Factory Automation Market Overview

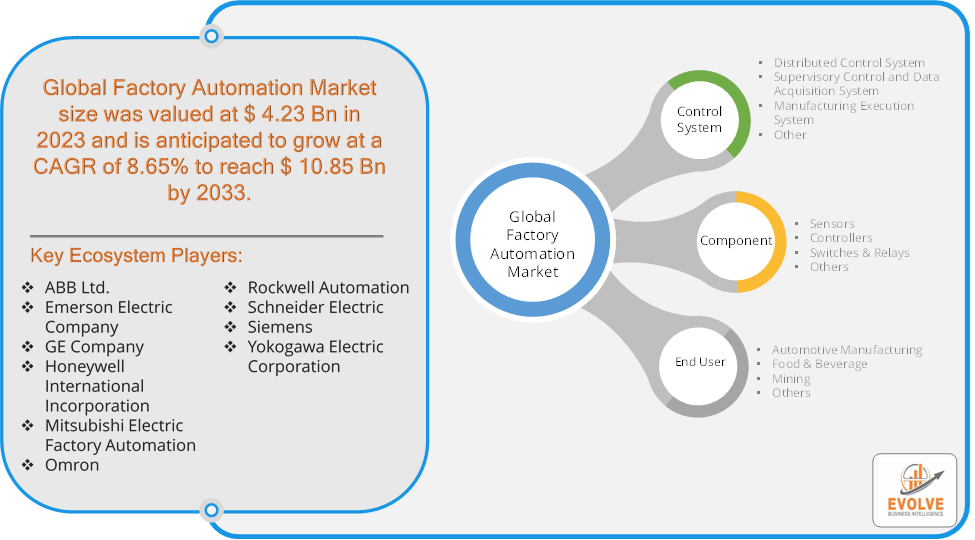

The Factory Automation Market Size is expected to reach USD 10.85 Billion by 2033. The Factory Automation Market industry size accounted for USD 4.23 Billion in 2023 and is expected to expand at a compound annual growth rate (CAGR) of 8.65% from 2023 to 2033. The Factory Automation Market refers to the market encompassing technologies, systems, and solutions used to automate manufacturing processes in factories. This includes a wide range of products such as sensors, controllers, software, and robotic systems designed to enhance production efficiency, reduce human intervention, and improve the overall manufacturing process.

The market is driven by the need for improved productivity, reduced operational costs, enhanced safety, and better quality control in manufacturing. Industries such as automotive, electronics, food and beverages, and pharmaceuticals are key contributors to the demand for factory automation. The market is also influenced by advancements in technologies like artificial intelligence, the Industrial Internet of Things (IIoT), and robotics.

Global Factory Automation Market Synopsis

The COVID-19 pandemic had a significant impact on the Factory Automation Market. The pandemic caused disruptions in global supply chains, leading to delays in the delivery of essential components and equipment used in factory automation. Many factories experienced temporary shutdowns or operated at reduced capacity, which slowed down the adoption and implementation of automation systems. Social distancing measures and workforce shortages due to lockdowns and quarantines created operational challenges, pushing companies to consider greater levels of automation to reduce dependency on human labor. The pandemic highlighted the vulnerabilities of relying heavily on human labor, accelerating the shift towards automation. Companies began to invest more in automated systems to ensure business continuity in future crises. The pandemic underscored the importance of upskilling the workforce to work alongside automated systems. Training programs and investments in human-machine collaboration tools became more prominent.

Factory Automation Market Dynamics

The major factors that have impacted the growth of Factory Automation Market are as follows:

Drivers:

Ø Technological Advancements

Innovations in robotics, artificial intelligence (AI), the Industrial Internet of Things (IIoT), and machine learning are making factory automation more sophisticated, flexible, and accessible. These technologies enable smarter, more adaptive manufacturing processes that can be easily integrated into existing systems. The shift towards mass customization and the need to quickly adapt to changing consumer demands are driving the adoption of flexible automation solutions. Automated systems can be easily reconfigured to produce different products, making them ideal for industries with varying production requirements.

