Aerospace Additive Manufacturing Market Analysis and Global Forecast 2021-2034

$ 1,390.00 – $ 5,520.00Price range: $ 1,390.00 through $ 5,520.00

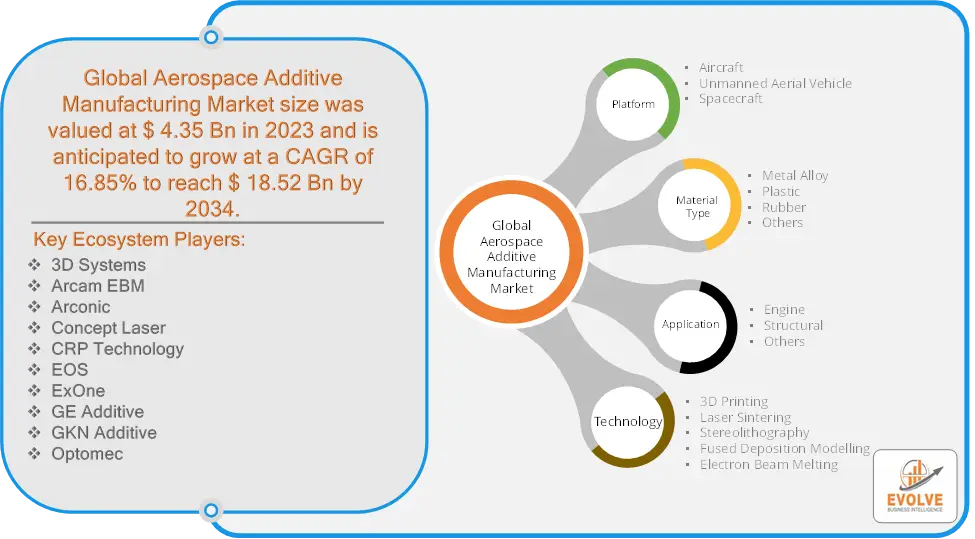

Aerospace Additive Manufacturing Market Research Report: Information By Platform (Aircraft, Unmanned Aerial Vehicle, Spacecraft), By Material Type (Metal Alloy, Plastic, Rubber, Others), By Application (Engine, Structural, Others), By Technology (3D Printing, Laser Sintering, Stereolithography, Fused Deposition Modelling, Electron Beam Melting), and by Region — Forecast till 2033

Page: 122

Aerospace Additive Manufacturing Market Overview

The Aerospace Additive Manufacturing Market Size is expected to reach USD 18.52 Billion by 2034. The Aerospace Additive Manufacturing Market industry size accounted for USD 4.35 Billion in 2023 and is expected to expand at a compound annual growth rate (CAGR) of 16.85% from 2021 to 2034. The Aerospace Additive Manufacturing Market refers to the industry segment focused on the use of additive manufacturing (AM) technologies, also known as 3D printing, within the aerospace sector. This market includes the development, production, and utilization of AM technologies to create aerospace components and systems.

The Aerospace Additive Manufacturing Market is growing as the aerospace industry increasingly adopts AM technologies for their benefits in enhancing performance, reducing weight, and improving overall efficiency.

Global Aerospace Additive Manufacturing Market Synopsis

Aerospace Additive Manufacturing Market Dynamics

Aerospace Additive Manufacturing Market Dynamics

The major factors that have impacted the growth of Aerospace Additive Manufacturing Market are as follows:

Drivers:

Ø Weight Reduction and Cost Efficiency

Additive manufacturing enables the production of lightweight and complex components, which is crucial for improving fuel efficiency and overall performance in aerospace applications. AM can reduce manufacturing costs by minimizing material waste and the need for extensive tooling. This is particularly beneficial for producing complex and custom parts. Continuous advancements in AM materials, such as high-performance alloys and composites, enhance the suitability of additive manufacturing for aerospace applications. AM is increasingly used for repair and maintenance of aerospace components, allowing for on-site or on-demand production of replacement parts, which can extend the lifespan of existing equipment.

