3D Printing Market Overview

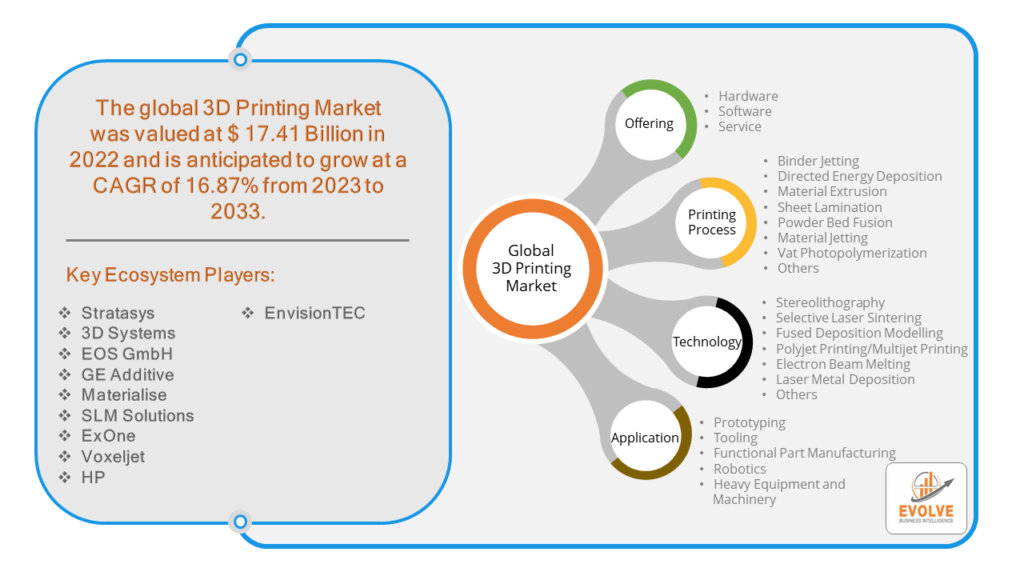

The 3D Printing Market Size is expected to reach USD 38.47 Billion by 2033. The 3D Printing Market industry size accounted for USD 17.41 Billion in 2023 and is expected to expand at a compound annual growth rate (CAGR) of 16.87% from 2023 to 2033. The 3D printing market, also known as the additive manufacturing market, encompasses the industry involved in the creation, distribution, and utilization of 3D printing technology. In 3D printing, physical objects are created layer by layer from digital designs using various materials such as plastics, metals, ceramics, and composites. This market includes the manufacturing of 3D printers, materials used in printing, software for design and printing processes, as well as related services such as prototyping, customization, and production.

The 3D printing market spans across a wide range of industries including aerospace, automotive, healthcare, consumer goods, education, and more, offering innovative solutions for prototyping, rapid manufacturing, customization, and even bioprinting. With continuous advancements in technology and increasing adoption across industries, the 3D printing market is experiencing significant growth and is poised to revolutionize manufacturing processes in the future.

Global 3D Printing Market Synopsis

The COVID-19 pandemic had significant impacts on the 3D printing market. The 3D printing market faced challenges due to disruptions in the global supply chain caused by lockdowns and restrictions on movement. This affected the availability of raw materials and components necessary for manufacturing 3D printers and printing materials. The pandemic prompted a shift in demand for certain products. 3D printing technology offered agility in manufacturing, enabling companies to quickly adapt to changing consumer needs. For instance, there was a surge in demand for personal protective equipment (PPE) such as face shields and respirator parts, which were rapidly produced using 3D printing. With remote work becoming the norm, there was a greater emphasis on distributed manufacturing. 3D printing allowed companies to decentralize production, enabling them to manufacture parts and products closer to the point of need, reducing reliance on centralized manufacturing facilities.

3D Printing Market Dynamics

The major factors that have impacted the growth of 3D Printing Market are as follows:

Drivers:

Ø Technological Advancements

Continuous advancements in 3D printing technology, including improvements in printing speed, precision, and material capabilities, are driving market growth. Innovations such as multi-material printing, bioprinting, and large-scale additive manufacturing are expanding the range of applications for 3D printing. 3D printing offers cost advantages, especially for low-volume production and rapid prototyping. Companies can reduce material wastage, tooling costs, and inventory expenses by adopting additive manufacturing techniques, making it an attractive option for various industries. The ability to create highly customized and personalized products is a significant driver for the 3D printing market. From consumer goods to medical implants, 3D printing enables manufacturers to tailor products to individual preferences and specific requirements, enhancing customer satisfaction and driving demand.

