Pneumatic Conveying System Market Overview

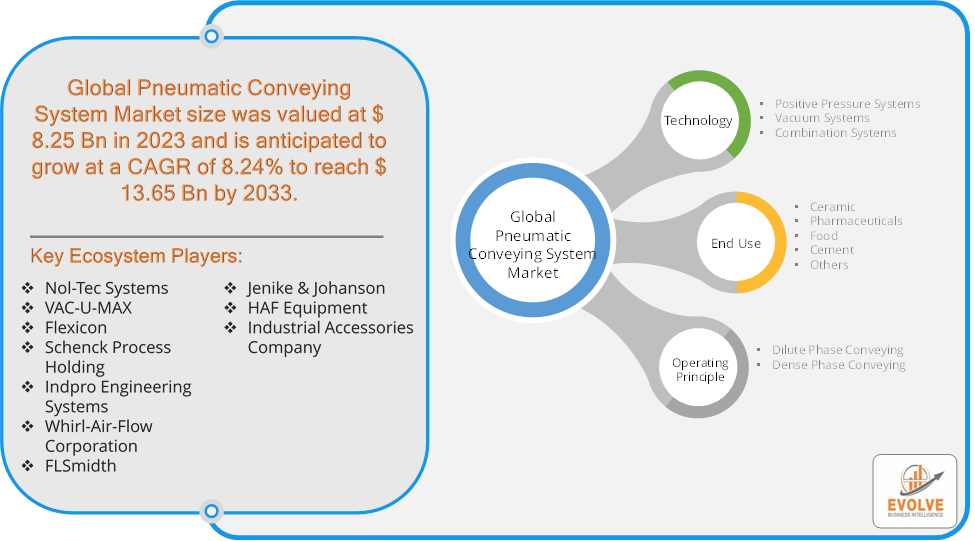

The Pneumatic Conveying System Market Size is expected to reach USD 13.65 Billion by 2033. The Pneumatic Conveying System Market industry size accounted for USD 8.25 Billion in 2023 and is expected to expand at a compound annual growth rate (CAGR) of 8.24% from 2023 to 2033. The Pneumatic Conveying System Market involves the study and analysis of systems used to transport bulk materials through pipes using air or other gases. These systems are essential in various industries, including manufacturing, food processing, pharmaceuticals, and mining, for moving powders, granules, and other bulk materials efficiently.

The pneumatic conveying systems offer a reliable and efficient solution for transporting a wide range of materials in various industries.

Global Pneumatic Conveying System Market Synopsis

The COVID-19 pandemic had a significant impact on the Pneumatic Conveying System Market. Lockdowns and restrictions led to delays in the supply of Operating Principles and raw materials. There was a surge in demand for pneumatic conveying systems in the healthcare and pharmaceutical sectors due to the need for efficient handling of medical supplies, pharmaceuticals, and vaccines. The food and beverage industry also saw increased demand for automated systems to ensure continuity in production and distribution. The pandemic affected workforce availability due to health concerns and restrictions, impacting the ability to maintain and operate systems. There was a heightened emphasis on hygiene and sanitation, leading to increased demand for systems that can be easily cleaned and maintained. The pandemic accelerated the adoption of new technologies and innovations in pneumatic conveying systems, including remote monitoring and control systems to ensure operational continuity despite reduced on-site personnel.

Pneumatic Conveying System Market Dynamics

The major factors that have impacted the growth of Pneumatic Conveying System Market are as follows:

Drivers:

Ø Technological Advancements

Advances in pneumatic conveying technology, such as improved system design, energy efficiency, and automation, drive market growth. Increasing integration with Internet of Things (IoT) for remote monitoring and control of systems. Pneumatic conveying systems can reduce operational costs associated with manual handling and maintenance compared to other material handling methods. Technological advancements have led to more energy-efficient pneumatic systems, making them a cost-effective choice.

Restraint:

- Perception of High Initial Investment Costs and System Limitations

The initial costs of purchasing and installing pneumatic conveying systems can be high, which may deter smaller businesses or those with limited budgets. The complexity of installation and integration into existing systems can increase overall costs. Pneumatic systems may not be suitable for all types of materials, especially those that are highly abrasive, sticky, or prone to degradation. The potential for clogging and blockages in the conveying pipes can affect system performance and require frequent interventions.