Restraint:

- Perception of High Initial Costs and

The implementation of factory automation systems requires significant upfront investment in technology, machinery, and infrastructure. This high initial cost can be a barrier, especially for small and medium-sized enterprises (SMEs) with limited financial resources. Integrating new automation technologies with existing systems and machinery can be complex and time-consuming. The need for customization, along with potential compatibility issues between different systems, can deter companies from adopting automation.

Opportunity:

⮚ Advancements in Artificial Intelligence (AI) and Machine Learning

AI and machine learning are enhancing the capabilities of automation systems, allowing for predictive maintenance, quality control, and optimized production processes. These advancements offer significant opportunities for developing smarter, more adaptive automation solutions. The use of data analytics and digital twins—virtual replicas of physical assets—can enhance decision-making, simulation, and optimization in manufacturing. Opportunities exist in developing solutions that leverage these technologies to improve operational efficiency and predictive capabilities.

Factory Automation Market Segment Overview

Based on Control System, the market is segmented based on Distributed Control System, Supervisory Control and Data Acquisition System, Manufacturing Execution System and Other. The Supervisory Control and Data Acquisition System segment dominant the market. SCADA systems provide real-time visibility and control over industrial operations, which is essential for maintaining process stability and quality. SCADA systems help in improving operational efficiency, reducing downtime, and enhancing safety by monitoring and controlling industrial processes in real-time.

By Component

Based on Component, the market segment has been divided into Sensors, Controllers, Switches & Relays and Others. The Controllers segment dominant the market. Controllers designed to manage the motion of machinery and equipment, such as robotic arms and conveyor systems. The demand for efficient and reliable automation solutions drives the growth of the Controllers segment.

By End User

Based on End Users, the market segment has been divided into Automotive Manufacturing, Food & Beverage, Mining and Others. The Automotive Manufacturing segment dominant the market. Automation improves production speed and reduces cycle times, which is crucial for meeting high demand and competitive pressures. Automation ensures consistent quality and precision in manufacturing, which is essential for the automotive industry’s stringent standards.

Global Factory Automation Market Regional Analysis

Based on region, the global Factory Automation Market has been divided into North America, Europe, Asia-Pacific, the Middle East & Africa, and Latin America. North America is projected to dominate the use of the Factory Automation Market followed by the Asia-Pacific and Europe regions.

North America holds a dominant position in the Factory Automation Market. North America, particularly the United States and Canada, is a leading market for factory automation due to its advanced manufacturing sector, high adoption of technology, and strong focus on Industry 4.0. The presence of major industrial companies, technological innovation, high labor costs, and a focus on improving operational efficiency drive market growth and have significant investments in robotics, AI, and IoT technologies. There’s also a strong emphasis on cybersecurity and integrating smart manufacturing solutions.

Factory Automation Asia-Pacific Market

The Asia-Pacific region has indeed emerged as the fastest-growing market for the Factory Automation Market industry. Asia-Pacific is the fastest-growing market for factory automation, driven by rapid industrialization, technological advancements, and increasing investments in manufacturing infrastructure. Key countries include China, Japan, South Korea, and India and significant investments in robotics, IIoT, and smart manufacturing technologies. There is also a focus on improving productivity and quality in diverse industries, from electronics to automotive.

Competitive Landscape

The global Factory Automation Market is highly competitive, with numerous players offering a wide range of software solutions. The competitive landscape is characterized by the presence of established companies, as well as emerging startups and niche players. To increase their market position and attract a wide consumer base, the businesses are employing various strategies, such as product launches, and strategic alliances.

Prominent Players:

- ABB Ltd.

- Emerson Electric Company

- GE Company

- Honeywell International Incorporation

- Mitsubishi Electric Factory Automation

- Omron

- Rockwell Automation

- Schneider Electric

- Siemens

- Yokogawa Electric Corporation

Key Development

In May 2022– Honeywell and DENSO Corporation collaborated on an electric motor for the Lilium Jet. This is the first joint venture between the two companies and marks DENSO’s entry into the aerospace industry. The first ever eVTOL (electric vertical takeoff and landing) jet was created by Lilium. Companies will work together to integrate the electric motor into Lilium’s aircraft engines.

