Aluminum Diecasting Machines Market Overview

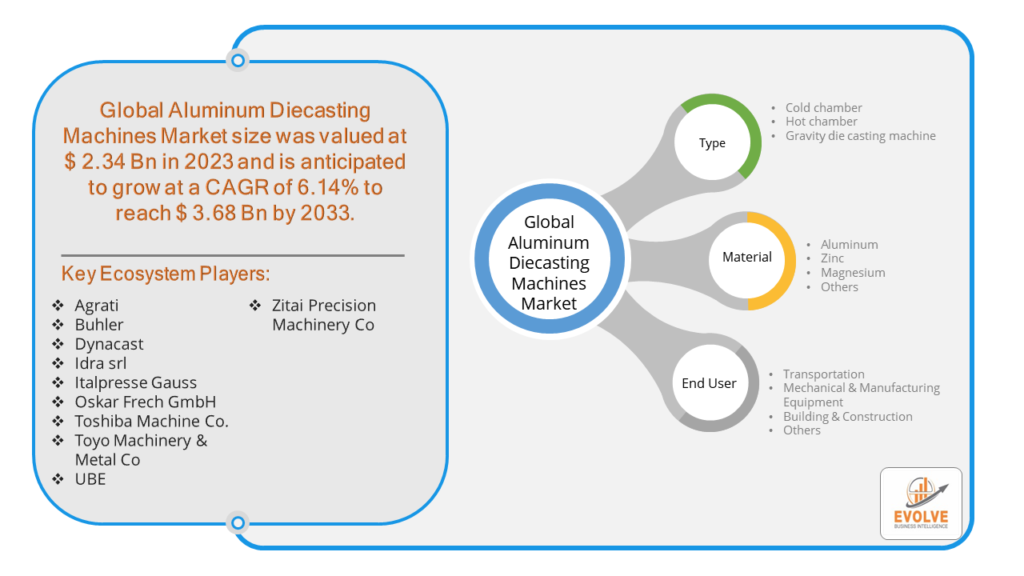

The Aluminum Diecasting Machines Market Size is expected to reach USD 3.68 Billion by 2033. The Aluminum Diecasting Machines Market industry size accounted for USD 2.34 Billion in 2023 and is expected to expand at a compound annual growth rate (CAGR) of 6.14% from 2023 to 2033. The Aluminum Diecasting Machines Market refers to the market for machines used in the process of die casting aluminum alloys. Die casting is a manufacturing process that is used to produce geometrically complex metal parts through the use of reusable molds, called dies. In the case of aluminum die casting, molten aluminum is injected into the dies under high pressure, which allows for the production of parts with high precision and surface finish.

The market is driven by the automotive industry, as well as by the demand for lightweight and durable parts in other industries such as aerospace, electronics, and consumer goods. Key players in the market include manufacturers of diecasting machines and related equipment, who cater to the diverse needs of industries globally.

Global Aluminum Diecasting Machines Market Synopsis

The COVID-19 pandemic had a significant impact on the Aluminum Diecasting Machines Market. The pandemic disrupted global supply chains, affecting the availability of raw materials and components necessary for manufacturing diecasting machines. This led to delays in production and delivery of machines. Manufacturing facilities faced operational challenges due to lockdown measures, social distancing requirements, and reduced workforce capacity. This impacted production schedules and the ability to meet customer demand. Some manufacturers shifted their focus to producing components for medical equipment and other essential products, reducing demand for automotive and other industrial parts. Companies had to implement new safety measures and protocols to protect workers, which affected productivity and efficiency.

Aluminum Diecasting Machines Market Dynamics

The major factors that have impacted the growth of Aluminum Diecasting Machines Market are as follows:

Drivers:

Ø Technological Advancements

Technological advancements in diecasting machines, such as improvements in automation, precision, and energy efficiency, drive the market. Manufacturers are continuously developing new technologies to enhance productivity and reduce production costs. Increasing environmental regulations and the focus on sustainability are prompting industries to adopt lightweight materials like aluminum, which can reduce fuel consumption and greenhouse gas emissions in vehicles and machinery. Infrastructure development projects worldwide are driving the demand for construction equipment and machinery, which often use diecast aluminum components.

Restraint:

- Perception of High Initial Investment

Diecasting machines require significant initial investment, which can be a barrier for small and medium-sized enterprises (SMEs) and startups looking to enter the market. Diecasting machines are technologically advanced and require skilled operators to ensure efficient operation. The complexity of the machines can limit adoption, especially in regions with a shortage of skilled labor. Diecasting machines consume a significant amount of energy, particularly those used for high-pressure die casting. Energy costs and environmental concerns related to energy consumption can restrain market growth.

Opportunity:

⮚ Automotive Lightweighting

With the automotive industry’s increasing focus on lightweighting to improve fuel efficiency and reduce emissions, there is a growing demand for aluminum diecast parts. This trend presents a significant opportunity for diecasting machine manufacturers. The renewable energy sector, including wind and solar power, requires aluminum components for its equipment. This presents opportunities for diecasting machines in producing parts for wind turbines, solar panels, and energy storage systems.

Aluminum Diecasting Machines Market Segment Overview

By Type

By Material

Based on Material, the market segment has been divided into the Aluminum, Zinc, Magnesium and Others. The Aluminum segment dominant the market. Aluminum diecasting machines operate using both cold chamber and sometimes hot chamber technologies, depending on the specific aluminum alloy being used.

