Smart Factory Market Overview

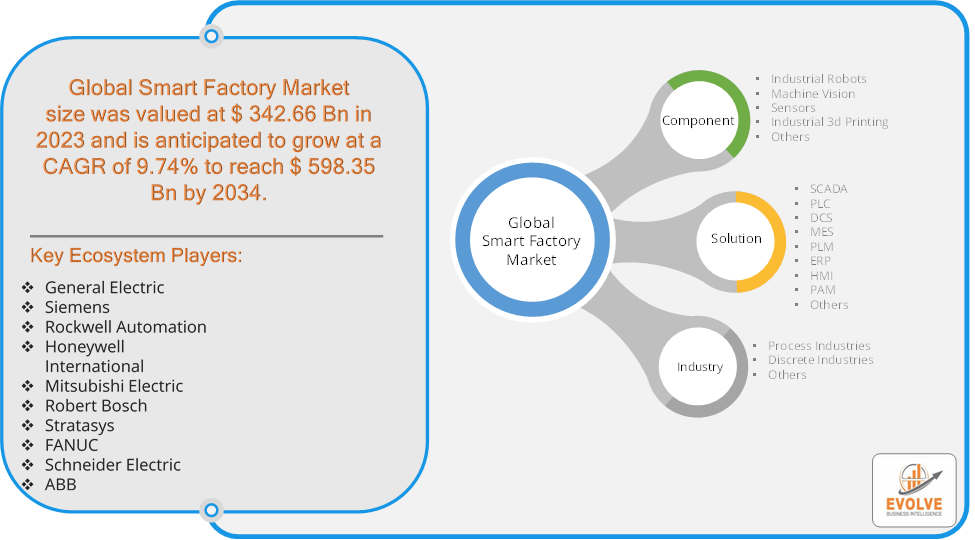

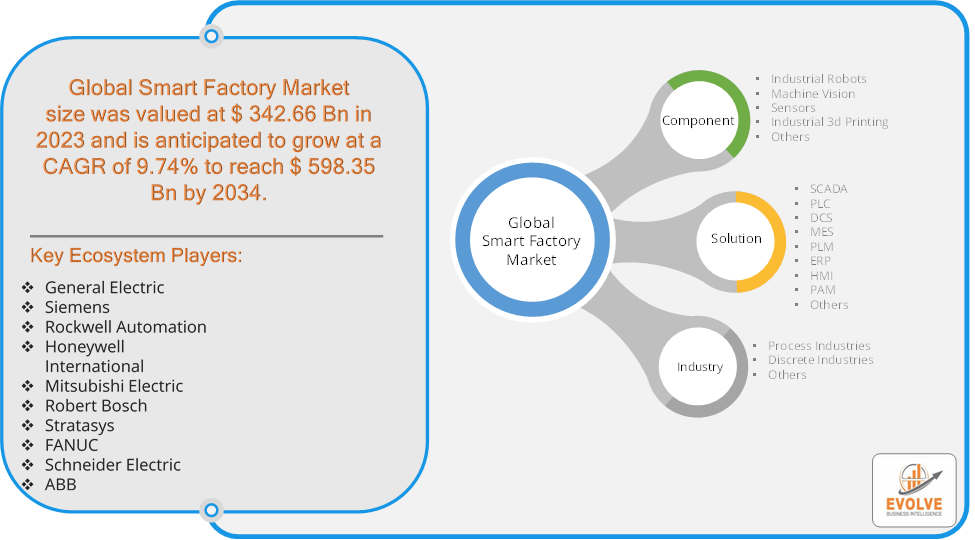

The Smart Factory Market size accounted for USD 342.66 Billion in 2023 and is estimated to account for 345.21 Billion in 2024. The Market is expected to reach USD 598.35 Billion by 2034 growing at a compound annual growth rate (CAGR) of 9.74% from 2024 to 2034. The smart factory market refers to the global industry involved in the development, implementation, and sale of technologies and solutions that enable manufacturing facilities to become more efficient, flexible, and connected. These technologies often leverage the Internet of Things (IoT), artificial intelligence (AI), machine learning, robotics, and automation to optimize production processes and enhance overall operational efficiency.

In a smart factory, machines and systems communicate with each other, share data, and make autonomous decisions, resulting in more efficient and responsive production environments. The market is driven by the demand for greater productivity, customization, reduced downtime, and improved safety in manufacturing processes.

