opportunity:

⮚ Advancements in Carbon Fiber Recycling & Sustainability Initiatives

The industry is shifting towards recycled carbon fiber, reducing production costs and addressing environmental concerns. Companies are investing in closed-loop recycling systems to reuse carbon fiber waste, making it a viable alternative for sustainable aviation. Additive manufacturing (3D printing) using carbon fiber composites is gaining traction, enabling the production of complex aerospace components with reduced material waste and new manufacturing techniques, such as automated fiber placement (AFP) and out-of-autoclave (OoA) processing, are improving efficiency and reducing costs.

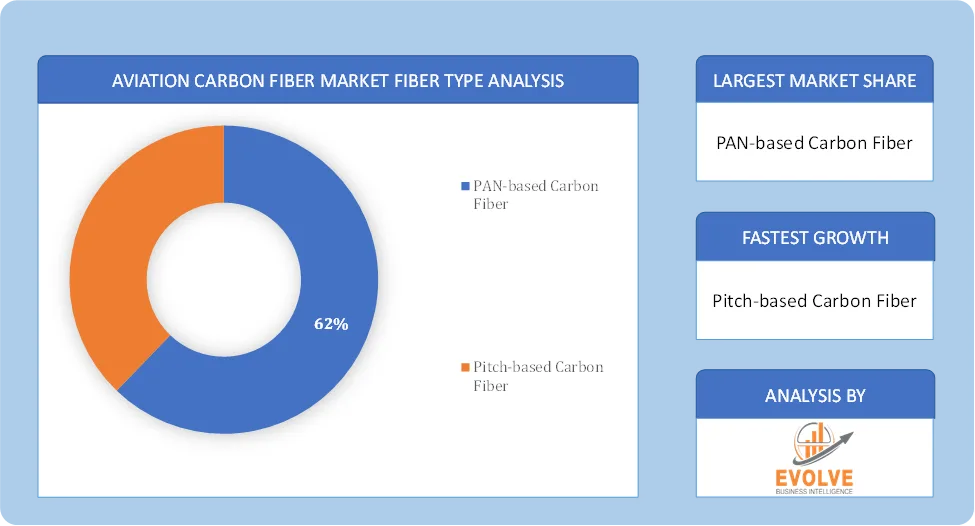

Aviation Carbon Fiber Market Segment Overview

Based on Fiber Type, the market is segmented based on PAN-based Carbon Fiber, Pitch-based Carbon Fiber. The PAN-based carbon fiber segment dominant the market. PAN-based carbon fiber is a type of carbon fiber that is produced from the polyacrylonitrile (PAN) precursor material. It is characterized by high strength, stiffness, and durability and therefore it is widely used in various applications. PAN-based carbon fiber is used in aircraft structures like wings, fuselages, and empennages.

By Aircraft Size

Based on Animal, the market segment has been divided into Narrow-body Aircraft, Wide-body Aircraft. The narrow-body aircraft segment dominant the market. This is due to the increasing demand for narrow-body aircraft from low-cost carriers and regional airlines.

By Application

Based on Application, the market segment has been divided into Commercial Fixed-Wing Aircraft, Military Fixed-Wing Aircraft, Rotorcraft. The commercial fixed-wing aircraft segment dominant the market. The constantly increasing frequency of air passengers and the requirement for airlines to decrease expenses prompt the use of carbon fiber in commercial aircraft. The increase in commercial air traffic has led to a rise in the contribution of the aviation sector to global emissions. Aviation causes greenhouse gas emissions that contribute to global warming.

Global Aviation Carbon Fiber Market Regional Analysis

Based on region, the global Aviation Carbon Fiber Market has been divided into North America, Europe, Asia-Pacific, the Middle East & Africa, and Latin America. North America is projected to dominate the use of the Aviation Carbon Fiber Market followed by the Asia-Pacific and Europe regions.

North America Aviation Carbon Fiber Market

North America holds a dominant position in the Aviation Carbon Fiber Market. Increased defense spending and the development of advanced military aircraft platforms heavily utilize carbon fiber due to its high strength-to-weight ratio and A large number of airlines and air traffic contribute to the demand for new, fuel-efficient aircraft. Increasing use of carbon fiber in both commercial and military fixed-wing aircraft, driven by the need for lightweight and high-performance materials and Continuous innovation in carbon fiber manufacturing and material development further support market growth.

