Steel and Alloy Casting Valves Market Overview

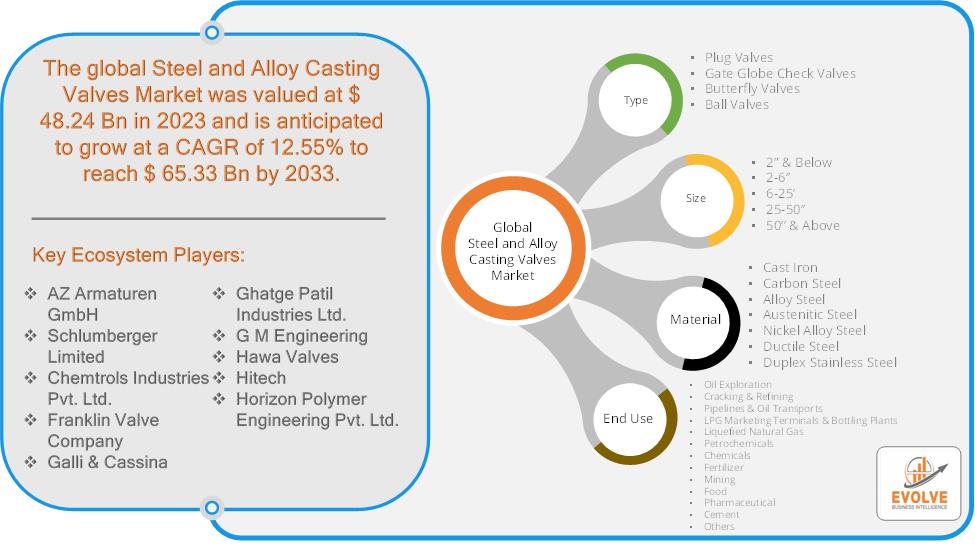

Steel and Alloy Casting Valves Market Size is expected to reach USD 65.33 Billion by 2033. The Steel and Alloy Casting Valves industry size accounted for USD 48.24 Billion in 2023 and is expected to expand at a compound annual growth rate (CAGR) of 12.55% from 2023 to 2033. The Steel and Alloy Casting Valves Market focuses on the production and distribution of valves made from steel and various alloys, offering superior strength, durability, and resistance to extreme conditions. These valves are crucial for controlling the flow of liquids, gases, and slurries in industries such as oil and gas, power generation, chemical processing, and water treatment. Their high performance in high-pressure and high-temperature environments makes them indispensable in industrial applications where reliability and longevity are critical. The market is driven by increasing industrialization and the demand for robust, corrosion-resistant valves.

Global Steel and Alloy Casting Valves Market Synopsis

The COVID-19 pandemic has led to supply chain disruptions leading to supply shortages or lower demand in the Steel and Alloy Casting Valves market. The travel restrictions and social-distancing measures have resulted in a sharp drop in consumer and business spending and this pattern is to continue for some time. The end-user trend and preferences have changed due to the pandemic and have resulted in manufacturers, developers, and service providers to adopt various strategies to stabilize the company.

Global Steel and Alloy Casting Valves Market Dynamics

The major factors that have impacted the growth of Steel and Alloy Casting Valves are as follows:

Drivers:

⮚ Technological Advancements

Innovations in casting technologies and materials science have led to the development of valves with enhanced performance characteristics. Advances in metallurgy, such as the creation of more corrosion-resistant alloys and improved casting techniques, allow for the production of valves that can operate efficiently in high-pressure, high-temperature, and highly corrosive environments, driving market growth.

Restraint:

- Technological Barriers and Innovation Challenges

While technological advancements are a driver for the market, they can also act as a restraint. The rapid pace of innovation requires manufacturers to continuously invest in research and development to stay competitive. However, not all companies have the resources to keep up with these technological demands. Additionally, the adoption of new technologies may be slow due to the need for industry-wide standardization, testing, and certification, creating barriers to market entry for smaller players.

Opportunity:

⮚ Technological Advancements and Innovations

Advances in casting technologies, materials science, and valve design offer opportunities to develop new and improved products. Innovations such as the development of advanced alloys with enhanced properties (e.g., higher corrosion resistance, better high-temperature performance) and the integration of smart technologies (e.g., IoT-enabled valves for real-time monitoring) can open new market segments and applications. Companies that invest in research and development can gain a competitive edge and capture market share with cutting-edge products.