Opportunity:

⮚ Focus on Sustainability and Increased Automation

Innovations in energy-efficient pneumatic systems can appeal to industries focused on reducing their carbon footprint and operational costs. Adapting systems to meet stringent environmental regulations and reduce emissions can open new market opportunities. The trend towards increased automation in industrial processes offers opportunities for integrating advanced pneumatic conveying systems with automated production lines. Adoption of smart manufacturing practices and Industry 4.0 technologies can drive demand for advanced pneumatic conveying solutions.

Pneumatic Conveying System Market Segment Overview

Based on Technology, the market is segmented based on Positive Pressure Systems, Vacuum Systems and Combination Systems. The vacuum systems segment is dominant the pneumatic conveying system industry forecast period, driven by increasing demand for efficient and hygienic material handling solutions in several industries. Pneumatic conveying systems are an essential component of these industries’ production processes since the use of vacuum technology in pneumatic conveyors enables the gentle handling of materials, reduces the risk of contamination, and allows for precise control over the flow of materials.

By End Use

Based on End Use, the market segment has been divided into Ceramic, Pharmaceuticals, Food, Cement and Others. The food segment dominant the market. The food category generated the most income owing to its benefits, such as high reliability, increased productivity, reduced risk of material spillage, and low energy consumption. However, pharmaceutical is the fastest-growing category due to the rise in the adoption of pneumatic conveying systems in the pharmaceutical industry.

By Operating Principle

Based on Operating Principle, the market segment has been divided into Dilute Phase Conveying and Dense Phase Conveying. The dense phase conveying segment dominant the market due to its ability to handle a wide range of materials, including those that are difficult to convey using other methods. Dense phase conveying uses a high-pressure air stream to move particles or objects through a pipe, allowing for efficient and reliable transportation over long distances. This method is particularly useful for handling materials such as powders, granules, and irregularly shaped objects, which can be difficult to convey using other pneumatic conveying methods.

Global Pneumatic Conveying System Market Regional Analysis

Based on region, the global Pneumatic Conveying System Market has been divided into North America, Europe, Asia-Pacific, the Middle East & Africa, and Latin America. North America is projected to dominate the use of the Pneumatic Conveying System Market followed by the Asia-Pacific and Europe regions.

North America holds a dominant position in the Pneumatic Conveying System Market. The U.S. has a well-established industrial base with high demand for pneumatic conveying systems across various sectors including food and beverage, pharmaceuticals, chemicals, and plastics. Growing adoption of automation and smart manufacturing solutions and have strict regulatory standards that impact system design and operation. Canada’s market is influenced by its industrial activities in sectors like mining, oil and gas, and food processing and growing interest in advanced pneumatic systems for enhancing operational efficiency.

Pneumatic Conveying System Asia-Pacific Market

The Asia-Pacific region has indeed emerged as the fastest-growing market for the Pneumatic Conveying System Market industry. China has a significant demand for pneumatic conveying systems across multiple industries, including automotive, food and beverage, pharmaceuticals, and chemicals. Rapid growth in industrial activities and infrastructure development and increasing focus on modernization and integration of advanced technologies in manufacturing.

Competitive Landscape

The global Pneumatic Conveying System Market is highly competitive, with numerous players offering a wide range of software solutions. The competitive landscape is characterized by the presence of established companies, as well as emerging startups and niche players. To increase their market position and attract a wide consumer base, the businesses are employing various strategies, such as product launches, and strategic alliances.

Prominent Players:

- Nol-Tec Systems

- VAC-U-MAX

- Flexicon

- Schenck Process Holding

- Indpro Engineering Systems

- Whirl-Air-Flow Corporation

- FLSmidth

- Jenike & Johanson

- HAF Equipment

- Industrial Accessories Company

Key Development

In April 2023, Cyclonaire Corporation announced that it will exhibit its conveying solutions for various industrial applications at the International Powder and Bulk Solids Conference and Exhibition.