Asia-Pacific Aviation Carbon Fiber Market

The Asia-Pacific region has indeed emerged as the fastest-growing market for the Aviation Carbon Fiber Market industry. Countries like China and Japan are investing in carbon fiber production and application development. Rapid adoption of carbon fiber in commercial aircraft, driven by the expanding fleet and the need for fuel efficiency and Increasing focus on indigenous production and technological advancements in carbon fiber manufacturing and Increasing air traffic, the rise of low-cost carriers, and the development of new airports are boosting aircraft demand.

Competitive Landscape

The global Aviation Carbon Fiber Market is highly competitive, with numerous players offering a wide range of software solutions. The competitive landscape is characterized by the presence of established companies, as well as emerging startups and niche players. To increase their market position and attract a wide consumer base, the businesses are employing various strategies, such as product launches, and strategic alliances.

Prominent Players:

- BGF Industries Inc.

- Hexcel Corporation

- HYOSUNG

- Mitsubishi Chemical Group

- Chomarat Group

- Park Aerospace Corp

- DowAksa

- DuPont de Nemours Inc.

- SGL Carbon SE

- Toray Industries Inc.

Scope of the Report

Global Aviation Carbon Fiber Market, by Fiber Type

- PAN-based Carbon Fiber

- Pitch-based Carbon Fiber

Global Aviation Carbon Fiber Market, by Aircraft Size

- Narrow-body Aircraft

- Wide-body Aircraft

Global Aviation Carbon Fiber Market, by Application

- Commercial Fixed-Wing Aircraft

- Military Fixed-Wing Aircraft

- Rotorcraft

Global Aviation Carbon Fiber Market, by Region

- North America

- US

- Canada

- Mexico

- Europe

- UK

- Germany

- France

- Italy

- Spain

- Benelux

- Nordic

- Rest of Europe

- Asia Pacific

- China

- Japan

- South Korea

- Indonesia

- Austalia

- Malaysia

- India

- Rest of Asia Pacific

- South America

- Brazil

- Argentina

- Rest of South America

- Middle East & Africa

- Saudi Arabia

- UAE

- Egypt

- South Africa

- Rest of Middle East & Africa

| Parameters | Indicators |

|---|---|

| Market Size | 2034: USD 8.41 Billion |

| CAGR (2024-2034) | 11.93% |

| Base year | 2022 |

| Forecast Period | 2024-2034 |

| Historical Data | 2021 (2017 to 2020 On Demand) |

| Report Coverage | Revenue Forecast, Competitive Landscape, Growth Factors, and Trends |

| Key Segmentations | Fiber Type, Aircraft Size, Application |

| Geographies Covered | North America, Europe, Asia-Pacific, South America, Middle East, Africa |

| Key Vendors | BGF Industries Inc., Hexcel Corporation, HYOSUNG, Mitsubishi Chemical Group, Chomarat Group, Park Aerospace Corp, DowAksa, DuPont de Nemours Inc., SGL Carbon SE and Toray Industries Inc. |

| Key Market Opportunities | · Advancements in Carbon Fiber Recycling & Sustainability Initiatives · Innovations in Carbon Fiber Manufacturing & 3D Printing |

| Key Market Drivers | · Increasing Demand for Lightweight & Fuel-Efficient Aircraft · Rising Air Passenger Traffic & Fleet Expansion |

REPORT CONTENT BRIEF:

- High-level analysis of the current and future Aviation Carbon Fiber Market trends and opportunities

- Detailed analysis of current market drivers, restraining factors, and opportunities in the future

- Aviation Carbon Fiber Market historical market size for the year 2021, and forecast from 2023 to 2033

- Aviation Carbon Fiber Market share analysis at each product level

- Competitor analysis with detailed insight into its product segment, Government & Defense strength, and strategies adopted.

- Identifies key strategies adopted including product launches and developments, mergers and acquisitions, joint ventures, collaborations, and partnerships as well as funding taken and investment done, among others.