Global Smart Factory Market Synopsis

The major factors that have impacted the growth of Smart Factory Market are as follows:

Drivers:

Ø Rising Need for Data-Driven Decision Making

The use of big data analytics and machine learning in smart factories allows manufacturers to analyze massive amounts of data, leading to more informed decision-making. This data-driven approach helps in optimizing production, managing supply chains, and ensuring quality control. Smart factories help reduce operational costs through energy efficiency, resource optimization, and reduced downtime. The ability to monitor equipment performance in real-time leads to better maintenance strategies, minimizing repair costs and extending equipment lifespan.

Restraint:

- Perception of Data Security and Cybersecurity Risks

As smart factories rely heavily on data exchange between interconnected devices, they become more vulnerable to cyberattacks and data breaches. Ensuring robust cybersecurity measures and protecting sensitive manufacturing data is a growing concern that can deter adoption. Smart factory operations require a highly skilled workforce capable of managing and maintaining advanced technologies such as AI, IoT, and robotics. The shortage of personnel with expertise in these areas can slow down the deployment and optimization of smart factory systems.

Opportunity:

⮚ Advancement in AI and Machine Learning Applications

The continued advancements in artificial intelligence (AI) and machine learning (ML) provide opportunities for developing more sophisticated smart factory systems. These technologies can enable predictive analytics, real-time decision-making, and autonomous manufacturing, opening up new possibilities for optimizing production processes. Growing environmental concerns and regulatory pressure to reduce carbon footprints present opportunities for smart factories to promote sustainable and energy-efficient manufacturing. Smart factories can optimize resource use, reduce waste, and improve energy management, aligning with global sustainability goals.

Smart Factory Market Segment Overview

Based on Component, the market is segmented based on Industrial Robots, Machine Vision, Sensors, Industrial 3d Printing and Others. The Industrial segment dominant the market. These advanced machines are revolutionizing the manufacturing industry by combining automation, connectivity, and artificial intelligence. Industrial robots offer numerous benefits, such as increased productivity, enhanced precision, reduced costs, and improved safety.

By Solution

Based on Solution, the market segment has been divided into SCADA, PLC, DCS, MES, PLM, ERP, HMI, PAM and Others. The Manufacturing Execution Systems (MES) segment dominant the market. MES acts as a bridge between the shop floor and the enterprise, enabling seamless coordination and optimization of manufacturing processes. These systems integrate various aspects of production, including planning, scheduling, resource allocation, quality control, and data management. Manufacturers can achieve enhanced visibility and control over their operations by implementing MES in smart factories.

By Industry

Based on Industry, the market segment has been divided into Process Industries, Discrete Industries and Others. The Process Industries segment dominant the market.

Global Smart Factory Market Regional Analysis

Based on region, the global Smart Factory Market has been divided into North America, Europe, Asia-Pacific, the Middle East & Africa, and Latin America. North America is projected to dominate the use of the Smart Factory Market followed by the Asia-Pacific and Europe regions.

North America holds a dominant position in the Smart Factory Market. North America, particularly the U.S., is a major player in the Smart Factory Market due to its strong focus on automation, digitalization, and advanced manufacturing technologies. The region is home to some of the largest technology providers and manufacturing firms that are early adopters of Industry 4.0, IoT, AI, and robotics in manufacturing and the U.S. government’s support for innovation in smart manufacturing through initiatives such as the Smart Manufacturing Leadership Coalition (SMLC) and other funding programs promotes growth in this region. There is also a strong demand for customized products and sustainable manufacturing practices, further fueling the market.

Smart Factory Asia-Pacific Market

The Asia-Pacific region has indeed emerged as the fastest-growing market for the Smart Factory Market industry. The Asia-Pacific region, led by China, Japan, South Korea, and India, is experiencing rapid growth in smart factory adoption due to ongoing industrialization, rising demand for automation, and government initiatives promoting smart manufacturing. China’s Made in China 2025 initiative and Japan’s focus on robotics and automation are key growth drivers and Asia-Pacific is a global manufacturing hub, with significant investments in automotive, electronics, semiconductors, and consumer goods industries. These sectors are rapidly adopting smart factory solutions to enhance productivity, reduce costs, and meet rising consumer demand.

