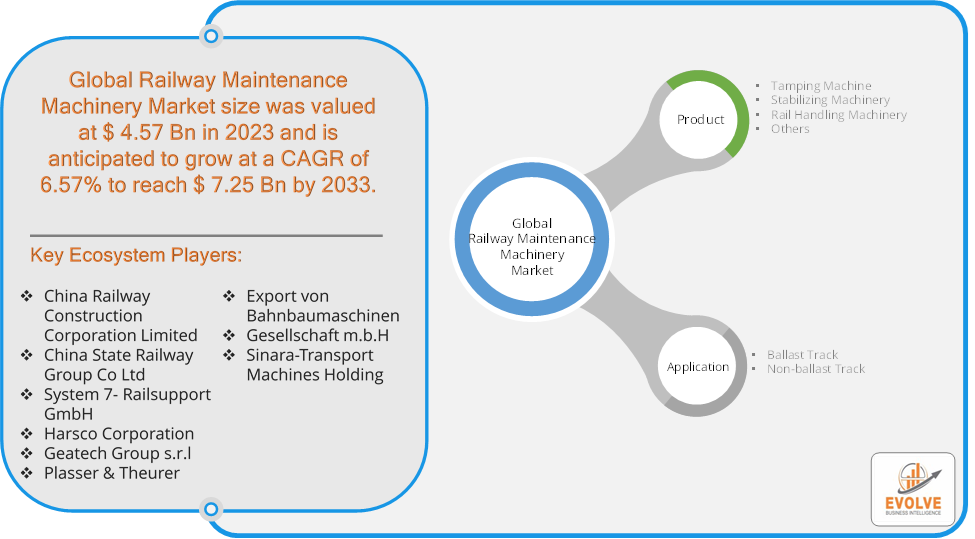

Evolve Business Intelligence has published a research report on the Global Railway Maintenance Machinery Market, 2023–2033. The global Railway Maintenance Machinery Market is projected to exhibit a CAGR of around 6.57% during the forecast period of 2023 to 2033.

Evolve Business Intelligence has recognized the following companies as the key players in the global Railway Maintenance Machinery Market: China Railway Construction Corporation Limited, China State Railway Group Co Ltd, System 7- Railsupport GmbH, Harsco Corporation, Geatech Group s.r.l, Plasser & Theurer, Export von Bahnbaumaschinen, Gesellschaft m.b.H and Sinara-Transport Machines Holding.

More Information: https://evolvebi.com/report/railway-maintenance-machinery-market-analysis/

More Information: https://evolvebi.com/report/railway-maintenance-machinery-market-analysis/

Market Highlights

The Global Railway Maintenance Machinery Market is projected to be valued at USD 7.25 Billion by 2033, recording a CAGR of around 6.57% during the forecast period. The Railway Maintenance Machinery Market refers to the global industry focused on the production, distribution, and servicing of machinery and equipment used for the maintenance and repair of railway infrastructure. This market encompasses a wide range of specialized machines designed for tasks such as track inspection, rail grinding, tamping, ballast cleaning, and more, ensuring the safe and efficient operation of rail networks.

The market is driven by factors such as the expansion of rail networks, increasing focus on safety and efficiency, technological advancements in machinery, and the growing need for automated and efficient maintenance solutions. It is also influenced by investments in high-speed rail and the modernization of existing railway infrastructure. Key players in the market include manufacturers of railway maintenance machinery, service providers, and suppliers of components and parts.

The COVID-19 pandemic had a significant impact on the Railway Maintenance Machinery Market. The pandemic caused widespread disruptions in global supply chains, affecting the production and delivery of railway maintenance machinery. Manufacturing facilities were forced to close or operate at reduced capacity, leading to delays in the production and shipment of machinery and components. With reduced rail traffic during the pandemic, many railway operators prioritized essential maintenance over new investments or non-essential upgrades. This led to a focus on maintaining existing infrastructure rather than expanding or modernizing, affecting the market for certain types of maintenance machinery. The pandemic slowed down research and development activities within the industry. Companies were forced to cut costs, which often meant reducing investments in innovation and the development of new technologies in railway maintenance machinery. The pandemic has led to strategic shifts in the railway industry, with increased emphasis on automation, remote monitoring, and predictive maintenance. This could drive future demand for advanced maintenance machinery, despite the initial setbacks caused by COVID-19.

Segmental Analysis

The global Railway Maintenance Machinery Market has been segmented based on Product Type and Application.

Based on Product Type, the Railway Maintenance Machinery Market is segmented into Tamping Machine, Stabilizing Machinery, Rail Handling Machinery and Others. The Tamping Machine segment is anticipated to dominate the market.

Based on Application, the global Railway Maintenance Machinery Market has been divided into Ballast Track and Non-ballast Track. The Ballast Track segment is anticipated to dominate the market.

More Information: https://evolvebi.com/report/railway-maintenance-machinery-market-analysis/

Regional Analysis

The Railway Maintenance Machinery Market is divided into five regions: North America, Europe, Asia-Pacific, South America, and the Middle East, & Africa. North America has a well-established railway infrastructure, particularly in the U.S. and Canada. The region is focused on maintaining and upgrading its extensive freight rail network, which is one of the most advanced in the world. The focus on enhancing rail safety, increasing freight transportation, and government investments in infrastructure are key drivers in this region. The adoption of advanced technologies and automation in railway maintenance machinery is also growing. Europe has a mature railway network, with extensive passenger and freight rail systems. Countries like Germany, France, and the UK are leaders in rail technology and innovation and focus on high-speed rail and modernization of existing infrastructure drives market growth. Asia-Pacific is the fastest-growing region in the Railway Maintenance Machinery Market, driven by rapid urbanization, economic growth, and significant investments in rail infrastructure, particularly in China, India, and Southeast Asia and the expansion of urban rail networks, high-speed rail projects, and government initiatives to improve public transportation are major drivers in this region. China, in particular, has a massive high-speed rail network that requires continuous maintenance. The Middle East and Africa region has a mix of developing and mature railway markets. While some countries have well-developed rail systems, others are in the early stages of developing their networks. Latin America has a developing railway network, with some countries like Brazil and Argentina having relatively established rail systems. However, the region’s rail infrastructure is generally underdeveloped compared to other parts of the world.