Restraint:

- Perception of High Initial Costs and Material Limitations

The capital investment required for advanced additive manufacturing equipment and materials can be significant, which may be a barrier for some companies, especially smaller firms or startups. While there are advancements in AM materials, the range of materials that can be used in aerospace applications is still limited compared to traditional manufacturing methods. High-performance materials that meet aerospace standards are often costly and not as widely available.

Opportunity:

⮚ Advanced Materials Development

There is a significant opportunity to develop new materials specifically designed for aerospace applications, such as high-temperature alloys, advanced composites, and lightweight polymers. These materials can enhance performance and expand the range of parts that can be manufactured using AM. AM has the potential to support sustainability goals by reducing material waste, enabling more efficient use of resources, and supporting the development of eco-friendly materials. This aligns with the aerospace industry’s increasing focus on reducing its environmental impact. As the space industry expands, there are growing opportunities for AM in the production of components for spacecraft, satellites, and other space-related technologies. AM can offer cost-effective and flexible Material Types for the emerging space market.

Aerospace Additive Manufacturing Market Segment Overview

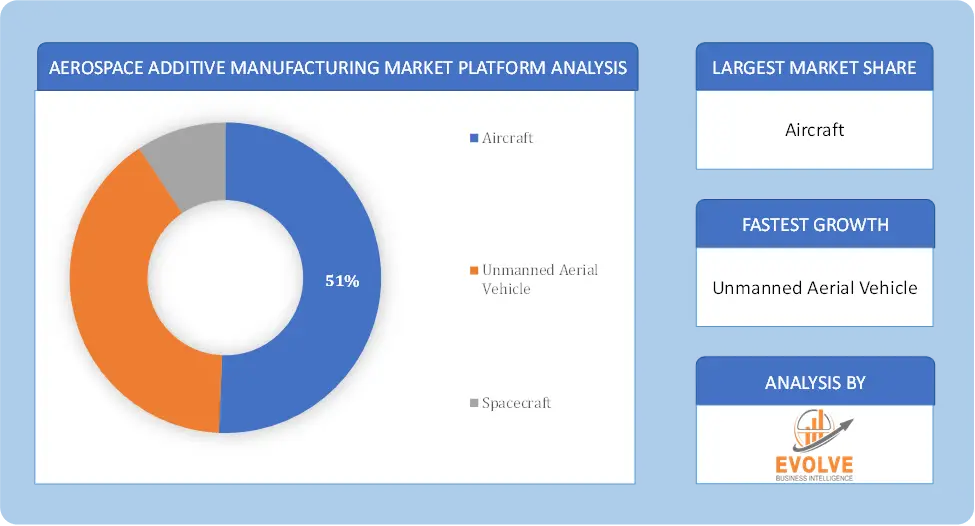

By Platform

Based on Platform, the market is segmented based on Aircraft, Unmanned Aerial Vehicle and Spacecraft. The aircraft segment dominant the market. Aircraft lead the market due to their need for lightweight, high-strength components that enhance fuel efficiency and performance. Unlike traditional methods, additive manufacturing enables the creation of complex geometries and customized parts, significantly reducing weight and material waste. This technology is particularly advantageous in producing critical components like engine parts, structural elements, and interior fixtures, where precision and performance are paramount.

Based on Platform, the market is segmented based on Aircraft, Unmanned Aerial Vehicle and Spacecraft. The aircraft segment dominant the market. Aircraft lead the market due to their need for lightweight, high-strength components that enhance fuel efficiency and performance. Unlike traditional methods, additive manufacturing enables the creation of complex geometries and customized parts, significantly reducing weight and material waste. This technology is particularly advantageous in producing critical components like engine parts, structural elements, and interior fixtures, where precision and performance are paramount.

By Material Type

Based on Material Type, the market segment has been divided into Metal Alloy, Plastic, Rubber and Others. The metal alloy segment dominant the market. Metal alloys are used due to their exceptional strength-to-weight ratio, durability, and heat resistance. Alloys such as titanium and aluminum are ideal for producing high-performance components like engine parts and structural elements. These materials enable the creation of intricate geometries and lightweight designs that enhance aircraft performance and fuel efficiency.