By End User

Based on End Users, the market segment has been divided into the Transportation, Mechanical & Manufacturing Equipment, Building & Construction and Others. The Transportation segment dominant the market. It’s driven by the increasing adoption of lightweight materials in automotive and aerospace industries. As technological advancements continue and industries focus on sustainability, the demand for aluminum diecast components and the machines that produce them is expected to rise.

Global Aluminum Diecasting Machines Market Regional Analysis

Based on region, the global Aluminum Diecasting Machines Market has been divided into North America, Europe, Asia-Pacific, the Middle East & Africa, and Latin America. North America is projected to dominate the use of the Aluminum Diecasting Machines Market followed by the Asia-Pacific and Europe regions.

North America holds a dominant position in the Aluminum Diecasting Machines Market. United States major demand from the automotive, aerospace, and industrial sectors. The shift towards lightweight materials in automotive and aerospace industries supports the market growth.

Aluminum Diecasting Machines Asia-Pacific Market

The Asia-Pacific region has indeed emerged as the fastest-growing market for the Aluminum Diecasting Machines Market industry. China is the largest producer and consumer of diecasting machines and diecast aluminum parts. The automotive industry in China drives significant demand, supported by rapid industrialization and infrastructure development. Also India is growing automotive and industrial sectors are driving the demand for diecasting machines. The government’s initiatives towards manufacturing and infrastructure development further boost the market.

Competitive Landscape

The global Aluminum Diecasting Machines Market is highly competitive, with numerous players offering a wide range of software solutions. The competitive landscape is characterized by the presence of established companies, as well as emerging startups and niche players. To increase their market position and attract a wide consumer base, the businesses are employing various strategies, such as product launches, and strategic alliances.

Prominent Players:

- Agrati

- Buhler

- Dynacast

- Idra srl

- Italpresse Gauss

- Oskar Frech GmbH

- Toshiba Machine Co.

- Toyo Machinery & Metal Co

- UBE

- Zitai Precision Machinery Co

Scope of the Report

Global Aluminum Diecasting Machines Market, by Type

- Cold chamber

- Hot chamber

- Gravity die casting machine

Global Aluminum Diecasting Machines Market, by Material

- Aluminum

- Zinc

- Magnesium

- Others

Global Aluminum Diecasting Machines Market, by End User

- Transportation

- Mechanical & Manufacturing Equipment

- Building & Construction

- Others

Global Aluminum Diecasting Machines Market, by Region

- North America

- US

- Canada

- Mexico

- Europe

- UK

- Germany

- France

- Italy

- Spain

- Benelux

- Nordic

- Rest of Europe

- Asia Pacific

- China

- Japan

- South Korea

- Indonesia

- Austalia

- Malaysia

- India

- Rest of Asia Pacific

- South America

- Brazil

- Argentina

- Rest of South America

- Middle East & Africa

- Saudi Arabia

- UAE

- Egypt

- South Africa

- Rest of Middle East & Africa

| Parameters | Indicators |

|---|---|

| Market Size | 2033: $3.68 Billion/strong> |

| CAGR | 6.14% CAGR (2023-2033) |

| Base year | 2022 |

| Forecast Period | 2023-2033 |

| Historical Data | 2021 |

| Report Coverage | Revenue Forecast, Competitive Landscape, Growth Factors, and Trends |

| Key Segmentations | Type, Material, End User |

| Geographies Covered | North America, Europe, Asia-Pacific, Latin America, Middle East, Africa |

| Key Vendors | Agrati, Buhler, Dynacast, Idra srl, Italpresse Gauss, Oskar Frech GmbH, Toshiba Machine Co., Toyo Machinery & Metal Co, UBE and Zitai Precision Machinery Co. |

| Key Market Opportunities | • Automotive Lightweighting • Renewable Energy |

| Key Market Drivers | • Technological Advancements • Rising Investment in Infrastructure |

REPORT CONTENT BRIEF:

- High-level analysis of the current and future Aluminum Diecasting Machines Market trends and opportunities

- Detailed analysis of current market drivers, restraining factors, and opportunities in the future

- Aluminum Diecasting Machines Market historical market size for the year 2021, and forecast from 2023 to 2033

- Aluminum Diecasting Machines Market share analysis at each product level

- Competitor analysis with detailed insight into its product segment, Government & Defense strength, and strategies adopted.

- Identifies key strategies adopted including product launches and developments, mergers and acquisitions, joint ventures, collaborations, and partnerships as well as funding taken and investment done, among others.

- To identify and understand the various factors involved in the global Aluminum Diecasting Machines Market affected by the pandemic

- To provide a detailed insight into the major companies operating in the market. The profiling will include the Government & Defense health of the company’s past 2-3 years with segmental and regional revenue breakup, product offering, recent developments, SWOT analysis, and key strategies.

Frequently Asked Questions (FAQ)

2. What is the growth rate of the global Aluminum Diecasting Machines Market?

- The global Aluminum Diecasting Machines Market is growing at a CAGR of 6.14% over the next 10 years

3. Which region has the highest growth rate in the market of Aluminum Diecasting Machines Market?

- Asia Pacific is expected to register the highest CAGR during 2023-2033

4. Which region has the largest share of the global Aluminum Diecasting Machines Market?

- North America holds the largest share in 2022

5. Who are the key players in the global Aluminum Diecasting Machines Market?

Agrati, Buhler, Dynacast, Idra srl, Italpresse Gauss, Oskar Frech GmbH, Toshiba Machine Co., Toyo Machinery & Metal Co, UBE and Zitai Precision Machinery Co. are the major companies operating in the market