Scope of the Report

Global Factory Automation Market, by Control System

- Distributed Control System

- Supervisory Control and Data Acquisition System

- Manufacturing Execution System

- Other

Global Factory Automation Market, by Component

- Sensors

- Controllers

- Switches & Relays

- Others

Global Factory Automation Market, by End User

- Automotive Manufacturing

- Food & Beverage

- Mining

Global Factory Automation Market, by Region

- North America

- US

- Canada

- Mexico

- Europe

- UK

- Germany

- France

- Italy

- Spain

- Benelux

- Nordic

- Rest of Europe

- Asia Pacific

- China

- Japan

- South Korea

- Indonesia

- Austalia

- Malaysia

- India

- Rest of Asia Pacific

- South America

- Brazil

- Argentina

- Rest of South America

- Middle East & Africa

- Saudi Arabia

- UAE

- Egypt

- South Africa

- Rest of Middle East & Africa

| Parameters | Indicators |

|---|---|

| Market Size | 2033: USD 10.85 Billion |

| CAGR (2023-2033) | 8.65% |

| Base year | 2022 |

| Forecast Period | 2023-2033 |

| Historical Data | 2021 (2017 to 2020 On Demand) |

| Report Coverage | Revenue Forecast, Competitive Landscape, Growth Factors, and Trends |

| Key Segmentations | Control System, Component, End User |

| Geographies Covered | North America, Europe, Asia-Pacific, South America, Middle East, Africa |

| Key Vendors | ABB Ltd., Emerson Electric Company, GE Company, Honeywell International Incorporation, Mitsubishi Electric Factory Automation, Omron, Rockwell Automation, Schneider Electric, Siemens and Yokogawa Electric Corporation |

| Key Market Opportunities | · Advancements in Artificial Intelligence (AI) and Machine Learning

· Growing Focus on Data Analytics and Digital Twins |

| Key Market Drivers | · Technological Advancements

· Need for Flexible and Scalable Manufacturing |

REPORT CONTENT BRIEF:

- High-level analysis of the current and future Factory Automation Market trends and opportunities

- Detailed analysis of current market drivers, restraining factors, and opportunities in the future

- Factory Automation Market historical market size for the year 2021, and forecast from 2023 to 2033

- Factory Automation Market share analysis at each product level

- Competitor analysis with detailed insight into its product segment, Government & Defense strength, and strategies adopted.

- Identifies key strategies adopted including product launches and developments, mergers and acquisitions, joint ventures, collaborations, and partnerships as well as funding taken and investment done, among others.

- To identify and understand the various factors involved in the global Factory Automation Market affected by the pandemic

- To provide a detailed insight into the major companies operating in the market. The profiling will include the Government & Defense health of the company’s past 2-3 years with segmental and regional revenue breakup, product offering, recent developments, SWOT analysis, and key strategies.

Frequently Asked Questions (FAQ)

What is the growth rate of the global Factory Automation Market?

The global Factory Automation Market is growing at a CAGR of 8.65% over the next 10 years

Which region has the highest growth rate in the market of Factory Automation Market?

Asia Pacific is expected to register the highest CAGR during 2023-2033

Which region has the largest share of the global Factory Automation Market?

North America holds the largest share in 2022

Who are the key players in the global Factory Automation Market?

ABB Ltd., Emerson Electric Company, GE Company, Honeywell International Incorporation, Mitsubishi Electric Factory Automation, Omron, Rockwell Automation, Schneider Electric, Siemens and Yokogawa Electric Corporation are the major companies operating in the market.

Do you offer Post Sale Support?

Yes, we offer 16 hours of analyst support to solve the queries

Do you sell particular sections of a report?

Yes, we provide regional as well as country-level reports. Other than this we also provide a sectional report. Please get in contact with our sales representatives.