- To identify and understand the various factors involved in the global Aviation Carbon Fiber Market affected by the pandemic

- To provide a detailed insight into the major companies operating in the market. The profiling will include the Government & Defense health of the company’s past 2-3 years with segmental and regional revenue breakup, product offering, recent developments, SWOT analysis, and key strategies.

Frequently Asked Questions (FAQ)

What is the study period of this market?

The study period of the global Aviation Carbon Fiber Market is 2021- 2033

What is the growth rate of the global Aviation Carbon Fiber Market?

The global Aviation Carbon Fiber Market is growing at a CAGR of 11.93% over the next 10 years

Which region has the highest growth rate in the market of Aviation Carbon Fiber Market?

Asia Pacific is expected to register the highest CAGR during 2024-2034

Which region has the largest share of the global Aviation Carbon Fiber Market?

North America holds the largest share in 2022

Who are the key players in the global Aviation Carbon Fiber Market?

BGF Industries Inc., Hexcel Corporation, HYOSUNG, Mitsubishi Chemical Group, Chomarat Group, Park Aerospace Corp, DowAksa, DuPont de Nemours Inc., SGL Carbon SE and Toray Industries Inc. are the major companies operating in the market.

Do you offer Post Sale Support?

Yes, we offer 16 hours of analyst support to solve the queries

Do you sell particular sections of a report?

Yes, we provide regional as well as country-level reports. Other than this we also provide a sectional report. Please get in contact with our sales representatives.

Press Release

Global Pharmaceutical Manufacturing Market to Reach $1.38 Trillion by 2035 with 7.35% CAGR, New Research Shows

The Global Mammography Market Is Estimated To Record a CAGR of Around 10.29% During The Forecast Period