Steel and Alloy Casting Valves Market Segment Overview

Based on the Type, the market is segmented based on Plug Valves, Gate Globe Check Valves, Butterfly Valves, Ball Valves. Ball Valves often dominate due to their reliable performance, ease of operation, and suitability for a wide range of applications, including high-pressure and high-temperature environments.

By Size

Based on Size, the market has been divided into 2” & Below, 2-6’’, 6-25’’, 25-50’’, 50’’ & Above. the 6-25’’ size segment typically dominates, as it caters to a broad range of industrial applications requiring mid-sized valves for various operational needs.

By Material

Based on the Material, the market has been divided into Cast Iron, Carbon Steel, Alloy Steel, Austenitic Steel, Nickel Alloy Steel, Ductile Steel, Duplex Stainless Steel. Carbon Steel often dominates due to its cost-effectiveness and versatile performance across a wide range of industrial applications, making it a preferred choice for many valve manufacturers.

By End Use

Based on End Use, the market has been divided into Oil Exploration, Cracking & Refining, Pipelines & Oil Transports, LPG Marketing Terminals & Bottling Plants, Liquefied Natural Gas, Petrochemicals, Chemicals, Fertilizer, Mining, Food, Pharmaceutical, Cement, Others. the Oil Exploration segment often dominates due to its high demand for durable and reliable valves that can withstand harsh conditions in exploration and extraction processes. This sector’s need for robust equipment drives significant market share compared to other end-use segments.

Global Steel and Alloy Casting Valves Market Regional Analysis

Based on region, the market has been divided into North America, Europe, Asia-Pacific, the Middle East & Africa, and Latin America. The area of North America is anticipated to dominate the market for the usage of Steel and Alloy Casting Valves, followed by those in Asia-Pacific and Europe.

The North American region holds a dominant position in the Steel and Alloy Casting Valves market. In North America, the Steel and Alloy Casting Valves Market is driven by robust industrial activity, including oil and gas extraction, power generation, and chemical processing. The region’s focus on infrastructure upgrades, energy sector advancements, and stringent safety regulations boosts demand for high-quality valves. Additionally, North America’s emphasis on technological innovation and advanced manufacturing processes supports the growth of the market. The presence of major valve manufacturers and a well-established supply chain further strengthens the market in this region.

Steel and Alloy Casting Valves Asia Pacific Market

The Asia-Pacific region is witnessing rapid growth and emerging as a significant market for the Steel and Alloy Casting Valves industry. In the Asia-Pacific region, the Steel and Alloy Casting Valves Market is propelled by rapid industrialization, infrastructure development, and growing energy needs. Countries like China and India drive demand through extensive investments in oil and gas exploration, power generation, and water treatment facilities. The region’s expanding manufacturing base and increasing urbanization also contribute to the market’s growth.

Competitive Landscape

The competitive landscape includes key players (tier 1, tier 2, and local) having a presence across the globe. Companies such as AZ Armaturen GmbH, Schlumberger Limited, Chemtrols Industries Pvt. Ltd., Franklin Valve Company, and Galli & Cassina are some of the leading players in the global Steel and Alloy Casting Valves Industry. These players have adopted partnership, acquisition, expansion, and new product development, among others as their key strategies.

Key Market Players:

- AZ Armaturen GmbH

- Schlumberger Limited

- Chemtrols Industries Pvt. Ltd.

- Franklin Valve Company

- Galli & Cassina

- Ghatge Patil Industries Ltd.

- G M Engineering

- Hawa Valves

- Hitech

- Horizon Polymer Engineering Pvt. Ltd.

Key Development:

In September 2022, Horizon Polymer Engineering Pvt. Ltd. focused on expanding its product portfolio and enhancing its manufacturing capabilities for steel and alloy casting valves, aiming to better meet the needs of various industrial applications.