Restraint:

- Perception of Quality and Consistency Concerns

Ensuring consistent quality and dimensional accuracy of 3D-printed parts can be challenging, especially for complex geometries and large-scale production. Variability in printing parameters, material properties, and machine calibration can lead to defects and inconsistencies, requiring careful quality control measures. While 3D printing offers long-term cost savings for certain applications, the initial investment costs for equipment, materials, and software can be prohibitive for some businesses. Small and medium-sized enterprises (SMEs) may find it challenging to justify the upfront expenses associated with implementing 3D printing technology, particularly if they have lower production volumes. While well-suited for rapid prototyping and low-volume production, 3D printing may not be as efficient or cost-effective for mass production of identical parts. Traditional manufacturing methods such as injection molding and machining often offer higher throughput and lower per-unit costs for large production runs, limiting the scalability of 3D printing in certain applications.

Opportunity:

⮚ Digital Inventory and Spare Parts Management

3D printing enables the creation of digital inventories and on-demand production of spare parts, reducing the need for physical stockpiling and minimizing the risk of obsolescence. This presents opportunities for aftermarket services, maintenance, and repair operations, especially in industries such as aerospace, automotive, and healthcare. 3D printing technology is increasingly being integrated into educational curricula at all levels, providing opportunities for students to gain hands-on experience with digital design and manufacturing processes. This fosters a skilled workforce capable of driving innovation and growth in the 3D printing industry and related sectors. As 3D printing technology continues to evolve, new markets and applications are emerging across industries such as construction, food, electronics, and fashion. These nascent markets present opportunities for pioneering companies to explore innovative use cases and capture untapped market segments.

3D Printing Market Segment Overview

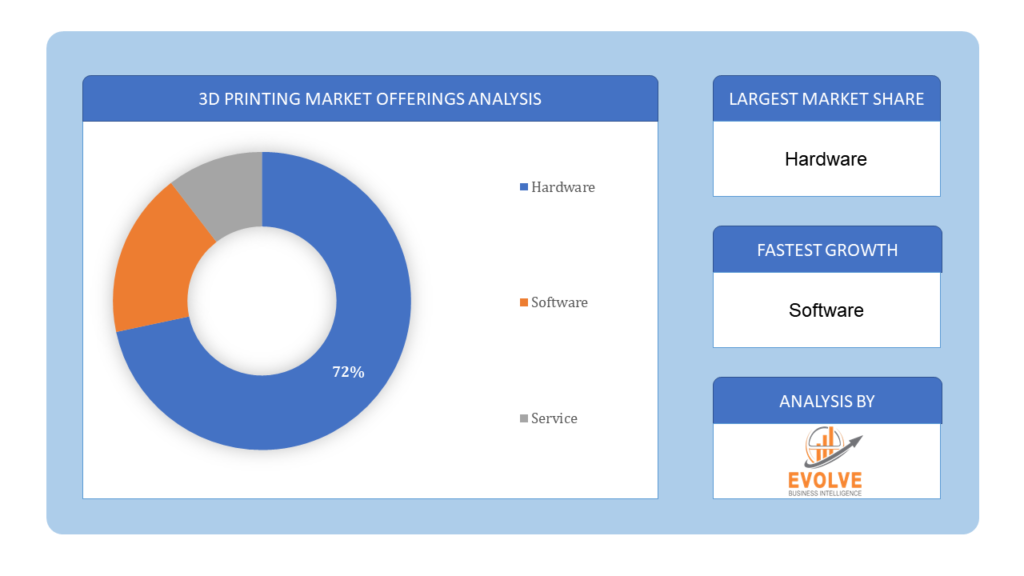

By Offerings

Based on Offerings, the market is segmented based on Hardware, Software and Service. The Hardware segment is dominant the market. The hardware segment encompasses a variety of 3D printing machines, including metal 3D printers, polymers/ceramics 3D printers, and 3D bioprinters. These machines are utilized across numerous industries and applications, and their importance in the additive manufacturing process cannot be overstated. 3D printing is driving a quiet revolution in manufacturing.

Based on Offerings, the market is segmented based on Hardware, Software and Service. The Hardware segment is dominant the market. The hardware segment encompasses a variety of 3D printing machines, including metal 3D printers, polymers/ceramics 3D printers, and 3D bioprinters. These machines are utilized across numerous industries and applications, and their importance in the additive manufacturing process cannot be overstated. 3D printing is driving a quiet revolution in manufacturing.