Glue Stick Market to Reach USD 2.35 Billion by 2034

Podiatry Service Market to Reach USD 11.88 Billion by 2034

Microfluidics Technology Market to Reach USD 32.58 Billion by 2034

Ferric Chloride Market to Reach USD 10.65 Billion by 2034

Family Practice EMR Software Market to Reach USD 21.52 Billion by 2034

Electric Hairbrush Market to Reach USD 15.95 Billion by 2034

Daily Bamboo Products Market to Reach USD 143.52 Billion by 2034

Cross-border E-commerce Logistics Market to Reach USD 112.65 Billion by 2034

Table of Content

CHAPTER 1. Executive Summary

CHAPTER 2. Scope of the Study

2.1. Market Definition

2.2. Market Scope & Segmentation

2.2.1. Objective of Report

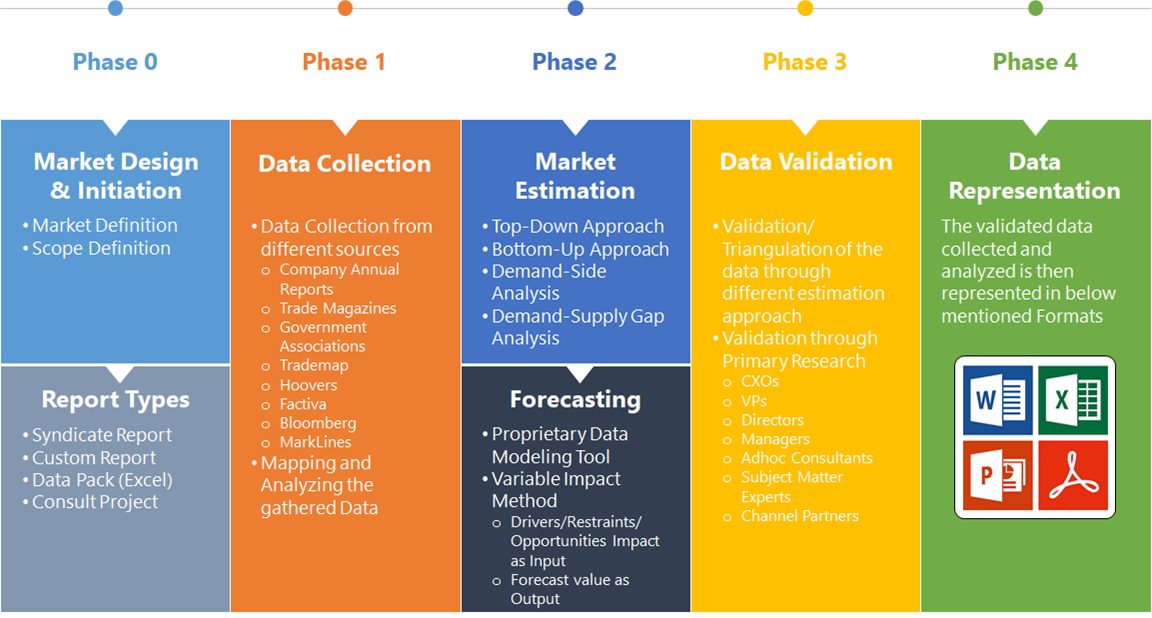

CHAPTER 3. Evolve BI Methodology

3.1. Data Collection & Validation Approach

3.2. Market Size Estimation and Forecast

CHAPTER 4. Exclusive Analysis

4.1. Market Opportunity Score

4.1.1. Fiber Type Segement – Market Opportunity Score

4.1.2. Aircraft Size Segment – Market Opportunity Score

4.1.3. Application Segment – Market Opportunity Score

4.2. Key Market Influencing Indicators

CHAPTER 5. Market Insights and Trends

5.1. Value Chain Analysis

5.1.1. Raw Material

5.1.2. Manufacturing Process

5.1.3. Distribution Channel

5.1.4. End User

5.2. Porter’s Five Forces Analysis

5.2.1. Bargaining Power of Buyers

5.2.2. Bargaining Power of Suppliers

5.2.3. Threat of New Entrant

5.2.4. Threat of Substitute

5.2.5. Industry Rivalry

5.3. COVID-19 Impact and Post COVID Scenario on Aviation Carbon Fiber Market

5.3.1. Impact of COVID-19

5.3.2. Government Support and Industry Revival Policies

5.3.3. Measures Taken by Companies to Mitigate Negative Impact

5.3.4. Post COVID Trend

CHAPTER 6. Market Dynamics

6.1. Introduction

6.2. Drivers

6.2.1. Driver 1

6.2.2. Driver 2

6.2.3. Driver 3

6.3. Restraints

6.3.1. Restraint 1

6.3.2. Restraint 2

6.4. Opportunity

6.4.1. Opportunity 1

CHAPTER 7. Aviation Carbon Fiber Market, By Fiber Type

7.1. Introduction

7.1.1. PAN-based Carbon Fiber

7.1.2 Pitch-based Carbon Fiber

CHAPTER 8 Aviation Carbon Fiber Market, By Aircraft Size

8.1. Introduction

8.1.1. Narrow-body Aircraft

8.1.2. Wide-body Aircraft

CHAPTER 9. Aviation Carbon Fiber Market, By Application

9.1. Introduction

9.1.1. Commercial Fixed-Wing Aircraft

9.1.2. Military Fixed-Wing Aircraft

9.1.3. Rotorcraft

CHAPTER 10. Aviation Carbon Fiber Market, By Region

10.1. Introduction

10.2. NORTH AMERICA

10.2.1. North America: Market Size and Forecast, By Country, 2024 – 2034($ Million)

10.2.2. North America: Market Size and Forecast, By Fiber Type, 2024 – 2034($ Million)

10.2.3. North America: Market Size and Forecast, By Aircraft Size, 2024 – 2034($ Million)

10.2.4. North America: Market Size and Forecast, By Application, 2024 – 2034($ Million)

10.2.5. US

10.2.5.1. US: Market Size and Forecast, By Fiber Type, 2024 – 2034($ Million)

10.2.5.2. US: Market Size and Forecast, By Aircraft Size, 2024 – 2034($ Million)

10.2.5.3. US: Market Size and Forecast, By Application, 2024 – 2034($ Million)

10.2.6. CANADA

10.2.6.1. Canada: Market Size and Forecast, By Fiber Type, 2024 – 2034($ Million)

10.2.6.2. Canada: Market Size and Forecast, By Aircraft Size, 2024 – 2034($ Million)