By Application

Based on Application, the market segment has been divided into Engine, Structural and Others. The engine segment dominant the market. Engines are gaining prominence in the market due to the critical need for high-performance, durable, and lightweight components that can withstand extreme temperatures and stresses. Moreover, additive manufacturing allows for the creation of complex geometries and integrated parts, which improve engine efficiency and reduce weight. The ability to produce intricate cooling channels and optimized structures enhances engine performance and fuel efficiency.

By Technology

Based on Technology, the market segment has been divided into 3D Printing, Laser Sintering, Stereolithography, Fused Deposition Modelling and Electron Beam Melting. The 3D printing possesses the ability to product complex, lightweight structures that improve fuel efficiency and performance, thereby marking its dominance in the market. Furthermore, it allows for rapid prototyping, which enables faster design iterations and reduced development times. The technology also supports the production of customized, high-strength components with minimal waste, which is critical for aerospace applications.

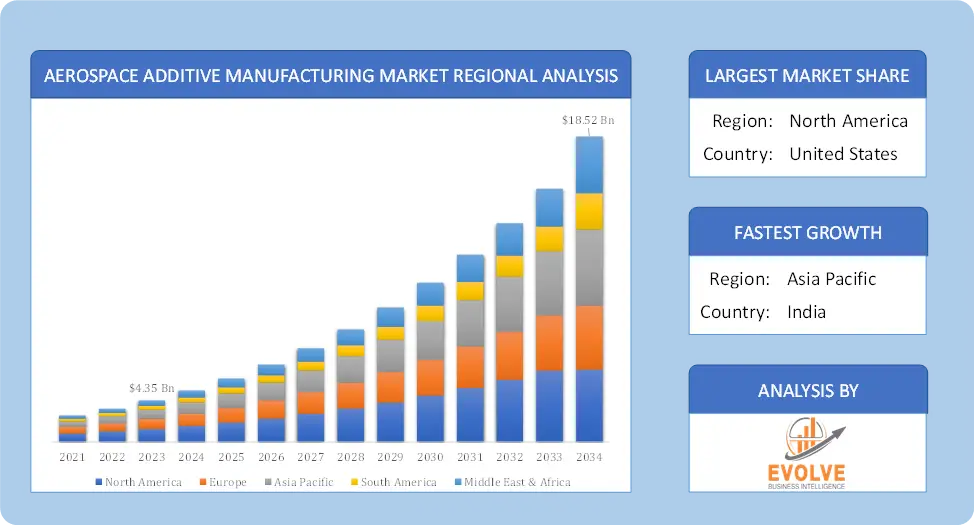

Global Aerospace Additive Manufacturing Market Regional Analysis

Based on region, the global Aerospace Additive Manufacturing Market has been divided into North America, Europe, Asia-Pacific, the Middle East & Africa, and Latin America. North America is projected to dominate the use of the Aerospace Additive Manufacturing Market followed by the Asia-Pacific and Europe regions.

Aerospace Additive Manufacturing North America Market

Aerospace Additive Manufacturing North America Market

North America holds a dominant position in the Aerospace Additive Manufacturing Market. North America, particularly the United States, is a leading market for aerospace additive manufacturing. The presence of major aerospace companies, a robust technological infrastructure, and significant R&D investments drive market growth and high levels of innovation and advancements in AM technology are driven by both private companies and government-funded research initiatives.

Aerospace Additive Manufacturing Asia-Pacific Market

The Asia-Pacific region has indeed emerged as the fastest-growing market for the Aerospace Additive Manufacturing Market industry. The Asia-Pacific region is an emerging market with rapid growth potential, driven by increasing aerospace manufacturing activities in countries like China, Japan, and India and the growing aerospace industry in Asia-Pacific is contributing to increased demand for AM technologies for both commercial and military applications.

Competitive Landscape

The global Aerospace Additive Manufacturing Market is highly competitive, with numerous players offering a wide range of software Material Types. The competitive landscape is characterized by the presence of established companies, as well as emerging startups and niche players. To increase their market position and attract a wide consumer base, the businesses are employing various strategies, such as product launches, and strategic alliances.

