Blog

Machine Condition Monitoring Market Grows: 8.32% CAGR

Evolve Business Intelligence has published a research report on the Global Machine Condition Monitoring Market, 2021–2034. The global Machine Condition Monitoring market is projected to exhibit a CAGR of around 4.41%during the forecast period of 2021 to 2034.

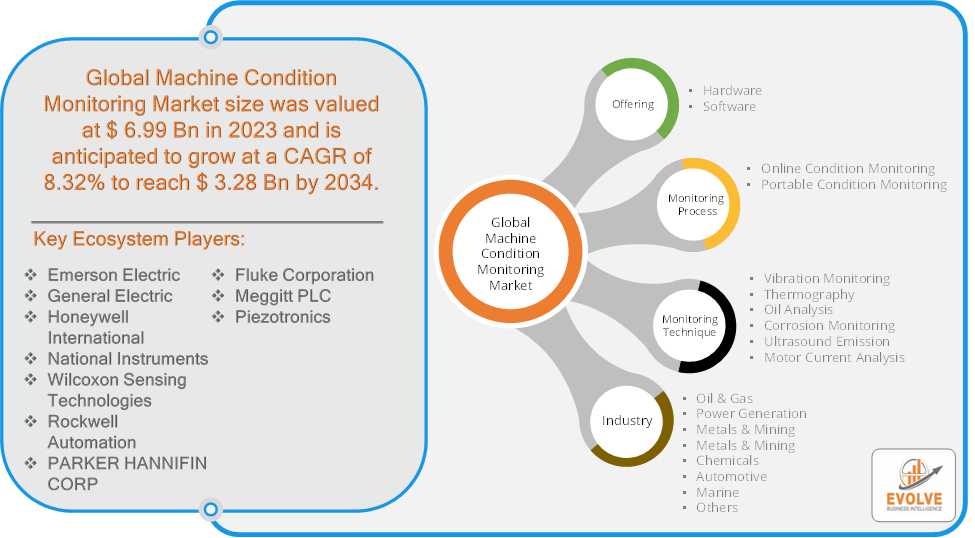

Evolve Business Intelligence has recognized the following companies as the key players in the global Machine Condition Monitoring Market: Emerson Electric, General Electric, Honeywell International, National Instruments, Wilcoxon Sensing Technologies, Rockwell Automation, PARKER HANNIFIN CORP, Fluke Corporation, Meggitt PLC, Piezotronics

The Machine Condition Monitoring Market size accounted for USD 3.28 Billion in 2023 and is estimated to account for 4.79 Billion in 2024. The Market is expected to reach USD 6.99 Billion by 2034 growing at a compound annual growth rate (CAGR) of 8.32% from 2024 to 2034. The technologies and methods used to evaluate the performance and condition of machinery across a range of industries are the main focus of the machine condition monitoring market. This market includes a variety of solutions, such as oil analysis, vibration analysis, thermal imaging, and acoustic emission monitoring. By assisting in the early detection of possible problems before they result in equipment failure, these instruments enable predictive maintenance plans that can lower maintenance costs and downtime. The market is driven by the manufacturing and industrial sectors’ growing need for operational efficiency, sustainability, and safety. Manufacturing facilities, power plants, and the transportation industry are important end customers. The incorporation of smart sensors and data analytics further boosts monitoring capabilities as industries embrace the Internet of Things (IoT), hence driving market expan

Download the full report now to discover market trends, opportunities, and strategies for success.

Segmental Analysis

The global Machine Condition Monitoring market has been segmented based on Offering, Monitoring Process, Monitoring Technique , Industry

Based on the Offering, the market is segmented based on Hardware, Software. Hardware dominates the segment, as it includes essential components like sensors and monitoring devices that are critical for collecting data on machine performance and condition

Based on Monitoring Process, the market has been divided into Online Condition Monitoring, Portable Condition Monitoring. Online Condition Monitoring is the dominant segment, as it allows for real-time, continuous data collection and analysis, enabling proactive maintenance and immediate response to equipment issues

Based on the Monitoring Technique , the market has been divided into Vibration Monitoring, Thermography, Oil Analysis, Corrosion Monitoring, Ultrasound Emission, Motor Current Analysis. Vibration Monitoring is the dominant segment, as it is widely used for its effectiveness in detecting early signs of equipment failure and its applicability across various industries.

Based on Industry , the market has been divided into Oil & Gas, Power Generation, Metals & Mining, Chemicals, Automotive, Marine, Others. the Oil & Gas industry typically dominates due to its critical reliance on equipment performance and safety, necessitating continuous monitoring to prevent costly downtimes and accidents.

Regional Analysis

The Machine Condition Monitoring market is divided into five regions: North America, Europe, Asia-Pacific, South America, and the Middle East, &Africa. The North American region holds a dominant position in the Machine Condition Monitoring market. This market will be dominated by the machine condition monitoring sector in North America. It is anticipated that the United States and Canada will have substantial growth opportunity in comparison to the robust demand from the power generation, aerospace, oil & gas, marine, and food & beverage industries. Vibration monitoring has been a popular technique for oil condition monitoring in the equipment lubricants used on oil and gas platforms. The Asia-Pacific region is witnessing rapid growth and emerging as a significant market for the Machine Condition Monitoring industry. The market for machine condition monitoring in Asia-Pacific is anticipated to expand at the quickest rate between 2023 and 2032 (CAGR of ). This segment’s substantial market share can be attributed to several factors, including the substantial increase in industrial robot deployment, the growing need for automation, and the presence of high-production countries like China and Japan. Furthermore, in the Asia-Pacific region, the machine condition monitoring market in Japan was increasing at the fastest rate, while the market in China held the greatest market share.