10.2.6.3. Canada: Market Size and Forecast, By Application, 2024 – 2034($ Million)

10.2.7. MEXICO

10.2.7.1. Mexico: Market Size and Forecast, By Fiber Type, 2024 – 2034($ Million)

10.2.7.2. Mexico: Market Size and Forecast, By Aircraft Size, 2024 – 2034($ Million)

10.2.7.3. Mexico: Market Size and Forecast, By Application, 2024 – 2034($ Million)

10.3. Europe

10.3.1. Europe: Market Size and Forecast, By Country, 2024 – 2034($ Million)

10.3.2. Europe: Market Size and Forecast, By Fiber Type, 2024 – 2034($ Million)

10.3.3. Europe: Market Size and Forecast, By Aircraft Size, 2024 – 2034($ Million)

10.3.4. Europe: Market Size and Forecast, By Application, 2024 – 2034($ Million)

10.3.5. U.K.

10.3.5.1. U.K.: Market Size and Forecast, By Fiber Type, 2024 – 2034($ Million)

10.3.5.2. U.K.: Market Size and Forecast, By Aircraft Size, 2024 – 2034($ Million)

10.3.5.3. U.K.: Market Size and Forecast, By Application, 2024 – 2034($ Million)

10.3.6. GERMANY

10.3.6.1. Germany: Market Size and Forecast, By Fiber Type, 2024 – 2034($ Million)

10.3.6.2. Germany: Market Size and Forecast, By Aircraft Size, 2024 – 2034($ Million)

10.3.6.3. Germany: Market Size and Forecast, By Application, 2024 – 2034($ Million)

10.3.7. FRANCE

10.3.7.1. France: Market Size and Forecast, By Fiber Type, 2024 – 2034($ Million)

10.3.7.2. France: Market Size and Forecast, By Aircraft Size, 2024 – 2034($ Million)

10.3.7.3. France: Market Size and Forecast, By Application, 2024 – 2034($ Million)

10.3.8. ITALY

10.3.8.1. Italy: Market Size and Forecast, By Fiber Type, 2024 – 2034($ Million)

10.3.8.2. Italy: Market Size and Forecast, By Aircraft Size, 2024 – 2034($ Million)

10.3.8.3. Italy: Market Size and Forecast, By Application, 2024 – 2034($ Million)

10.3.9. SPAIN

10.3.9.1. Spain: Market Size and Forecast, By Fiber Type, 2024 – 2034($ Million)

10.3.9.2. Spain: Market Size and Forecast, By Aircraft Size, 2024 – 2034($ Million)

10.3.9.3. Spain: Market Size and Forecast, By Application, 2024 – 2034($ Million)

10.3.10. BENELUX

10.3.10.1. BeNeLux: Market Size and Forecast, By Fiber Type, 2024 – 2034($ Million)

10.3.10.2. BeNeLux: Market Size and Forecast, By Aircraft Size, 2024 – 2034($ Million)

10.3.10.3. BeNeLux: Market Size and Forecast, By Application, 2024 – 2034($ Million)

10.3.11. RUSSIA

10.3.11.1. Russia: Market Size and Forecast, By Fiber Type, 2024 – 2034($ Million)

10.3.11.2. Russia: Market Size and Forecast, By Aircraft Size, 2024 – 2034($ Million)

10.3.11.3. Russia: Market Size and Forecast, By Application, 2024 – 2034($ Million)

10.3.12. REST OF EUROPE

10.3.12.1. Rest of Europe: Market Size and Forecast, By Fiber Type, 2024 – 2034($ Million)

10.3.12.2. Rest of Europe: Market Size and Forecast, By Aircraft Size, 2024 – 2034($ Million)

10.3.12.3. Rest of Europe: Market Size and Forecast, By Application, 2024 – 2034($ Million)

10.4. Asia Pacific

10.4.1. Asia Pacific: Market Size and Forecast, By Country, 2024 – 2034($ Million)

10.4.2. Asia Pacific: Market Size and Forecast, By Fiber Type, 2024 – 2034($ Million)

10.4.3. Asia Pacific: Market Size and Forecast, By Aircraft Size, 2024 – 2034($ Million)

10.4.4. Asia Pacific: Market Size and Forecast, By Application, 2024 – 2034($ Million)