Prominent Players:

- 3D Systems

- Arcam EBM

- Arconic

- Concept Laser

- CRP Technology

- EOS

- ExOne

- GE Additive

- GKN Additive

- Optomec

Key Development

In February 2021, The United States Department of Defence has secured a USD 1.6 million deal with ExOne for container 3D printing plants. According to the deal, the company will build a 3D printing pod in a normal shipping container up to 40 feet long.

Scope of the Report

Global Aerospace Additive Manufacturing Market, by Platform

- Aircraft

- Unmanned Aerial Vehicle

- Spacecraft

Global Aerospace Additive Manufacturing Market, by Material Type

- Metal Alloy

- Plastic

- Rubber

- Others

Global Aerospace Additive Manufacturing Market, by Application

- Engine

- Structural

- Others

Global Aerospace Additive Manufacturing Market, by Technology

- 3D Printing

- Laser Sintering

- Stereolithography

- Fused Deposition Modelling

- Electron Beam Melting

Global Aerospace Additive Manufacturing Market, by Region

- North America

- US

- Canada

- Mexico

- Europe

- UK

- Germany

- France

- Italy

- Spain

- Benelux

- Nordic

- Rest of Europe

- Asia Pacific

- China

- Japan

- South Korea

- Indonesia

- Austalia

- Malaysia

- India

- Rest of Asia Pacific

- South America

- Brazil

- Argentina

- Rest of South America

- Middle East & Africa

- Saudi Arabia

- UAE

- Egypt

- South Africa

- Rest of Middle East & Africa

| Parameters | Indicators |

|---|---|

| Market Size | 2033: $18.52 Billion |

| CAGR | 16.85% CAGR (2023-2033) |

| Base year | 2022 |

| Forecast Period | 2023-2033 |

| Historical Data | 2021 |

| Report Coverage | Revenue Forecast, Competitive Landscape, Growth Factors, and Trends |

| Key Segmentations | Platform, Material Type, Technology, Application |

| Geographies Covered | North America, Europe, Asia-Pacific, Latin America, Middle East, Africa |

| Key Vendors | 3D Systems, Arcam EBM, Arconic, Concept Laser, CRP Technology, EOS, ExOne, GE Additive, GKN Additive and Optomec |

| Key Market Opportunities | • Advanced Materials Development • Growth in Space Exploration |

| Key Market Drivers | • Weight Reduction and Cost Efficiency • Material Advancements |

REPORT CONTENT BRIEF:

- High-level analysis of the current and future Aerospace Additive Manufacturing Market trends and opportunities

- Detailed analysis of current market drivers, restraining factors, and opportunities in the future

- Aerospace Additive Manufacturing Market historical market size for the year 2021, and forecast from 2023 to 2033

- Aerospace Additive Manufacturing Market share analysis at each product level

- Competitor analysis with detailed insight into its product segment, Government & Defense strength, and strategies adopted.

- Identifies key strategies adopted including product launches and developments, mergers and acquisitions, joint ventures, collaborations, and partnerships as well as funding taken and investment done, among others.

- To identify and understand the various factors involved in the global Aerospace Additive Manufacturing Market affected by the pandemic

- To provide a detailed insight into the major companies operating in the market. The profiling will include the Government & Defense health of the company’s past 2-3 years with segmental and regional revenue breakup, product offering, recent developments, SWOT analysis, and key strategies.

Press Release

Global Pharmaceutical Manufacturing Market to Reach $1.38 Trillion by 2035 with 7.35% CAGR, New Research Shows

The Global Mammography Market Is Estimated To Record a CAGR of Around 10.29% During The Forecast Period

Glue Stick Market to Reach USD 2.35 Billion by 2034

Podiatry Service Market to Reach USD 11.88 Billion by 2034

Microfluidics Technology Market to Reach USD 32.58 Billion by 2034

Ferric Chloride Market to Reach USD 10.65 Billion by 2034

Family Practice EMR Software Market to Reach USD 21.52 Billion by 2034

Electric Hairbrush Market to Reach USD 15.95 Billion by 2034

Daily Bamboo Products Market to Reach USD 143.52 Billion by 2034

Cross-border E-commerce Logistics Market to Reach USD 112.65 Billion by 2034

Frequently Asked Questions (FAQ)

What is the study period of this market?