By Printing Process

Based on Printing Process, the market segment has been divided into Binder Jetting, Directed Energy Deposition, Material Extrusion, Sheet Lamination, Powder Bed Fusion, Material Jetting, Vat Photopolymerization and Others. The Binder Jetting segment is dominant the market. Binder Jetting is known for its high-speed production capabilities, making it suitable for rapid prototyping and large-scale manufacturing applications. The process allows for the simultaneous printing of multiple parts within the same build volume, leading to increased throughput and efficiency.

By Technology

Based on Technology, the market segment has been divided into Stereolithography, Selective Laser Sintering, Fused Deposition Modelling, Multijet Printing, Electron Beam Melting, Laser Metal Deposition and Others. The Stereolithography segment is anticipated to dominant the market. Stereolithography is among the most ancient and widely used printing technologies. Furthermore, the advantages and the convenience associated with stereolithography technology encourage its adoption, technological advancements, and research and development events performed by industry researchers and experts are opening up possibilities for a variety of other reliable and efficient techniques.

By Application

Based on Application, the market segment has been divided into Prototyping, Tooling, Functional Part Manufacturing, Robotics and Heavy Equipment and Machinery. The Prototyping segment is anticipated to dominant the market. This is due to the vast use of the prototyping procedure all over a variety of industry sectors. Prototyping is used extensively in aerospace as well as defense, and automotive industries to precisely develop and design components, and parts along with complex techniques. Manufacturers achieve greater precision and develop more reliable finished products by using prototyping.

By Vertical

Based on Vertical, the market segment has been divided into Automotive, Aerospace and Defense, Healthcare, Architecture and Construction, Consumer, Industrial, Energy and Others. The automotive sector is anticipated to record a healthy growth. The demand for electric vehicles as a counter to pollution amid environmental concerns, plus tightened production cycles, has led to a need for the design process to be speeded up while costs are cut. However, regulatory issues around widespread use of 3D printing remains a concern. That said, there is significant usage of 3D printing now underway in the automotive sector and a desire to track 3D printing progress closely.

Global 3D Printing Market Regional Analysis

Based on region, the global 3D Printing Market has been divided into North America, Europe, Asia-Pacific, the Middle East & Africa, and Latin America. North America is projected to dominate the use of the 3D Printing Market followed by the Asia-Pacific and Europe regions.

3D Printing North America Market

North America holds a dominant position in the 3D Printing Market. North America, particularly the United States, has been a leader in the 3D printing market in terms of both adoption and innovation. The region is home to numerous 3D printing companies, research institutions, and end-user industries across sectors such as aerospace, automotive, healthcare, and consumer goods. Strong government support for advanced manufacturing technologies, robust R&D infrastructure, and a mature industrial base contribute to the growth of the 3D printing market in North America.

3D Printing Asia-Pacific Market

The Asia-Pacific region has indeed emerged as the fastest-growing market for the 3D Printing Market industry. The Asia-Pacific region is experiencing rapid growth in the 3D printing market, driven by factors such as increasing industrialization, technological advancements, and government initiatives to promote advanced manufacturing. Countries like China, Japan, South Korea, and Singapore are investing heavily in 3D printing technologies and infrastructure to enhance their competitiveness in global markets. The region is witnessing significant adoption of 3D printing in industries such as electronics, healthcare, automotive, and aerospace.

Competitive Landscape

The global 3D Printing Market is highly competitive, with numerous players offering a wide range of software solutions. The competitive landscape is characterized by the presence of established companies, as well as emerging startups and niche players. To increase their market position and attract a wide consumer base, the businesses are employing various strategies, such as product launches, and strategic alliances.

Prominent Players:

- Stratasys

- 3D Systems

- EOS GmbH

- GE Additive

- Materialise

- SLM Solutions

- ExOne

- Voxeljet

- HP

- EnvisionTEC

Scope of the Report

Global 3D Printing Market, by Offerings

- Hardware

- Software

- Service

Global 3D Printing Market, by Printing Process

- Binder Jetting

- Directed Energy Deposition

- Material Extrusion

- Sheet Lamination

- Powder Bed Fusion

- Material Jetting

- Vat Photopolymerization

- Others

Global 3D Printing Market, by Technology

- Stereolithography

- Selective Laser Sintering

- Fused Deposition Modelling

- Multijet Printing

- Electron Beam Melting

- Laser Metal Deposition

- Others

Global 3D Printing Market, by Application

- Prototyping

- Tooling

- Functional Part Manufacturing

- Robotics

- Heavy Equipment and Machinery

Global 3D Printing Market, by Vertical

- Automotive

- Aerospace and Defense

- Healthcare

- Architecture and Construction

- Consumer

- Industrial

- Energy

- Others

Global 3D Printing Market, by Region

- North America

- US

- Canada

- Mexico

- Europe

- UK

- Germany

- France

- Italy

- Spain

- Benelux

- Nordic

- Rest of Europe

- Asia Pacific

- China

- Japan

- South Korea

- Indonesia

- Austalia

- Malaysia

- India

- Rest of Asia Pacific

- South America

- Brazil

- Argentina

- Rest of SouthAmerica

- Middle East &Africa

- Saudi Arabia

- UAE

- Egypt

- SouthAfrica

- Rest of Middle East & Africa

| Parameters | Indicators |

|---|---|

| Market Size | 2033: $38.47 Billion |

| CAGR | 16.87% CAGR (2023-2033) |

| Base year | 2022 |

| Forecast Period | 2023-2033 |

| Historical Data | 2021 |

| Report Coverage | Revenue Forecast, Competitive Landscape, Growth Factors, and Trends |

| Key Segmentations | Offerings, Printing Process, Technology, Application, Vertical |

| Geographies Covered | North America, Europe, Asia-Pacific, Latin America, Middle East, Africa |

| Key Vendors | Stratasys, 3D Systems, EOS GmbH, GE Additive, Materialise, SLM Solutions, ExOne, Voxeljet, HP and EnvisionTEC. |

| Key Market Opportunities | • Digital Inventory and Spare Parts Management • Education and Training |

| Key Market Drivers | • Technological Advancements • Customization and Personalization |

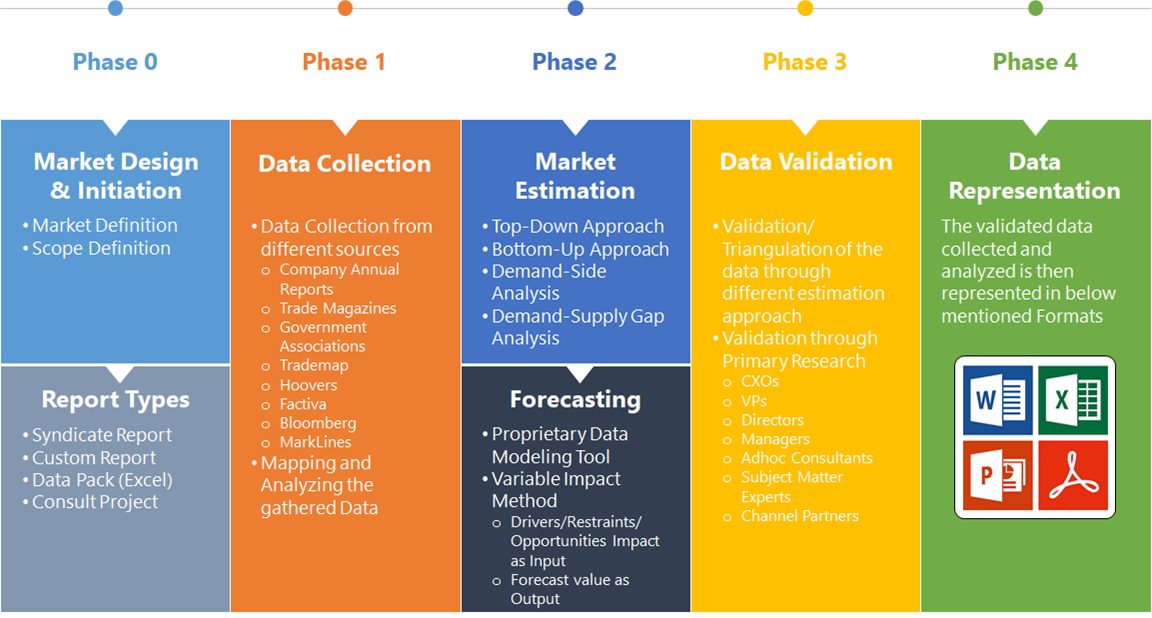

REPORT CONTENT BRIEF:

- High-level analysis of the current and future 3D Printing Market trends and opportunities

- Detailed analysis of current market drivers, restraining factors, and opportunities in the future

- 3D Printing Market historical market size for the year 2021, and forecast from 2023 to 2033

- 3D Printing Market share analysis at each product level

- Competitor analysis with detailed insight into its product segment, Government & Defense strength, and strategies adopted.

- Identifies key strategies adopted including product launches and developments, mergers and acquisitions, joint ventures, collaborations, and partnerships as well as funding taken and investment done, among others.

- To identify and understand the various factors involved in the global 3D Printing Market affected by the pandemic

- To provide a detailed insight into the major companies operating in the market. The profiling will include the Government & Defense health of the company’s past 2-3 years with segmental and regional revenue breakup, product offering, recent developments, SWOT analysis, and key strategies.