10.4.5. CHINA

10.4.5.1. China: Market Size and Forecast, By Fiber Type, 2024 – 2034($ Million)

10.4.5.2. China: Market Size and Forecast, By Aircraft Size, 2024 – 2034($ Million)

10.4.5.3. China: Market Size and Forecast, By Application, 2024 – 2034($ Million)

10.4.6. JAPAN

10.4.6.1. Japan: Market Size and Forecast, By Fiber Type, 2024 – 2034($ Million)

10.4.6.2. Japan: Market Size and Forecast, By Aircraft Size, 2024 – 2034($ Million)

10.4.6.3. Japan: Market Size and Forecast, By Application, 2024 – 2034($ Million)

10.4.7. INDIA

10.4.7.1. India: Market Size and Forecast, By Fiber Type, 2024 – 2034($ Million)

10.4.7.2. India: Market Size and Forecast, By Aircraft Size, 2024 – 2034($ Million)

10.4.7.3. India: Market Size and Forecast, By Application, 2024 – 2034($ Million)

10.4.8. SOUTH KOREA

10.4.8.1. South Korea: Market Size and Forecast, By Fiber Type, 2024 – 2034($ Million)

10.4.8.2. South Korea: Market Size and Forecast, By Aircraft Size, 2024 – 2034($ Million)

10.4.8.3. South Korea: Market Size and Forecast, By Application, 2024 – 2034($ Million)

10.4.9. THAILAND

10.4.9.1. Thailand: Market Size and Forecast, By Fiber Type, 2024 – 2034($ Million)

10.4.9.2. Thailand: Market Size and Forecast, By Aircraft Size, 2024 – 2034($ Million)

10.4.9.3. Thailand: Market Size and Forecast, By Application, 2024 – 2034($ Million)

10.4.10. INDONESIA

10.4.10.1. Indonesia: Market Size and Forecast, By Fiber Type, 2024 – 2034($ Million)

10.4.10.2. Indonesia: Market Size and Forecast, By Aircraft Size, 2024 – 2034($ Million)

10.4.10.3. Indonesia: Market Size and Forecast, By Application, 2024 – 2034($ Million)

10.4.11. MALAYSIA

10.4.11.1. Malaysia: Market Size and Forecast, By Fiber Type, 2024 – 2034($ Million)

10.4.11.2. Malaysia: Market Size and Forecast, By Aircraft Size, 2024 – 2034($ Million)

10.4.11.3. Malaysia: Market Size and Forecast, By Application, 2024 – 2034($ Million)

10.4.12. AUSTRALIA

10.4.12.1. Australia: Market Size and Forecast, By Fiber Type, 2024 – 2034($ Million)

10.4.12.2. Australia: Market Size and Forecast, By Aircraft Size, 2024 – 2034($ Million)

10.4.12.3. Australia: Market Size and Forecast, By Application, 2024 – 2034($ Million)

10.4.13. REST FO ASIA PACIFIC

10.4.13.1. Rest fo Asia Pacific: Market Size and Forecast, By Fiber Type, 2024 – 2034($ Million)

10.4.13.2. Rest fo Asia Pacific: Market Size and Forecast, By Aircraft Size, 2024 – 2034($ Million)

10.4.13.3. Rest fo Asia Pacific: Market Size and Forecast, By Application, 2024 – 2034($ Million)

10.5. South America

10.5.1. South America: Market Size and Forecast, By Country, 2024 – 2034($ Million)

10.5.2. South America: Market Size and Forecast, By Fiber Type, 2024 – 2034($ Million)

10.5.3. South America: Market Size and Forecast, By System, 2024 – 2034($ Million)

10.5.4. South America: Market Size and Forecast, By Application, 2024 – 2034($ Million)

10.5.5. BRAZIL

10.5.5.1. Brazil: Market Size and Forecast, By Fiber Type, 2024 – 2034($ Million)

10.5.5.2. Brazil: Market Size and Forecast, By Aircraft Size, 2024 – 2034($ Million)

10.5.5.3. Brazil: Market Size and Forecast, By Application, 2024 – 2034($ Million)

10.5.6. ARGENTINA

10.5.6.1. Argentina: Market Size and Forecast, By Fiber Type, 2024 – 2034($ Million)