Scope of the Report

Global Steel and Alloy Casting Valves Market, by Type

- Plug Valves

- Gate Globe Check Valves

- Butterfly Valves

- Ball Valves

Global Steel and Alloy Casting Valves Market, by Size

- 2” & Below

- 2-6’’

- 6-25’

- 25-50’’

- 50’’ & Above

Global Steel and Alloy Casting Valves Market, by Material

- Cast Iron

- Carbon Steel

- Alloy Steel

- Austenitic Steel

- Nickel Alloy Steel

- Ductile Steel

- Duplex Stainless Steel

Global Steel and Alloy Casting Valves Market, by End Use

- Oil Exploration

- Cracking & Refining

- Pipelines & Oil Transports

- LPG Marketing Terminals & Bottling Plants

- Liquefied Natural Gas

- Petrochemicals

- Chemicals

- Fertilizer

- Mining

- Food

- Pharmaceutical

- Cement

- Others

Global Steel and Alloy Casting Valves Market, by Region

- North America

- US

- Canada

- Mexico

- Europe

- UK

- Germany

- France

- Italy

- Spain

- Benelux

- Nordic

- Rest of Europe

- Asia Pacific

- China

- Japan

- South Korea

- Indonesia

- Austalia

- Malaysia

- India

- Rest of Asia Pacific

- South America

- Brazil

- Argentina

- Rest of South America

- Middle East & Africa

- Saudi Arabia

- UAE

- Egypt

- South Africa

- Rest of Middle East & Africa

| Parameters | Indicators |

|---|---|

| Market Size | 2033: USD 65.33 Billion |

| CAGR (2023-2033) | 12.55% |

| Base year | 2022 |

| Forecast Period | 2023-2033 |

| Historical Data | 2021 (2017 to 2020 On Demand) |

| Report Coverage | Revenue Forecast, Competitive Landscape, Growth Factors, and Trends |

| Key Segmentations | Type, Size, Material, End Use |

| Geographies Covered | North America, Europe, Asia-Pacific, South America, Middle East, Africa |

| Key Vendors | AZ Armaturen GmbH, Schlumberger Limited, Chemtrols Industries Pvt. Ltd., Franklin Valve Company, Galli & Cassina, Ghatge Patil Industries Ltd., G M Engineering, Hawa Valves, Hitech, Horizon Polymer Engineering Pvt. Ltd. |

| Key Market Opportunities | Growing E-commerce Industry |

| Key Market Drivers | Increasing Consumer Demand

Technological Advancements |

REPORT CONTENT BRIEF:

- High-level analysis of the current and future Steel and Alloy Casting Valves Industry trends and opportunities

- Detailed analysis of current market drivers, restraining factors, and opportunities analysis in the future

- Historical market size for the year 2021, and forecast from 2023 to 2033

- Steel and Alloy Casting Valves market share analysis for each segment

- Competitor analysis with a comprehensive insight into its product segment, financial strength, and strategies adopted.

- Identifies key strategies adopted by the key players including new product development, mergers and acquisitions, joint ventures, collaborations, and partnerships.

- To identify and understand the various factors involved in the global Steel and Alloy Casting Valves market affected by the pandemic

- To provide year-on-year growth from 2022 to 2033

- To provide short-term, long-term, and overall CAGR comparison from 2022 to 2033.

- Provide Total Addressable Market (TAM) for the Global Steel and Alloy Casting Valves Market.

Frequently Asked Questions (FAQ)

What are the 10 Years CAGR (2023 to 2033) of the global Steel and Alloy Casting Valves market?

The global Steel and Alloy Casting Valves market is growing at a CAGR of ~12.55% over the next 10 years

Which region has the highest growth rate in the market of Steel and Alloy Casting Valves?

Asia Pacific is expected to register the highest CAGR during 2023-2033

Which region accounted for the largest share of the market of Steel and Alloy Casting Valves?

North America holds the largest share in 2022

Major Key Players in the Market of Steel and Alloy Casting Valves?

AZ Armaturen GmbH, Schlumberger Limited, Chemtrols Industries Pvt. Ltd., Franklin Valve Company, Galli & Cassina, Ghatge Patil Industries Ltd., G M Engineering, Hawa Valves, Hitech, and Horizon Polymer Engineering Pvt. Ltd. are the major companies operating in the Steel and Alloy Casting Valves Industry.

Do you offer Post Sale Support?

Yes, we offer 16 hours of analyst support to solve the queries

Do you deliver sections of a report?

Yes, we do provide regional as well as country-level reports. Other than this we also provide a sectional report. Please get in contact with our sales representatives.