The study period of the global Aerospace Additive Manufacturing Market is 2021- 2033

What is the growth rate of the global Aerospace Additive Manufacturing Market?

The global Aerospace Additive Manufacturing Market is growing at a CAGR of 16.85% over the next 10 years

Which region has the highest growth rate in the market of Aerospace Additive Manufacturing Market?

Asia Pacific is expected to register the highest CAGR during 2023-2033

Which region has the largest share of the global Aerospace Additive Manufacturing Market?

North America holds the largest share in 2022

Who are the key players in the global Aerospace Additive Manufacturing Market?

3D Systems, Arcam EBM, Arconic, Concept Laser, CRP Technology, EOS, ExOne, GE Additive, GKN Additive and Optomec are the major companies operating in the market.

Do you offer Post Sale Support?

Yes, we offer 16 hours of analyst support to solve the queries

Do you sell particular sections of a report?

Yes, we provide regional as well as country-level reports. Other than this we also provide a sectional report. Please get in contact with our sales representatives

Table of Content

Chapter 1. Executive Summary Chapter 2. Scope Of The Study 2.1. Market Definition 2.2. Scope Of The Study 2.2.1. Objectives of Report Chapter 3. Evolve BI Methodology Chapter 4. Market Insights and Trends 4.1. Supply/ Value Chain Analysis 4.2. Porter’s Five Forces Analysis 4.2.1. Threat Of New Entrants 4.2.2. Bargaining Power Of Buyers 4.2.3. Bargaining Power Of Suppliers 4.2.4. Threat Of Substitutes 4.2.5. Industry Rivalry 4.3. Impact of COVID-19 on Aerospace Additive Manufacturing Market 4.3.1. Impact on Market Size 4.3.2. Technologyr Trend, Preferences and Budget Impact 4.3.3. Regulatory Framework/Government Policies 4.3.4. Key Players Strategy to Tackle Negative Impact 4.3.5. Opportunity Window Chapter 5. Market Dynamics 5.1. Introduction 5.2. DRO Analysis 5.2.1. Drivers 5.2.2. Restraints 5.2.3. Opportunities Chapter 6. Global Aerospace Additive Manufacturing Market, By Platform 6.1. Introduction 6.2. Aircraft 6.3. Unmanned Aerial Vehicle 6.4. Spacecraft Chapter 7. Global Aerospace Additive Manufacturing Market, By Material Type 7.1. Introduction 7.2. Metal Alloy 7.3. Plastic 7.4. Rubber 7.5. Others Chapter 8. Global Aerospace Additive Manufacturing Market, By Application 8.1. Introduction 8.2. Engine 8.3. Structural 8.4. Others Chapter 9. Global Aerospace Additive Manufacturing Market, By Technology 9.1. Introduction 9.2. 3D Printing 9.3. Laser Sintering 9.4. Stereolithography 9.5. Fused Deposition Modelling 9.6. Electron Beam Melting Chapter 10. Global Aerospace Additive Manufacturing Market, By Region 10.1. Introduction 10.2. North America 10.2.1. Introduction 10.2.2. Driving Factors, Opportunity Analyzed and Key Trends 10.2.3. Market Size and Forecast, By Country, 2020 - 2028 10.2.4. Market Size and Forecast, By Platform, 2020 - 2028 10.2.5. Market Size and Forecast, By Material Type, 2020 - 2028 10.2.6. Market Size and Forecast, By Application, 2020 – 2028 10.2.7. Market Size and Forecast, By Technologyr, 2020 – 2028 10.2.8. US 10.2.8.1. Introduction 10.2.8.2. Driving Factors, Opportunity Analyzed and Key Trends 10.2.8.3. Market Size and Forecast, By Platform, 2020 - 2028 10.2.8.4. Market Size and Forecast, By Material Type, 2020 - 2028 10.2.8.5. Market Size and Forecast, By Application, 2020 – 2028 10.2.8.6. Market Size and Forecast, By Technologyr, 2020 - 2028 10.2.9. Canada 10.2.9.1. Introduction 10.2.9.2. Driving Factors, Opportunity Analyzed and Key Trends 10.2.9.3. Market Size and Forecast, By Platform, 2020 - 2028 10.2.9.4. Market Size and Forecast, By Material Type, 2020 - 2028 10.2.9.5. Market Size and Forecast, By Application, 2020 – 2028 10.2.9.6. Market Size and Forecast, By Technologyr, 2020 - 2028 10.3. Europe 10.3.1. Introduction 10.3.2. Driving Factors, Opportunity Analyzed and Key Trends 10.3.3. Market Size and Forecast, By Country, 2020 - 2028 10.3.4. Market Size and Forecast, By Platform, 2020 - 2028 10.3.5. Market Size and Forecast, By Material Type, 2020 - 2028 10.3.6. Market Size and Forecast, By Application, 2020 – 2028 10.3.7. Market Size and Forecast, By Technologyr, 2020 – 2028 10.3.8. Germany 10.3.8.1. Introduction 10.3.8.2. Driving Factors, Opportunity Analyzed and Key Trends 10.3.8.3. Market Size and Forecast, By Platform, 2020 - 2028 10.3.8.4. Market Size and Forecast, By Material Type, 2020 - 2028 10.3.8.5. Market Size and Forecast, By Application, 2020 – 2028 10.3.8.6. Market Size and Forecast, By Technologyr, 2020 - 2028 10.3.9. France 10.3.9.1. Introduction 10.3.9.2. Driving Factors, Opportunity Analyzed and Key Trends 10.3.9.3. Market Size and Forecast, By Platform, 2020 - 2028 10.3.9.4. Market Size and Forecast, By Material Type, 2020 - 2028 10.3.9.5. Market Size and Forecast, By Application, 2020 – 2028 10.3.9.6. Market Size and Forecast, By Technologyr, 2020 - 2028 10.3.10. UK 10.3.10.1. Introduction 10.3.10.2. Driving Factors, Opportunity Analyzed and Key Trends 10.3.10.3. Market Size and Forecast, By Platform, 2020 - 2028 10.3.10.4. Market Size and Forecast, By Material Type, 2020 - 2028 10.3.10.5. Market Size and Forecast, By Application, 2020 – 2028 10.3.10.6. Market Size and Forecast, By Technologyr, 2020 - 2028 10.3.11. Italy 10.3.11.1. Introduction 10.3.11.2. Driving Factors, Opportunity Analyzed and Key Trends 10.3.11.3. Market Size and Forecast, By Platform, 2020 - 2028 10.3.11.4. Market Size and Forecast, By Material Type, 2020 - 2028 10.3.11.5. Market Size and Forecast, By Application, 2020 – 2028 10.3.11.6. Market Size and Forecast, By Technologyr, 2020 - 2028 10.3.12. Rest Of Europe 10.3.12.1. Introduction 10.3.12.2. Driving Factors, Opportunity Analyzed and Key Trends 10.3.12.3. Market Size and Forecast, By Platform, 2020 - 2028 10.3.12.4. Market Size and Forecast, By Material Type, 2020 - 2028 10.3.12.5. Market Size and Forecast, By Application, 2020 – 2028 10.3.12.6. Market Size and Forecast, By Technologyr, 2020 - 2028 10.4. Asia-Pacific 10.4.1. Introduction 10.4.2. Driving Factors, Opportunity Analyzed and Key Trends 10.4.3. Market Size and Forecast, By Country, 2020 - 2028 10.4.4. Market Size and Forecast, By Platform, 2020 - 2028 10.4.5. Market Size and Forecast, By Material Type, 2020 - 2028 10.4.6. Market Size and Forecast, By Application, 2020 – 2028 10.4.7. Market Size and Forecast, By Technologyr, 2020 - 2028 10.4.8. China 10.4.8.1. Introduction 10.4.8.2. Driving Factors, Opportunity Analyzed and Key Trends 10.4.8.3. Market Size and Forecast, By Platform, 2020 - 2028 10.4.8.4. Market Size and Forecast, By Material Type, 2020 - 2028 10.4.8.5. Market Size and Forecast, By Application, 2020 – 2028 10.4.8.6. Market Size and Forecast, By Technologyr, 2020 - 2028 10.4.9. India 10.4.9.1. Introduction 10.4.9.2. Driving Factors, Opportunity Analyzed and Key Trends 10.4.9.3. Market Size and Forecast, By Platform, 2020 - 2028 10.4.9.4. Market Size and Forecast, By Material Type, 2020 - 2028 10.4.9.5. Market Size and Forecast, By Application, 2020 – 2028 10.4.9.6. Market Size and Forecast, By Technologyr, 2020 - 2028 10.4.10. Japan 10.4.10.1. Introduction 10.4.10.2. Driving Factors, Opportunity Analyzed and Key Trends 10.4.10.3. Market Size and Forecast, By Platform, 2020 - 2028 10.4.10.4. Market Size and Forecast, By Material Type, 2020 - 2028 10.4.10.5. Market Size and Forecast, By Application, 2020 – 2028 10.4.10.6. Market Size and Forecast, By Technologyr, 2020 - 