Competitive Landscape

The global Smart Factory Market is highly competitive, with numerous players offering a wide range of software solutions. The competitive landscape is characterized by the presence of established companies, as well as emerging startups and niche players. To increase their market position and attract a wide consumer base, the businesses are employing various strategies, such as product launches, and strategic alliances.

Prominent Players:

- General Electric

- Siemens

- Rockwell Automation

- Honeywell International

- Mitsubishi Electric

- Robert Bosch

- Stratasys

- FANUC

- Schneider Electric

- ABB

Key Development

In October 2022, ABB announced that Accelleron Industries AG, a pioneer in high-power turbochargers for mission-critical applications, has been authorized to start trading on the SIX Swiss Exchange in Zurich under the ticker symbol “ACLN.” This is done to complete Accelleron’s spin-off from ABB.

Scope of the Report

Global Smart Factory Market, by Component

- Industrial Robots

- Machine Vision

- Sensors

- Industrial 3d Printing

- Others

Global Smart Factory Market, by Solution

- SCADA

- PLC

- DCS

- MES

- PLM

- ERP

- HMI

- PAM

- Others

Global Smart Factory Market, by Industry

- Process Industries

- Discrete Industries

- Others

Global Smart Factory Market, by Region

- North America

- US

- Canada

- Mexico

- Europe

- UK

- Germany

- France

- Italy

- Spain

- Benelux

- Nordic

- Rest of Europe

- Asia Pacific

- China

- Japan

- South Korea

- Indonesia

- Austalia

- Malaysia

- India

- Rest of Asia Pacific

- South America

- Brazil

- Argentina

- Rest of South America

- Middle East & Africa

- Saudi Arabia

- UAE

- Egypt

- South Africa

- Rest of Middle East & Africa

| Parameters | Indicators |

|---|---|

| Market Size | 2034: USD 598.35 Billion |

| CAGR (2024-2034) | 9.74% |

| Base year | 2022 |

| Forecast Period | 2024-2034 |

| Historical Data | 2021 (2017 to 2020 On Demand) |

| Report Coverage | Revenue Forecast, Competitive Landscape, Growth Factors, and Trends |

| Key Segmentations | Component, Solution, Industry. |

| Geographies Covered | North America, Europe, Asia-Pacific, South America, Middle East, Africa |

| Key Vendors | General Electric, Siemens, Rockwell Automation, Honeywell International, Mitsubishi Electric, Robert Bosch, Stratasys, FANUC, Schneider Electric and ABB |

| Key Market Opportunities | · Advancement in AI and Machine Learning Applications |

| Key Market Drivers | · Rising Need for Data-Driven Decision Making

· Cost Reduction and Operational Efficiency |

REPORT CONTENT BRIEF:

- High-level analysis of the current and future Smart Factory Market trends and opportunities

- Detailed analysis of current market drivers, restraining factors, and opportunities in the future

- Smart Factory Market historical market size for the year 2021, and forecast from 2023 to 2033

- Smart Factory Market share analysis at each product level

- Competitor analysis with detailed insight into its product segment, Government & Defense strength, and strategies adopted.

- Identifies key strategies adopted including product launches and developments, mergers and acquisitions, joint ventures, collaborations, and partnerships as well as funding taken and investment done, among others.

- To identify and understand the various factors involved in the global Smart Factory Market affected by the pandemic

- To provide a detailed insight into the major companies operating in the market. The profiling will include the Government & Defense health of the company’s past 2-3 years with segmental and regional revenue breakup, product offering, recent developments, SWOT analysis, and key strategies.

Frequently Asked Questions (FAQ)

What is the growth rate of the global Smart Factory Market?

The global Smart Factory Market is growing at a CAGR of 9.74% over the next 10 years

Which region has the highest growth rate in the market of Smart Factory Market?

Asia Pacific is expected to register the highest CAGR during 2024-2034

Which region has the largest share of the global Smart Factory Market?

North America holds the largest share in 2022

Who are the key players in the global Smart Factory Market?

General Electric, Siemens, Rockwell Automation, Honeywell International, Mitsubishi Electric, Robert Bosch, Stratasys, FANUC, Schneider Electric and ABB. are the major companies operating in the market.

Do you offer Post Sale Support?

Yes, we offer 16 hours of analyst support to solve the queries

Do you sell particular sections of a report?

Yes, we provide regional as well as country-level reports. Other than this we also provide a sectional report. Please get in contact with our sales representatives.