10.5.6.2. Argentina: Market Size and Forecast, By Aircraft Size, 2024 – 2034($ Million)

10.5.6.3. Argentina: Market Size and Forecast, By Application, 2024 – 2034($ Million)

10.5.7. REST OF SOUTH AMERICA

10.5.7.1. Rest of South America: Market Size and Forecast, By Fiber Type, 2024 – 2034($ Million)

10.5.7.2. Rest of South America: Market Size and Forecast, By Aircraft Size, 2024 – 2034($ Million)

10.5.7.3. Rest of South America: Market Size and Forecast, By Application, 2024 – 2034($ Million)

10.6. Middle East & Africa

10.6.1. Middle East & Africa: Market Size and Forecast, By Country, 2024 – 2034($ Million)

10.6.2. Middle East & Africa: Market Size and Forecast, By Fiber Type, 2024 – 2034($ Million)

10.6.3. Middle East & Africa: Market Size and Forecast, By Aircraft Size, 2024 – 2034($ Million)

10.6.4. Middle East & Africa: Market Size and Forecast, By Application, 2024 – 2034($ Million)

10.6.5. SAUDI ARABIA

10.6.5.1. Saudi Arabia: Market Size and Forecast, By Fiber Type, 2024 – 2034($ Million)

10.6.5.2. Saudi Arabia: Market Size and Forecast, By Aircraft Size, 2024 – 2034($ Million)

10.6.5.3. Saudi Arabia: Market Size and Forecast, By Application, 2024 – 2034($ Million)

10.6.6. UAE

10.6.6.1. UAE: Market Size and Forecast, By Fiber Type, 2024 – 2034($ Million)

10.6.6.2. UAE: Market Size and Forecast, By Aircraft Size, 2024 – 2034($ Million)

10.6.6.3. UAE: Market Size and Forecast, By Application, 2024 – 2034($ Million)

10.6.7. EGYPT

10.6.7.1. Egypt: Market Size and Forecast, By Fiber Type, 2024 – 2034($ Million)

10.6.7.2. Egypt: Market Size and Forecast, By Aircraft Size, 2024 – 2034($ Million)

10.6.7.3. Egypt: Market Size and Forecast, By Application, 2024 – 2034($ Million)

10.6.8. SOUTH AFRICA

10.6.8.1. South Africa: Market Size and Forecast, By Fiber Type, 2024 – 2034($ Million)

10.6.8.2. South Africa: Market Size and Forecast, By Aircraft Size, 2024 – 2034($ Million)

10.6.8.3. South Africa: Market Size and Forecast, By Application, 2024 – 2034($ Million)

10.6.9. REST OF MIDDLE EAST & AFRICA

10.6.9.1. Rest of Middle East & Africa: Market Size and Forecast, By Fiber Type, 2024 – 2034($ Million)

10.6.9.2. Rest of Middle East & Africa: Market Size and Forecast, By Aircraft Size, 2024 – 2034($ Million)

10.6.9.3.Rest of Middle East & Africa: Market Size and Forecast, By Application, 2024 – 2034($ Million)

CHAPTER 12. Competitive Landscape

12.1. Competitior Benchmarking 2023-

12.2. Market Share Analysis

12.3. Key Developments Analysis By Top 5 Companies

12.4. Market Share Acquisition Strategies: Analysis of Key Approaches Employed by Top Players

CHAPTER 13. Company Profiles

13.1. BGF Industries Inc.

13.1.1. Hanon Systems

13.1.2. Financial Analysis

13.1.2.1. Business Segment Revenue, 2020, 2021, 2022, $ Million

13.1.2.2. Geographic Revenue Mix, 2022 (% Share)

13.1.3. Product Portfolio

13.1.4. Recent Development and Strategies Adopted

13.1.5. SWOT Analysis

13.2. Hexcel Corporation

13.3. HYOSUNG

13.4. Mitsubishi Chemical Group

13.5. Chomarat Group

13.6. Park Aerospace Corp

13.7. DowAksa

13.8. DuPont de Nemours Inc.

13.9 SGL Carbon SE

13.10 Toray Industries Inc.

Connect to Analyst

Research Methodology