2028 10.4.11. South Korea 10.4.11.1. Introduction 10.4.11.2. Driving Factors, Opportunity Analyzed and Key Trends 10.4.11.3. Market Size and Forecast, By Platform, 2020 - 2028 10.4.11.4. Market Size and Forecast, By Material Type, 2020 - 2028 10.4.11.5. Market Size and Forecast, By Application, 2020 – 2028 10.4.11.6. Market Size and Forecast, By Technologyr, 2020 - 2028 10.4.12. Rest Of Asia-Pacific 10.4.12.1. Introduction 10.4.12.2. Driving Factors, Opportunity Analyzed and Key Trends 10.4.12.3. Market Size and Forecast, By Platform, 2020 - 2028 10.4.12.4. Market Size and Forecast, By Material Type, 2020 - 2028 10.4.12.5. Market Size and Forecast, By Application, 2020 – 2028 10.4.12.6. Market Size and Forecast, By Technologyr, 2020 - 2028 10.5. Rest Of The World (RoW) 10.5.1. Introduction 10.5.2. Driving Factors, Opportunity Analyzed and Key Trends 10.5.3. Market Size and Forecast, By Platform, 2020 - 2028 10.5.4. Market Size and Forecast, By Material Type, 2020 - 2028 10.5.5. Market Size and Forecast, By Application, 2020 – 2028 10.5.6. Market Size and Forecast, By Technologyr, 2020 - 2028 10.5.7. Market Size and Forecast, By Region, 2020 - 2028 10.5.8. South America 10.5.8.1. Introduction 10.5.8.2. Driving Factors, Opportunity Analyzed and Key Trends 10.5.8.3. Market Size and Forecast, By Platform, 2020 - 2028 10.5.8.4. Market Size and Forecast, By Material Type, 2020 - 2028 10.5.8.5. Market Size and Forecast, By Application, 2020 – 2028 10.5.8.6. Market Size and Forecast, By Technologyr, 2020 - 2028 10.5.9. Middle East & Afirica 10.5.9.1. Introduction 10.5.9.2. Driving Factors, Opportunity Analyzed and Key Trends 10.5.9.3. Market Size and Forecast, By Platform, 2020 - 2028 10.5.9.4. Market Size and Forecast, By Material Type, 2020 - 2028 10.5.9.5. Market Size and Forecast, By Application, 2020 – 2028 10.5.9.6. Market Size and Forecast, By Technologyr, 2020 - 2028 Chapter 11. Competitive Landscape 11.1. Introduction 11.2. Vendor Share Analysis, 2020/Key Players Positioning, 2020 Chapter 12. Company Profiles 12.1. 3D Systems 12.1.1. Business Overview 12.1.2. Financial Analysis 12.1.3. Product Portfolio 12.1.4. Recent Development and Strategies Adopted 12.1.5. SWOT Analysis 12.2. Arcam EBM 12.2.1. Business Overview 12.2.2. Financial Analysis 12.2.3. Product Portfolio 12.2.4. Recent Development and Strategies Adopted 12.2.5. SWOT Analysis 12.3. Arconic 12.3.1. Business Overview 12.3.2. Financial Analysis 12.3.3. Product Portfolio 12.3.4. Recent Development and Strategies Adopted 12.3.5. SWOT Analysis 12.4. Concept Laser 12.4.1. Business Overview 12.4.2. Financial Analysis 12.4.3. Product Portfolio 12.4.4. Recent Development and Strategies Adopted 12.4.5. SWOT Analysis 12.5. CRP Technology 12.5.1. Business Overview 12.5.2. Financial Analysis 12.5.3. Product Portfolio 12.5.4. Recent Development and Strategies Adopted 12.5.5. SWOT Analysis 12.6. EOS 12.6.1. Business Overview 12.6.2. Financial Analysis 12.6.3. Product Portfolio 12.6.4. Recent Development and Strategies Adopted 12.6.5. SWOT Analysis 12.7. ExOne 12.7.1. Business Overview 12.7.2. Financial Analysis 12.7.3. Product Portfolio 12.7.4. Recent Development and Strategies Adopted 12.7.5. SWOT Analysis 12.8. GE Additive 12.8.1. Business Overview 12.8.2. Financial Analysis 12.8.3. Product Portfolio 12.8.4. Recent Development and Strategies Adopted 12.8.5. SWOT Analysis 12.9. GKN Additive 12.9.1. Business Overview 12.9.2. Financial Analysis 12.9.3. Product Portfolio 12.9.4. Recent Development and Strategies Adopted 12.9.5. SWOT Analysis 12.10. Optomec 12.10.1. Business Overview 12.10.2. Financial Analysis 12.10.3. Product Portfolio 12.10.4. Recent Development and Strategies Adopted 12.10.5. SWOT Analysis Chapter 13. Key Takeaways