In January 2022, Flexicon opened a new office in Malaysia to facilitate direct sales and application engineering services in Southeast Asia; the local Malaysian staff will fully understand Flexicon’s engineering resources and experience of more than 25,000 installations worldwide.

Scope of the Report

Global Pneumatic Conveying System Market, by Technology

- Positive Pressure Systems

- Vacuum Systems

- Combination Systems

Global Pneumatic Conveying System Market, by End Use

- Ceramic

- Pharmaceuticals

- Food

- Cement

- Others

Global Pneumatic Conveying System Market, by Operating Principle

- Dilute Phase Conveying

- Dense Phase Conveying.

Global Pneumatic Conveying System Market, by Region

- North America

- US

- Canada

- Mexico

- Europe

- UK

- Germany

- France

- Italy

- Spain

- Benelux

- Nordic

- Rest of Europe

- Asia Pacific

- China

- Japan

- South Korea

- Indonesia

- Austalia

- Malaysia

- India

- Rest of Asia Pacific

- South America

- Brazil

- Argentina

- Rest of South America

- Middle East & Africa

- Saudi Arabia

- UAE

- Egypt

- South Africa

- Rest of Middle East & Africa

| Parameters | Indicators |

|---|---|

| Market Size | 2033: USD 13.65 Billion |

| CAGR (2023-2033) | 8.24% |

| Base year | 2022 |

| Forecast Period | 2023-2033 |

| Historical Data | 2021 (2017 to 2020 On Demand) |

| Report Coverage | Revenue Forecast, Competitive Landscape, Growth Factors, and Trends |

| Key Segmentations | Technology, End Use, Operating Principle |

| Geographies Covered | North America, Europe, Asia-Pacific, South America, Middle East, Africa |

| Key Vendors | Nol-Tec Systems, VAC-U-MAX, Flexicon, Schenck Process Holding, Indpro Engineering Systems, Whirl-Air-Flow Corporation, FLSmidth, Jenike & Johanson, HAF Equipment and Industrial Accessories Company |

| Key Market Opportunities | · Focus on Sustainability and Increased Automation |

| Key Market Drivers | · Technological Advancements

· Cost-Effectiveness |

REPORT CONTENT BRIEF:

- High-level analysis of the current and future Pneumatic Conveying System Market trends and opportunities

- Detailed analysis of current market drivers, restraining factors, and opportunities in the future

- Pneumatic Conveying System Market historical market size for the year 2021, and forecast from 2023 to 2033

- Pneumatic Conveying System Market share analysis at each product level

- Competitor analysis with detailed insight into its product segment, Government & Defense strength, and strategies adopted.

- Identifies key strategies adopted including product launches and developments, mergers and acquisitions, joint ventures, collaborations, and partnerships as well as funding taken and investment done, among others.

- To identify and understand the various factors involved in the global Pneumatic Conveying System Market affected by the pandemic

- To provide a detailed insight into the major companies operating in the market. The profiling will include the Government & Defense health of the company’s past 2-3 years with segmental and regional revenue breakup, product offering, recent developments, SWOT analysis, and key strategies.

Frequently Asked Questions (FAQ)

What is the growth rate of the global Pneumatic Conveying System Market?

The global Pneumatic Conveying System Market is growing at a CAGR of 8.24% over the next 10 years

Which region has the highest growth rate in the market of Pneumatic Conveying System Market?

Asia Pacific is expected to register the highest CAGR during 2023-2033

Which region has the largest share of the global Pneumatic Conveying System Market?

North America holds the largest share in 2022

Who are the key players in the global Pneumatic Conveying System Market?

Nol-Tec Systems, VAC-U-MAX, Flexicon, Schenck Process Holding, Indpro Engineering Systems, Whirl-Air-Flow Corporation, FLSmidth, Jenike & Johanson, HAF Equipment and Industrial Accessories Company are the major companies operating in the market.

Do you offer Post Sale Support?

Yes, we offer 16 hours of analyst support to solve the queries

Do you sell particular sections of a report?

Yes, we provide regional as well as country-level reports. Other than this we also provide a sectional report. Please get in contact with our sales representatives.