Connect to Analyst

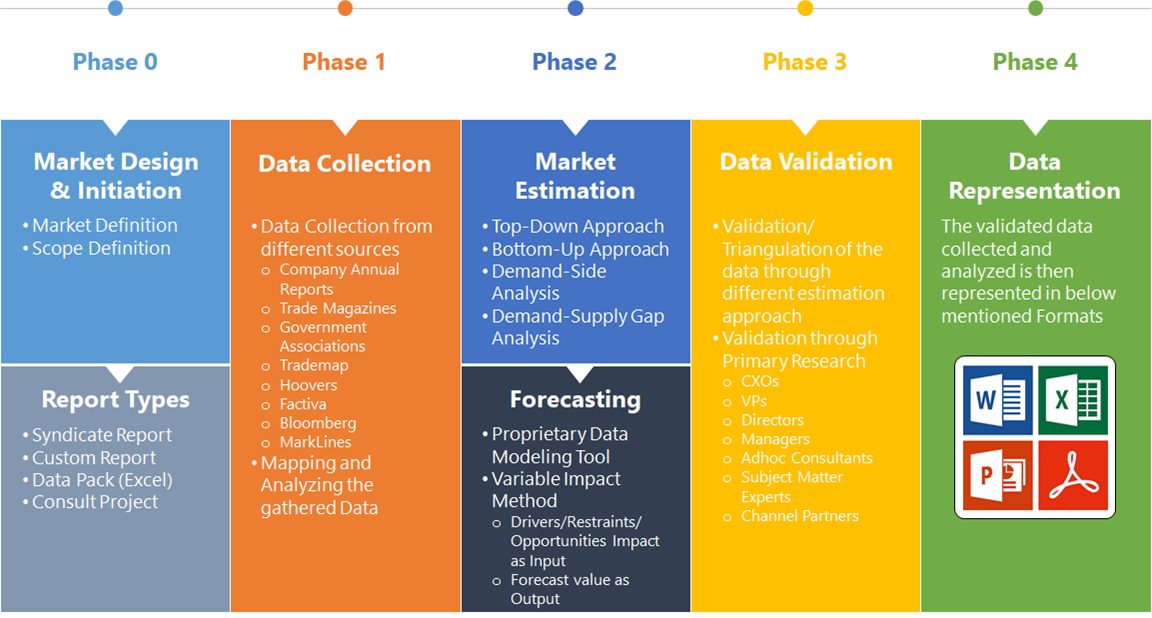

Research Methodology